CNC Lathes for every Application

With over 150 years of experience in turning, DMG MORI offers comprehensive technological expertise, reflected in around 20 different series of CNC lathes: As a machine tool manufacturer, we cover a wide range of applications, from versatile universal lathes and innovative turn-mill centers (Turn & Mill) to highly economical production turning.

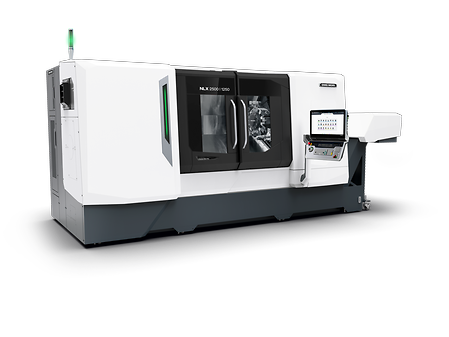

Top-Seller

From the lathe to the modern CNC lathe

The basic principle of turning has not changed since the classic lathe: A workpiece is rotated via the main spindle and a cutting movement is generated through contact with a turning tool. The tool, in turn, makes an advancing movement so that the workpiece is machined over a machine-dependent longitudinal path as well as the turning diameter. Modern CNC lathes go far beyond this simple principle and are considered ever more flexible miracles of precision.

Overview

Important questions about CNC turning

What lathes are available?

The increasing variety of applications has meant that turning has continued to evolve. Therefore, in addition to universal CNC lathes, turn-mill centers and production lathes are a common standard. In each of these areas, DMG MORI offers series that stand for performance and precision – from the CLX, CTX and NLX models in universal turning and the turn-mill series CLX & CTX TC and NTX to production lathes, including the SPRINT models, the NZ platform and the WASINO series.

What is 6-sided complete machining?

6-sided complete machining involves the complete finishing of complex workpieces from all six sides in one work area without the use of automation. This is initially done by machining on the main spindle. The workpiece is automatically transferred to the counter-spindle for back machining. Turning and milling operations can be carried out with one or more turrets on both the main and counter spindles. DMG MORI integrates the milling on the CLX TC, CTX beta TC, CTX gamma TC and NTX turn-mill machines (Turn & Mill) to complete this process. Here, the compactMASTER turn-mill spindle used with a B-axis enables a milling functionality that is comparable to a universal milling machine.

What is production turning?

In production turning, the focus is on economical large series production. To make this possible when machining more complex workpieces, DMG MORI offers lathes such as the NZ platform, the SPRINT and MULTISPRINT models. They have more than one tool carrier, such as turrets, including powered tools. The NZ platform, for example, can use up to four turrets. Bar loaders or robot-supported workpiece handling systems also ensure a constant supply of material.

What is the work spindle?

The work spindle or main and counter spindle of a lathe has a lathe chuck in which the raw material is held. The speed and thus the resulting torque depends on the machining process.

What is a turret?

The tools required for machining are housed in the lathe’s turret and are turned towards the workpiece according to the work step. The turret has a certain number of tool slots. It is often possible to set up powered tools that can also perform milling operations on the workpiece. Off-center milling operations for complex workpieces can also be carried out using a Y-axis.

Universal turning: Performance and precision in metalworking

Quality-oriented universal turning requires stable, low-vibration lathes that offer maximum performance and precision at all times. The prerequisites for this are inherently rigid machine beds, robust guideways or linear guides and high-precision position measuring systems. Turrets with powered tools or a tailstock and/or a steady rest for machining long workpieces also increase the variety of machining.

Speed, turning diameter, distance between centers – the right machine data for every application

Both in the entry-level range with the attractively priced CLX models and in the high-tech segment with the proven CTX and NLX lathes, DMG MORI sets standards in the machining of demanding precision workpieces. A powerful main spindle ensures that all models offer the right speed and the required torque. Distance between centers, center height or swing diameter – the variety of models offers suitable sizes for every application.

- Precision through inherently rigid machine beds and robust guideways or linear guides

- Variety of machining options through turret with powered tools and Y-axis

- Maximum performance through powerful spindles

Turn & Mill: 6-sided complete machining of complex workpieces

In order to produce complex geometries, for a long time it was common to first turn workpieces and then finish them on milling machines. DMG MORI was one of the first manufacturers to integrate both technologies in one workspace. The advantage: Turning and milling in one work area reduces throughput times. Fewer manual re-clamping processes minimize the potential for errors. This in turn increases component quality.

The CLX 450 TC is the entry-level tool for turning and milling. The numerous models of the CTX beta TC, CTX gamma TC and NTX series also offer a suitable machine for every application in this area – regardless of the weight of the workpieces. The Turn & Mill machines are equipped with the compactMASTER milling spindle.

Complex geometries thanks to the compactMASTER spindle

The patented compactMASTER milling spindle is the heart and soul of the Turn & Mill models from DMG MORI. Its ultra-compact dimensions and its large swivel range enable optimal use of the working space. Depending on the machine model, a disk magazine or chain magazine automatically supplies the spindle with tools.

- Short throughput times thanks to complete machining in one work area

- Minimized potential for errors due to fewer manual re-clamping processes

- Complex geometries through turning and milling including Y-axis

Horizontal production turning: Economical large series production

Production turning is characterized by the efficient manufacture of large quantities. With additional turrets or spindles, as well as powered tools, even complex turned parts can be machined from bars quickly and economically. Bar loaders ensure a constant supply of material so that machine run times are maximized. Various robot-supported automation solutions can be used to machine chuck components.

DMG MORI has been a pioneer in production turning for decades. Solidly constructed machines ensure rigidity and precision in machining. With the NZ series, for example, up to four turrets including Y-axis can be used in the work area. The WASINO automatic lathes, on the other hand, represent maximum accuracy, especially in series production in the automotive sector.

- Efficient production of large quantities

- High component complexity due to additional turrets and powered tools

- Constant replenishment using a bar loader

Videos showing our Turning Machines

Automated production on lathes

In global competition, productive manufacturing solutions are required to remain competitive in the long term. Above all, automated manufacturing is increasingly finding its way into production. DMG MORI has also been supporting this trend in turning for many years. First, bar processing was automated using bar loaders and integrated robots for feeding and removing workpieces. This was followed by gantry loaders for chuck machining. Today, holistic automation solutions such as the Robo2Go models, the MATRIS light and the IMTR complete DMG MORI’s portfolio for implementing fully automatic processes in turning and turning/milling.