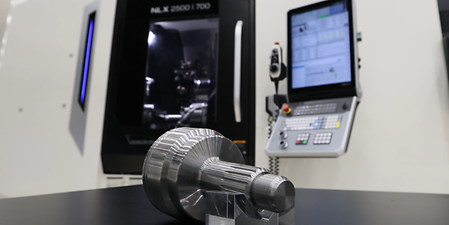

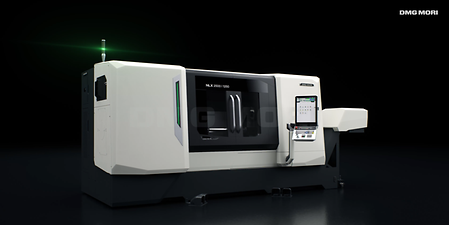

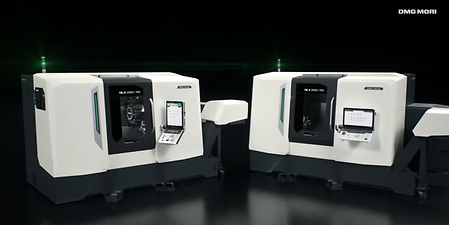

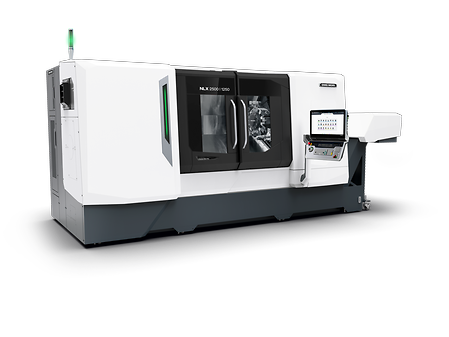

NLX 2500 2nd Generation

Rebirth of DMG MORI’s bestseller – completely modernized

Highlights

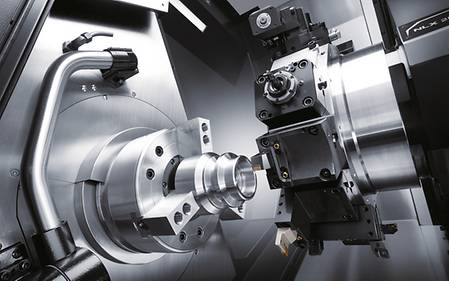

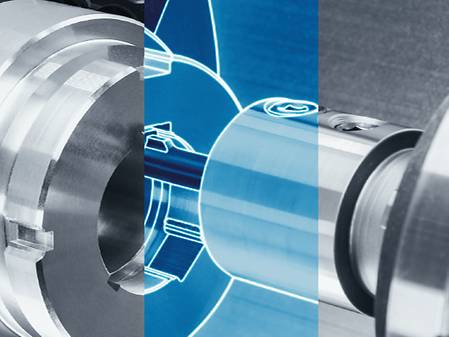

6-sided complete machining of workpieces up to Ø 366 x 1,258 mm with +/- 60 mm Y-axis

- MASTER spindles with a 36-month warranty and unlimited spindle hours

- Left spindle: 10" with 5,000 rpm and 843 Nm, or 12" with 3,000 rpm and 1,273 Nm optional

- Right spindle (optional): from 6" with 7,000 rpm and 95 Nm up to 10" with 5,000 rpm and max. 577 Nm

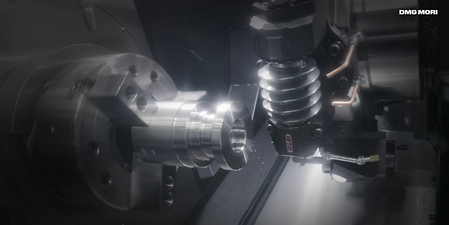

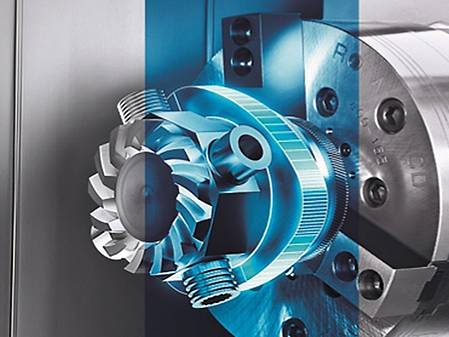

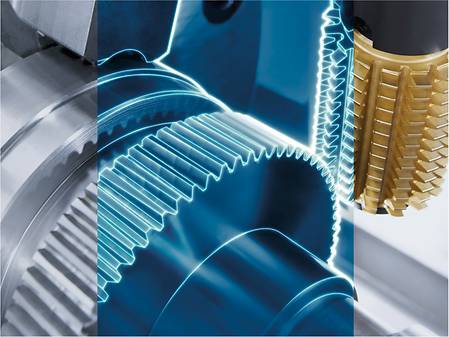

Highest milling performance

- BMT turret up to 12,000 rpm or 100 Nm and up to 20 tool stations (VDI = 12 stations)

- High-Speed up to 12,000 rpm and 86 Nm

- High-Torque up to 6,000 rpm and 100 Nm

GREENMODE for reduced energy consumption

- 16% less energy*, 44% less lubrication oil and 12% less compressed air consumption

- Machine with 400 V for up to 6% reduced energy consumption

- Environment-friendly coolant and mist solutions for extended coolant life and reduced energy consumption

(*This value is for NLX 2500 | 700)

Perfect fit for automation and series production

- Plug & Play automation interface and wide range of automation solutions, also retrofitable

- Stainless steel and ceramic coated covers for perfect chip flow

- Perfect chip, coolant & mist management with 900l zero-sludgeCOOLANT pro tank & easy to maintain zeroFOG

- Extended coolant life due to zero-sludgeCOOLANT pro with integrated sludge and oil collection system

- Universal self-cleaning chip conveyor system for reduced maintenance

Sample applications

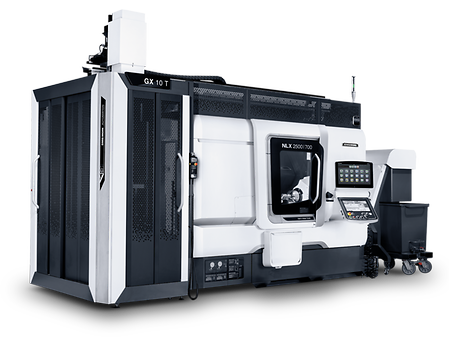

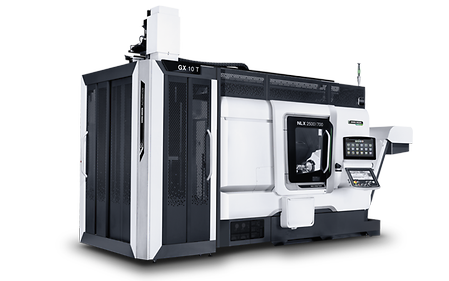

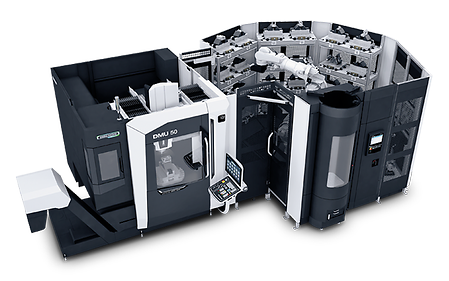

Automation

Open up the possibilities of automation

Increase productivity and quality, and operate 24/7. Our solutions offer extended machine uptime and support sustainability. Optimize your processes with our innovative automation solutions!

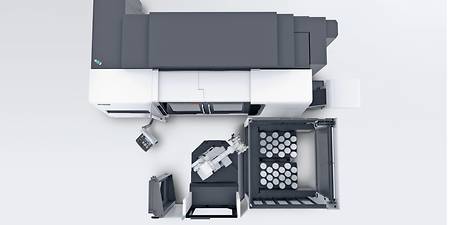

GX 3 / 5 / 7 / 15 // GX 5 / 10 T - Modular gantry loader system for one or more machines

- Highly productive and flexible workpiece handling for one machine or linking several machines

- GX 10 T: Handling of workpieces up to ø 200 x 150 mm and and weighing up to 10 kg

- Combinable with various kinds of automatic peripheral equipment (washing, measuring, marking, etc.) and grippers of flexible design available

- Easy programming and setup due to integration into the machine control

- Load status monitoring available via DMG MORI Messenger

Highlights GX 3 / GX 5 / GX 7 / GX 15 / GX 5 T / GX 10 T / GX 15 T

- Handling of workpieces up to ø 200 mm, a length of 150 mm and a weight up to 10 kg

- Compact, space saving with built-in loader

- Combinable with various kinds of automatic peripheral equipment (washing, measuring, marking etc.) and grippers available by flexible design

- Easy programming and setup due to integration into the machine control

- Loader status monitoring available via DMG MORI Messenger

- Easily expandable for two or more machines

- Optional up to 100 kg handling weight available

Flexible workpiece handling for small to medium batch sizes

- One app for uniform control of all Robo2Go variants, setting up a new workpiece < 5 minutes

- Robo2Go Turning, robot payload 12, 25 or 35 kg

- Rapid changeover from chuck to shaft parts

- Robo2Go Vision, robot payload 35 kg

- Robust 3D camera recognition, ideal for multi-job function

- Integrated in the machine control operation via CELOS APP: No need to change your NC programs!

- Intuitive usability thanks to dialog-guided software

- Creation of the process through predefined program modules via drag & drop: No robot programming knowledge necessary

- Setting up a new workpiece < 5 minutes

- Rapid changeover from chuck to shaft part storage

- Handling of shafts ø 20 – 170 mm and chuck parts ø 20 – 175 mm

- Three versions for all requirements: Robot payload 12 / 25 / 35 kg

- Stacking magazine

The storage expantion for your Robo2Go Turning

- 300 % higher capacity compared to standard

- Main time-parallel setup of the workpiece storage

- Multijob per drawer and within a drawer possible in the standard system

- Job management of all jobs via the Robo2Go Jobs app

- Robust 3D camera recognition, ideal for multijob function

- Infeed and outfeed of raw and finished parts by pallet

- Cylindrical chuck parts of ø 25 – 175 mm

Flexible workpiece handling for small to medium batch sizes

- One app for uniform control of all Robo2Go variants, setting up a new workpiece < 5 minutes

- Robo2Go Turning, robot payload 25, 35 or 70 kg

- Best-in-class layouts with left and right setup variants

- Vision Comfort Function 2.0: Intelligent 3D camera detection

- +12% capacity thanks to standard Euro pallets

- 32% higher capacity of the drawer storage

- Now with 50% more capacity: the pallet station with three Euro pallets

- Left-hand configuration as the optimal layout for turret lathes such as CTX & NLX

- Right-hand installation option for full accessibility to the control panel and tool magazine on Turn&Mill machines such as CLX TC, CTX TC & NTX

- Integrated in the machine control operation via Robo2Go APP: No need to change your NC programs!

- Job management of all jobs via the Robo2Go Jobs app

- Creation of the process through predefined program modules via drag & drop: No robot programming knowledge necessary

- 300 % higher capacity compared to standard

- Main time-parallel setup of the workpiece storage

- Multijob per drawer and within a drawer possible in the standard system

Flexible workpiece handling up to 115 kg

- One app for uniform control of all Robo2Go variants, setting up a new workpiece < 5 minutes

- Strongest version for 210 kg payload and 115 kg workpiece weight

- Handling of workpieces ø 40 to ø 400 mm as standard

- Fast supply and removal of raw material and finished parts using pallets or workpiece trolleys

- Free access to control and tool magazine

- Integrated in the machine control operation via CELOS APP: No need to change your NC programs!

- Intuitive usability thanks to dialog-guided software

- Creation of the process through predefined program modules via drag & drop: No robot programming knowledge necessary

- Setting up a new workpiece < 5 minutes

- Strongest version for 210 kg payload and 115 kg workpiece weight

- Handling of workpieces ø 40 to ø 400 mm as standard

- Fast infeed and outfeed of part-machined and finished parts by means of pallet or workpiece trolley

Holistic automation on the shop floor

- Collaborative automation solution with free layout design

- Omnidirectional movement for minimal space requirements (turning radius 0m)

- Basis for additional tasks, e.g. B. tool handling, chip disposal, etc.

- Material transport from Euro pallets 1,200 x 800 mm

- Maximum transport weight of up to 2,000 kg

- Security based on Sick and Siemens technology

- Autonomous transport of material pallets

- Transport of different load carriers

- Integration into DMG MORI automation systems for workpiece handling – exchange of finished part and raw part pallets

- Integration into existing processes

- Scalable and expandable at a later date

- Autonomous transport of chip containers

- Automatic transport order from the master computer

- Extended autonomy of the machine tool

- Material and chip transport can be combined

- Tool identification in the standard

- Autonomous transport and exchange of tools between machines and tool storage systems

- Max. tool dimensions ø 280 / 400 mm

- Max. tool weight 30 kg

- Transport weight 720 kg (24× 30 kg)

- Maximum number of tools: 24 pcs

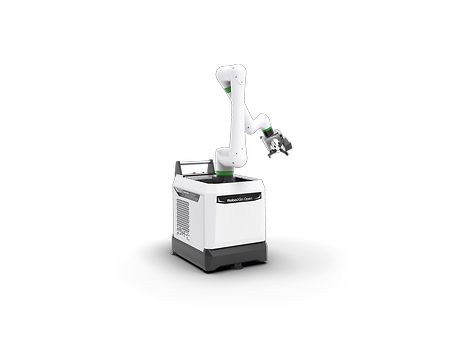

Highly flexible and collaborative automation for workpieces up to 10 kg

- Freely movable workpiece handling, incl. robot and storage area on a trolley

- Workpieces up to 10 kg, or 5 kg x 2 with double gripper

- No infrastructure changes

- No safety fence necessary

- 600 × 900 mm footprint

- Collaborative robots, setup time <5 minutes*

- Direct teaching without robot knowledge

- Easy connection via Ethernet

- Two types of workpiece stockers can be selected

- Storage for up to 64 workpieces

- Blow-off device

- Regrip station

*When the optional tag position correction function is selected and when the machine / workpiece setup is already completed.

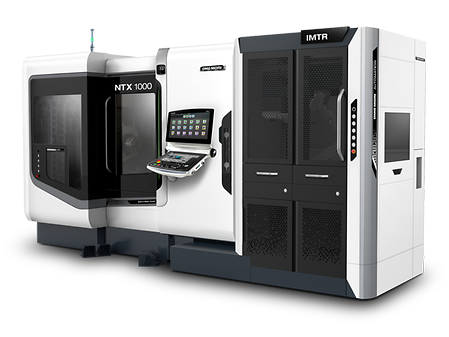

The perfect robotic automation for the NTX

- Loading and unloading by robot

- NTX 500

- Robot max. transfer weight: 7 kg(reference max. weight of workpiece per hand: 2 kg)

- max. workpiece diameter: Φ70 mm

- max. workpiece length: 65 mm

- NTX 1000

- Robot max. transfer weight: 12 kg (FANUC), 10 kg (KUKA) (reference max. weight of workpiece per hand: 2 kg)

- max. workpiece diameter: Φ70 mm

- max. workpiece length: 100 mm

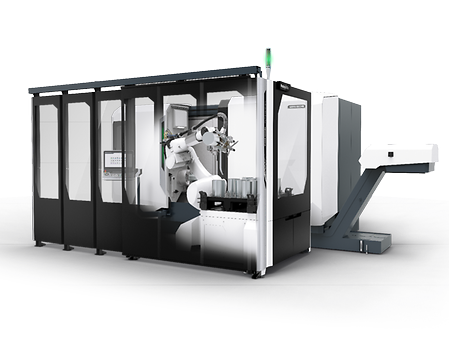

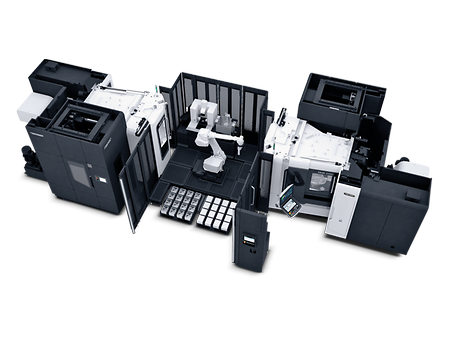

Flexible modular robot system for ≥ 1 machine

- Modular concept with standardized peripheral devices, e. g. washing, measuring or marking

- 80 % shorter setup time due to modular and standardized peripherals and robot programs

- Flexible adaptation to system changes including after installation

- Simple and easy operation via the MATRIS control system without programming

- Handling of workpieces up to ø 200 × 200 mm, 1 × 20 kg or 2 × 10 kg

- Stacking magazine:

- 14, 20 and 26 pallets: ø 150 × 120 mm, max. 35 kg per pallet

- 10 and 20 pallets: ø 200 × 200 mm, max. 75 kg per pallet

- Loading of oversized tooling in case of vertical machining center

- Available for 13 series, e. g. NLX, NTX, NHX, DMU, NMV, eVo, etc.

- Ideal for the flexible production of 50 to 200 workpieces / day

- Space-saving pallet handling for up to 40 pallets

- 400 × 400 mm pallet size

- 150 kg transfer weight (workpiece and pallet)

- Integration of secondary processes such as deburring or marking possible

- Available for the CMX 50 U, CMX 70 U, DMU 50, DMU 65 monoBLOCK, CMX 600 V, CMX 800 V, CMX 1100 V

Workpiece automation with maximum flexibility thanks to flexible layout design

- Modular concept with flexible layout design

- Driverless transport systems without guide rails or tracks

- Collaborative: human and machine in one system

- Vision sensor enables robot arm positioning accuracy better than ± 1 mm

- Workpieces up to ø 150 × 120 mm and 10 kg

- Compact design (700 × 1,035 mm)

- Laser sensor

- Excellent operational performance and stability, including on an uneven floor

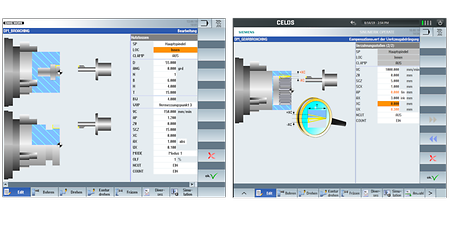

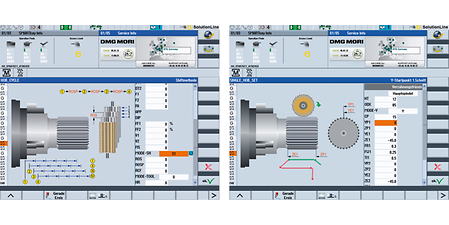

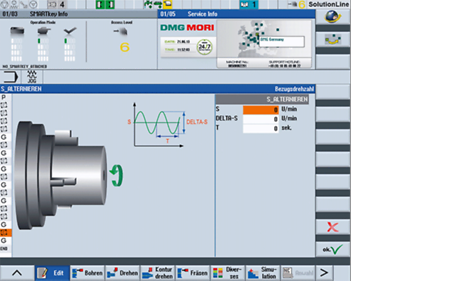

Control & software

Experience the speed of digital transformation (DX)

Revolutionize your operations, unlock new opportunities, drive efficiency and sustainability by reducing power consumption – while gaining a powerful competitive advantage.

- Machining also on machines without Y-axis

- Highly productive without milling the individual surfaces

- Dialog-guided programming thanks to the technology cycle

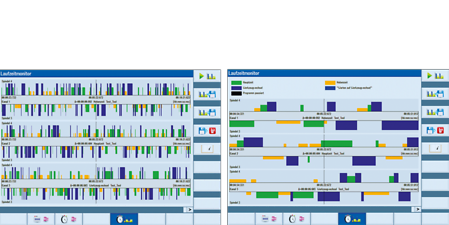

- Application especially for multi-channel machines for time analysis of the production process and as a basis for the cycle time optimization

- Individual zoom in to view minute details for cycle time optimization

- Histogram up to three channels

- Provides the basis for cycle time optimization by graphical inputs

- Save / Load the recorded data to compare individual optimized steps

- In combination with the Gildemeister structure programming, A safe and fast reboot of the machining program after an interruption

- Easy program operation especially with multiple spindles or tool magazine

- Displays the process status of the workpiece

- Display of the detailed status on the controller

- Enter remarks automatically by the GILDEMEISTER structure programming.

- Safe re-entry into the program by the press of a button instead of searching for a specific block.

- Structured approach with more than 20 standard programs and more than 200 processing variants incl. automation (bar processing, robot / portal loading, ...)

- Display of the program status with additional markers (EPS) for the sub-programs.

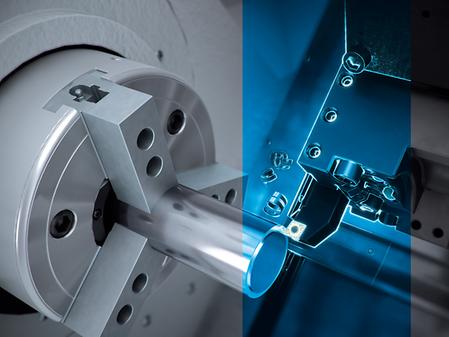

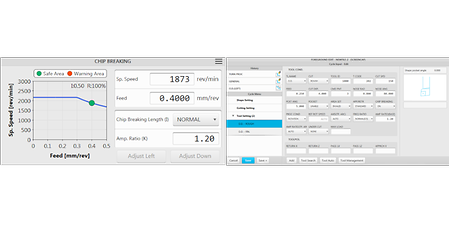

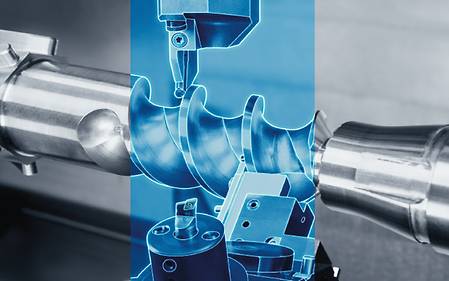

- Oscillating movement of the feed axis results in air cutting, which leads to effective chip size reduction

- For external longitudinal turning of internal and external diameters, facing, drilling and grooving*

- Integrated safety function checks the plausibility of parameter entries

* For inclined surfaces, a step pattern results because the feed can only be oscillated in one axis at a time.

- The chip length can be practically determined by the cycle and is independent of the material

- No more process interruptions, as chip balls are avoided

- Easy setting on the HMI with high operating safety

- Easy handling of non-circular parts

- Intuitive user interface for polygons / oval turning

- Making the required geometries with possibilities of simple fine-tuning

- Possiblity of fine tuning of the geometric parameters (long / short Semi-axis and bearing angle)

- Machining can be combined with main spindle or counter spindle

- NEW: On-Point Threading - Position oriented thread production

- Free definition of contours, pitches and gears possible

- Creation of large transmission threads, which can not be manufactured by simple thread chasing

- Trapezoidal, buttress and knuckle thread easily programmable at the machine

- Screw conveyor with any profile geometry

- Ball screw nut with cross holes simple to realize

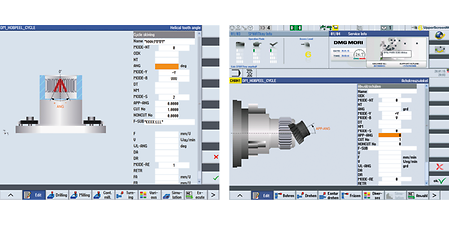

Highlights

- Producing profiles with undercut due to the profile splitting option.

- Applying standard tools and tool holder for left and right sided machining of the flanks

- Surface quality of Ra 0,3 an CrNi-Alloys possible

- Structured input parameters for the groove geometry, the tool and the machining strategy

- Inner and outer grooves in any position and number freely adjustable

- Easy compensation of tool displacement + Calculation of residual strokes based on selected machining strategy

- High flexibility in the production of any groove geometries with standard tools on standard machines

- Reliable alternative when pushing with driven tools is no longer an economical or technological solution

- Advantages of rigid machine guidance for better groove quality

- Higher stability due to optimal force transmission in thelongitudinal direction of the tool holder

- Generation of tool feed in the Y-direction for parting off components at a push of a button

- Compatible with the standard cycle CYCLE92 (Part off cycle), so that the operator can program as usual (ShopTurn and DIN / ISO)

- Up to three times higher productivity possible (3x feed) with simultaneously improved chip control

- Reduced noise level and higher surface quality through more tool stability

- Less material loss due to reduction of the parting width

- Superposition of the turning movement by additional X- and Y-traverses

- Applicable for turning and milling

- Eccentric geometries easy to manufacture

- Exact axis coupling and synchronization in the background

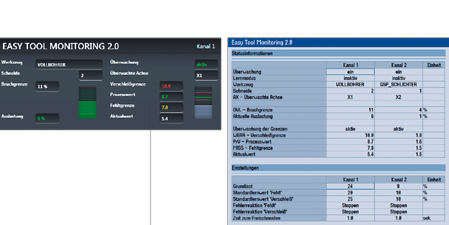

- Solutions for a safe process and for the efficient use of important machining steps

- Applications: cone cleaning, tool data monitoring, safe withdrawal movement, tapping, deep hole drilling, external thread and spigot milling, internal thread and circular milling, reverse countersink cycle

- 12 stored machining strategies for stock removal, deep hole drilling, Pocket milling machines*

- Runtime optimization according to individual application

- Safe retraction after program break

- Tool data monitoring

- Prevention of damage due to tool breakage or tool overload

- Sensorless with automated learning of load limits

- For turning, milling and drilling (up to 3 mm diameter)

- NEW: User interface on CELOS SideScreen

- NEW: Powerful algorithm for efficient monitoring after the first workpiece

- Protection Package: Perfect supplement to MPC Lathes. Price advantage (approx. 40%)

- Save the monitoring limits for each tool and every cutting edge in the program

- By pushing the associated key the X- axis and the Y-axis travel to the positive end-positions for external machining

- Ideally suited to prepare the work space for set-up and alternatively also as an emergency rescue function.

- Easy operation when setting up multi - channel machinery

- Possibilty of a fast response during external machining as a rescue function

- Automatic optimization of servo drives parameters for Main- and Sub-Spindle

- Reduction of Setup time

- Optimization of machining result

- Setup Time reduction

- Automatic determination of parameters independent from machine operator experience

- saving the setting in NC-program for more quality assurancet

- Programming of the gearing parameters via dialog input

- For spur gear, helical gear and worm gear

- Gear cutters and disk cutters can be used

- Maximized tool life by shifting of the cutter

- Achievable quality ≤ DIN 7

- Gear profile modifications easy to handle

- Use of regrinded tools

- Error prevention by monitoring (e. g. wrong axis cross angle, or wrong turning speed, or turning direction)

- Easy to operate through three parameters and without additional sensors

- Avoiding vibrations by means adaptation of the speed

- Application for the main spindle and counter spindle, or for milling machines with FD tables with Direct Drive

- No manual intervention by the operator

- Identical repeatability for all components

- Increased process safety for special applications by avoiding vibrations. example, When using long thin drills or for milling parts with critical clamping

- Straight and helical external or internal spur gears and splines

- Arrow teeth with tooth offset Turn-mill machines

- Ball-shaped toothing by mathematical transformation of the 6th virtual axis

- Productive complete processing

- Cost-effective gear cutting on standard machine with standard tools

- Flexible for different gear geometries

- Quality inspection in the process

- Program creation based on blank drawings and gear data

- Optimization of workpiece orientation e.g. after heat treatment

- Interface for coordinate measuring device (Klingenberg, Leitz, Zeiss)

Service & training

Comprehensive carefree service and training for your production

Take advantage of our full-service offering and hands-on training to maximize machine performance and minimize downtime. With comprehensive maintenance packages, original spare parts and customized training programs, we will take your production and your team to the next level.

Downloads & Technical Data

Special technical articles, analyses, and background information on topics that move our industry.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Get access to many useful digital functions and services and have all important data at a glance. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Unlock access to your Share Hub and many other functions and services. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

For general enquiries, please use our contact form.

For service and spare parts enquiries please use the my DMG MORI portal: https://us.mydmgmori.com/

Thank you very much for your interest in our products.

To download our brochures please fill in the form below.

If you accept the storage of cookies, this form appears only once during your visit.