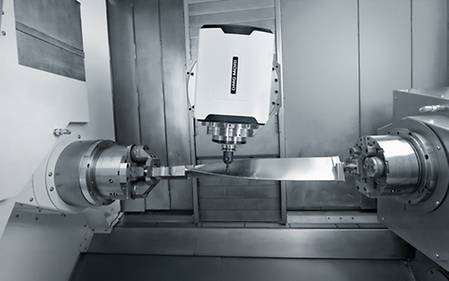

Maximum Productivity with Turn & Mill Machines

Where universal lathes reach their limits, Turn & Mill machines have the capacity to go further. They combine turning and 5-axis milling as well as simultaneous milling with five axes in a single workspace. Thanks to 6-sided complete machining, a Turn & Mill machine – a combination machine so to speak – achieves challenging geometries in one pass. In other words: Where, in the past, different machine tools carried out several process steps in metalworking; today, only one Turn & Mill machine is required. This eliminates set-up times, while throughput times decrease and – since manual re-stressing processes are omitted – the production quality increases.

Turn-milling for all requirements

With the CLX 450 TC, DMG MORI offers an attractive entry point into turn-milling technology. The CTX beta TC and CTX gamma TC, as well as the NT and NTX series, also serve a wide range of applications – from the production of precise small parts to XXL machining of workpieces up to Ø 1,070 x 6,076 mm. On the one hand, the portfolio thrives on the decades of experience with which DMG MORI consistently develops the machines. On the other hand, this continuous development results in high-quality components and innovative equipment options with modern controls. These include, in particular, the stable B-axis in conjunction with the space-saving compactMASTER Turn & Mill spindles, such as tool magazines for up to 180 tools, or the second tool carrier as a lower turret.

Key Highlights:

- Advantageous entry into turn-milling

- Wide range of models for a wide range of applications

- High-quality components for quality-oriented production

- Innovative equipment options for maximum productivity

Overview

Wide-ranging Turn & Mill portfolio

CLX 450 TC: Entry point into turn-milling

With the CLX 450 TC, DMG MORI meets the increasing production requirements for smaller quantities and greater variety of parts. A B-axis with compactMASTER turn-milling spindle replaces the traditional tool turret. Also on board are an automatic tool changer with tool magazine, the usual powerful main spindle and tailstock or an optional counter spindle. This makes the CLX 450 TC the perfect entry point into 6-sided complete machining.

CTX TC: Variety of machining in any size

The CTX beta TC and the CTX gamma TC for longer workpieces with larger diameters have been setting standards in turn-milling for many years. As DMG MORI has successively expanded the series, today there is an extensive portfolio for components with a length of up to 3,000 mm. The compactMASTER Turn & Mill spindle ensures sufficient space in the workspace. A modular construction kit also offers individual equipment options such as a counter spindle, a tailstock or a second turret. Comprehensive cooling measures for high temperature stability and direct distance measuring systems from Magnescale ensure maximum precision.

NTX: Turn & Mill complete machining with highest rigidity

DMG MORI has developed the NTX 1000 as a compact Turn & Mill machine for tightly dimensioned production areas, for example, in medical technology. The success of the space-saving miracle quickly led to the expansion of the series. Today, five models are available – from the even more compact NTX 5000 to the NTX 3000, which efficiently processes even large drive shafts with a workpiece length of over 3,000 mm. The highly rigid construction of NTX models and roller guides ensure high rigidity in the machining of precision components.

NT: Highest precision in many industrial sectors

The NT series stands for fast and high-precision machining due to its box-in-box structure and having the drive in the center of gravity. The octagonal frame construction allows for optimal heat regulation and excellent damping properties, permitting a precise feed at high speed. With sizes ranging from just under 1,600 mm to over 6,000 mm in workpiece length, the NT series covers a wide range of applications in a wide variety of industrial sectors.

Automation

DMG MORI gives its Turn & Mill machines additional productivity with integrated automation solutions. The range runs from bar loaders and integrated robots for automatic workpiece removal to gantry loaders and flexible robot applications for autonomous loading and unloading. These include the Robo2Go models, the MATRIS Light and the IMTR. The automation of turn-milling is a profitable component to long-term global competitiveness.

Turn-milling: the most important things to know, in brief

What is a Turn & Mill machine?

Turn & Mill machines combine turning and milling in a single workspace. This means that both technologies can be implemented 100 percent. Like lathes, they have a main spindle that sets the workpiece in rotation. If the geometry requires milling operations, an additional milling spindle with a B-axis is used on the Y-axis, which can machine the workpiece 5-axis in the same clamping – with the same variety of tools as a milling machine.

What added value does turn-milling offer?

The combination of turning, 5-axis (simultaneous) milling and 6-sided machining in one workspace means that complex workpieces can be finished in one pass. Since no further CNC machine tools are required, setup times are eliminated, which speeds up the overall process. At the same time, the missing re-stressing processes increase component quality.

For which applications is turn-milling ideally suited?

Wherever challenging workpieces are produced, Turn & Mill machines can be used to the greatest advantage Implants in medical technology and turbine blades in the aerospace industry are just as much a part of this as chassis components in automotive engineering or large crankshafts in shipbuilding.