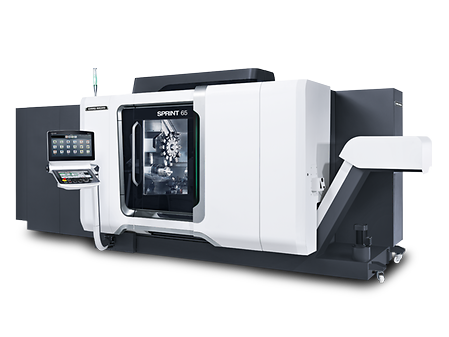

SPRINT 65

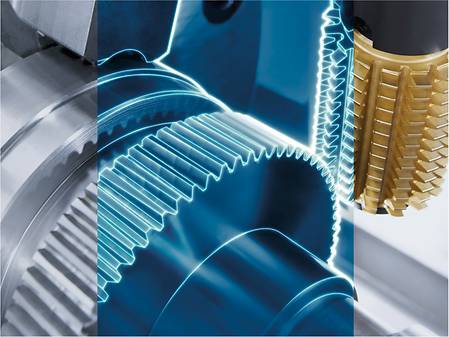

4-axis production turning with 3 Y-axes, B-axis and 3 turrets for up to 36 driven tools for max diameter 3.7 in.

Max. workpiece diameter

175 mm

6.9 in.

Max. workpiece length

420 mm

16.5 in.

Max. bar diameter

65 mm

2.6 in.

Max. X-axis travel

165 mm

6.5 in.

Max. Y-axis travel

80 mm

3.1 in.

Max. Z-axis travel

420 mm

16.5 in.

Control & software alternatives

SIEMENS

Fanuc

Highlights

Automatic turning with both collet and chuck application

- Main spindle with 5,000 rpm, 110.6 ft lb., 29.5 hp (nominal)

- Counter spindle with 5,000 rpm, 63.4 ft lb, 24.1 hp (nominal)

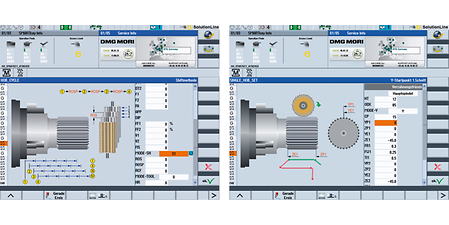

- SIEMENS models are 2 turrets twin concept, 3 turrets, and 3 turrets plus B-axis

- FANUC model is 3 turrets

Up to 36 tool stations

- Total of 12 VDI 30 tool stations with Trifix per turret, each can be driven.

- Driven tools spindles up to 12,000 rpm, 8.9 ft lb, 8.7 hp (nominal)

- B-axis with torque motor and direct measuring system

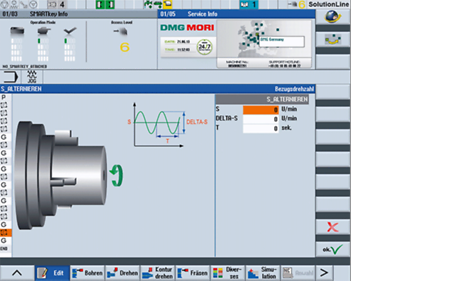

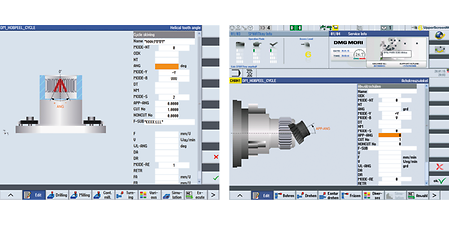

FANUC and SIEMENS ERGOline Full-HD touchscreen 21,5” with CELOS

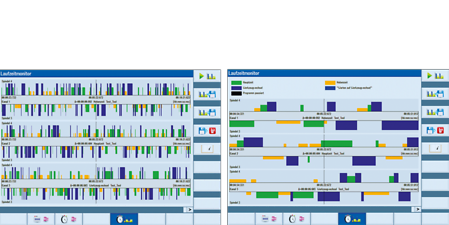

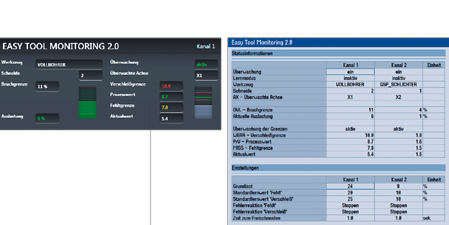

- CELOS APPs facilitate the consistent management, documentation and visualization of order, process and machine data

- Up to 10 linear axes, 1 B-axis and 2 C-axes

- Fanuc version with MAPPS V

Highly dynamic drivers in all axes for fast machining and minimal idle time

- 100% production optimized design

- Free chip fall due to vertical machine bed, no temperature influence

- Thermostable and self rigid machine bed with 3-point-support

- Machining of longer workpieces with two turrets and the patented TWIN design

- Highest accuracy due to water-cooled main and counter spindle

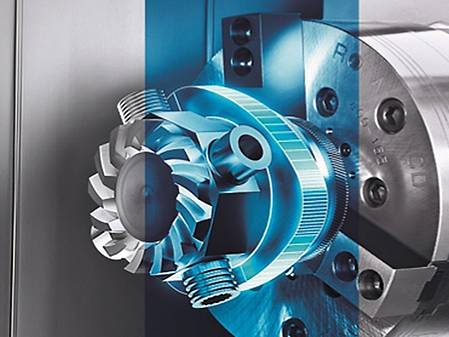

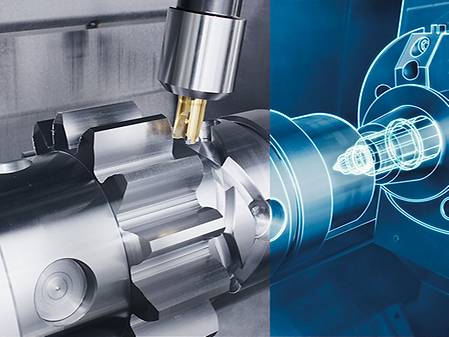

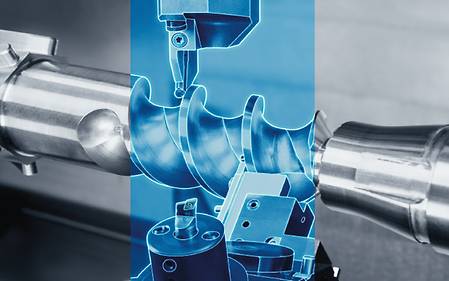

Sample applications

Control & software

Experience the speed of digital transformation (DX)

Revolutionize your operations, unlock new opportunities, drive efficiency and sustainability by reducing power consumption – while gaining a powerful competitive advantage.

CELOS

Integrated digitization of the DMG MORI machines & the shop floor:

- CELOS Machine: APP-based user interface with access to all production-related information

- CELOS Manufacturing: 27 CELOS APPs for the optimal preparation & processing of orders

- Digital Factory: Continuous digital workflows from planning to production & service