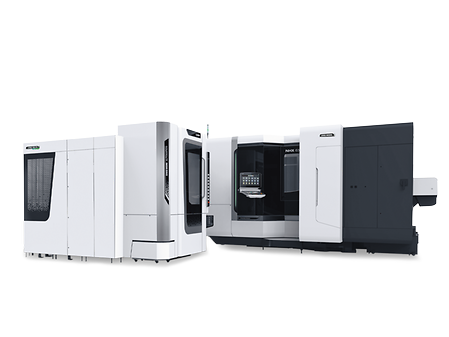

NHX 6300

Fusing a diverse range of functions with elegant design

Highlights

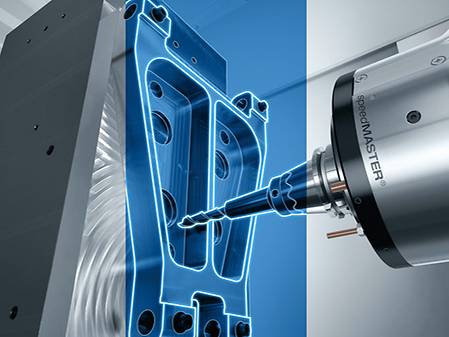

High speed

- Rapid traverse rate X-, Y- and Z-axes: 2,362.2 ipm

- Max. acceleration X-, Y- and Z-axes: 0.64 / 0.93 / 0.70 G (20.7 / 29.9 / 22.6 ft/s2)

- Cutting feedrate X-, Y- and Z-axes: 2,362.2 ipm

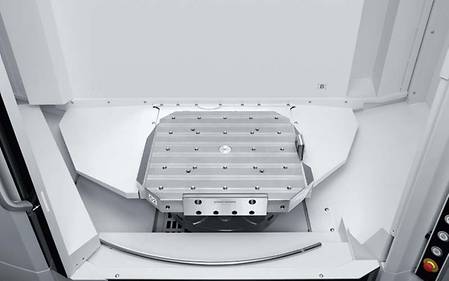

High rigidity

- Thick, high-rigidity bed

- The 3-point support structure ensures a stable machine installation

- Machining with shorter tools

High-precision equipment

- High-resolution direct scale feedback

- Draw-back function for through spindle coolant

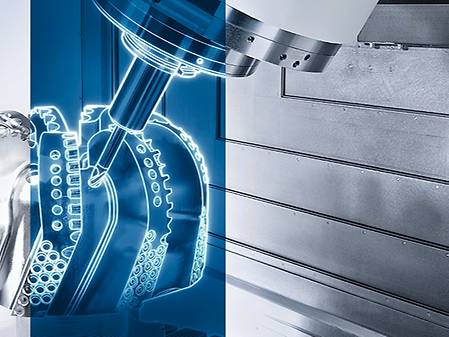

Sample applications

Automation

Standard automation and customized solutions in VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customized automation solution for flexible manufacturing systems:

The entry-level flexible pallet storage solution for up to 4 machines

- Handling of workpieces up to ø 2,000 x 1,600 mm, 3,000 kg

- Up to 11 pallets and max. four machines with two setup stations

- Operate via machine HMI or via the DMGMORI master computer HMI

- MCC-TMS tool management system

Holistic automation on the shop floor

- Collaborative automation solution with free layout design

- Omnidirectional movement for minimal space requirements (turning radius 0m)

- Basis for additional tasks, e.g. B. tool handling, chip disposal, etc.

- Material transport from Euro pallets 1,200 x 800 mm

- Maximum transport weight of up to 2,000 kg

- Security based on Sick and Siemens technology

- Autonomous transport of material pallets

- Transport of different load carriers

- Integration into DMG MORI automation systems for workpiece handling – exchange of finished part and raw part pallets

- Integration into existing processes

- Scalable and expandable at a later date

- Autonomous transport of chip containers

- Automatic transport order from the master computer

- Extended autonomy of the machine tool

- Material and chip transport can be combined

- Tool identification in the standard

- Autonomous transport and exchange of tools between machines and tool storage systems

- Max. tool dimensions ø 280 / 400 mm

- Max. tool weight 30 kg

- Transport weight 720 kg (24× 30 kg)

- Maximum number of tools: 24 pcs

Linear pallet storage solution for up to 8 machines and 99 pallets

- Handling of workpieces up to ø 3,400 x 2,000 mm, 10,000 kg

- Very flexible pallet pool system with up to 8 machines, 99 pallets and 5 setup stations

- Handling of up to three different pallet sizes possible in one system (2 sizes for machine pallets and one size for material pallets)

- Control directly via DMG MORI master computer software LPS

- Integration into customer network / workflow possible

- Monitoring and management tools for all relevant areas (planning, workpieces, clamping, tools, etc.)

- Tool management system MCC-TMS

Control & software

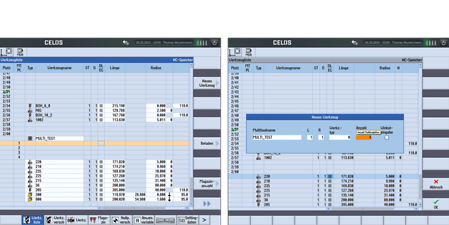

CELOS

Integrated digitization of the DMG MORI machines & the shop floor:

- CELOS Machine: APP-based user interface with access to all production-related information

- CELOS Manufacturing: 27 CELOS APPs for the optimal preparation & processing of orders

- Digital Factory: Continuous digital workflows from planning to production & service

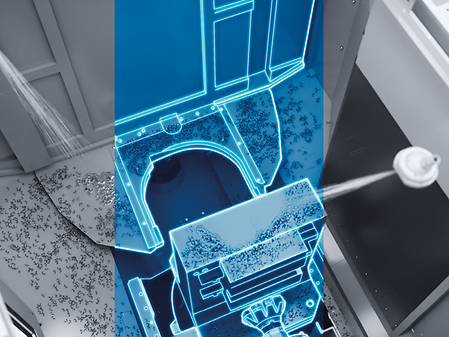

- Intelligent algorithms detect chip nests and control the moving rinsing nozzles during the machining

- Continuous optimization of the flushing strategy with a simple operation

- Resource-saving due to the precise control of the rinsing nozzles

- Manual rinsing of the machine room by employees significantly minimized

- No machine downtime for machine room cleaning

- Vibration sensors in the milling spindle

- Various indicators to display the vibration status

- New machining proposal to reduce vibrations

- With the edit function, the new machining state is easily applied to your program

- More productive cutting condition with less vibration

- Automatic suggestions for suitable process parameter

- The simple visualization serves as an orientation aid for machine operators

- Solutions for a safe process and for the efficient use of important machining steps

- Applications: cone cleaning, tool data monitoring, safe withdrawal movement, tapping, deep hole drilling, external thread and spigot milling, internal thread and circular milling, reverse countersink cycle

- 12 stored machining strategies for stock removal, deep hole drilling, Pocket milling machines*

- Runtime optimization according to individual application

- Safe retraction after program break

- Tool data monitoring

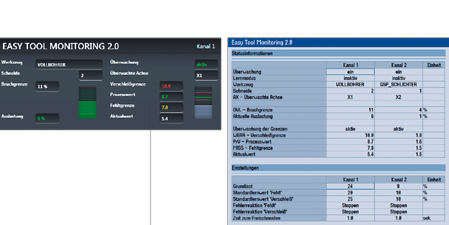

- Prevention of damage due to tool breakage or tool overload

- Sensorless with automated learning of load limits

- For turning, milling and drilling (up to 3 mm diameter)

- NEW: User interface on CELOS SideScreen

- NEW: Powerful algorithm for efficient monitoring after the first workpiece

- Protection Package: Perfect supplement to MPC Lathes. Price advantage (approx. 40%)

- Save the monitoring limits for each tool and every cutting edge in the program

- By pushing the associated key the X- axis and the Y-axis travel to the positive end-positions for external machining

- Ideally suited to prepare the work space for set-up and alternatively also as an emergency rescue function.

- Easy operation when setting up multi - channel machinery

- Possibilty of a fast response during external machining as a rescue function

- Efficient use of multi-tip turning tools with more than one cutting edge on turn & mill

- Several "sister tools" on one main tool holder

- Reduction of tool change times

- Saves tool magazine space

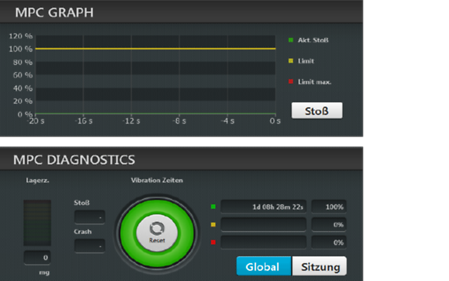

- Vibration monitoring in the process

- Rapid shutdown in case of a crash

- Manual retraction even in swiveled machining plane

- NEW: Torque monitoring

- New: Recommended with Protection Package for CTX TC machines

- Avoiding tool breakage

- Increase in machine availability

- Damage reduction

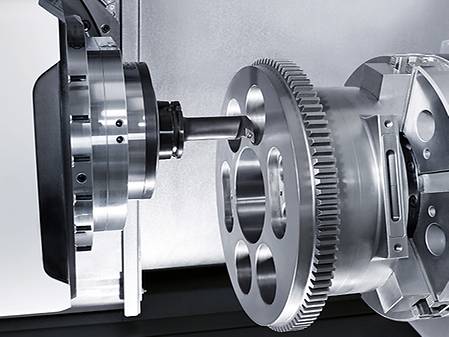

- With interpolation turning, the tool cutter follows a circular movement, where the cutter is always oriented towards the center Of the circle.

- Possible for external and internal machining

- Synchronization and tool path controlled by the cycle

- NEW: in version 2.0 complex turning contours are possible (currently only available on the DMU 50, other machine types will follow)

- Easy manufacturing of sealing surfaces where milling operation might not be possible.

- Complete component processing in one clamping possible

- Reduced investment costs for tools

- Process-oriented adjustment of the feed rate n relation to the table loading

- Minimization of machining time with maximization of the component quality

- NEW: Now also available for CTX TC. Ideal machining result with the highest machine dynamics*

*without consideration of feed weight

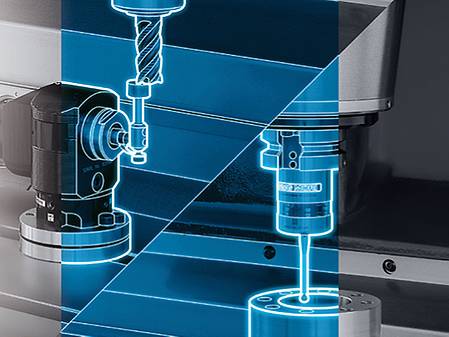

- Manual tool length measurement and workpiece centering in simple steps

- Guided instructions in the measurement. Short set-up times with high operational safety

- Shorter set-up times

- No great experience necessary to take Measurements

Service & training

Downloads & Technical Data

Special technical articles, analyses, and background information on topics that move our industry.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Get access to many useful digital functions and services and have all important data at a glance. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Unlock access to your Share Hub and many other functions and services. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

For general enquiries, please use our contact form.

For service and spare parts enquiries please use the my DMG MORI portal: https://us.mydmgmori.com/

Thank you very much for your interest in our products.

To download our brochures please fill in the form below.

If you accept the storage of cookies, this form appears only once during your visit.