ULTRASONIC 80 eVo linear

Universal ULTRASONIC Machining Centre

Highlights

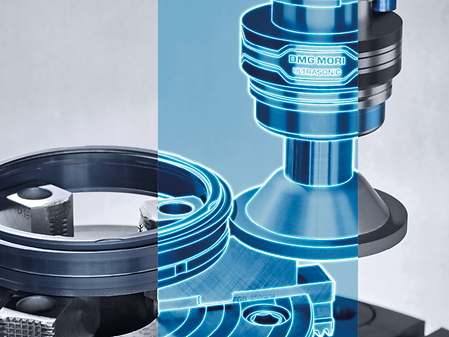

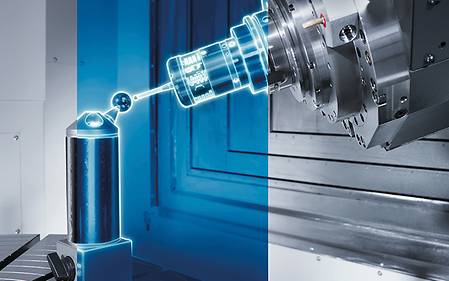

ULTRASONIC technology integration - reduced process forces for higher productivity

- Technology integration via HSK-A63 / HSK-A100 interface for ultrasonic superimposition of the tool rotation with amplitudes up to 15 µm

- Process forces reduced by up to 50% through ULTRASONIC enable, depending on requirements: higher feed rates, improved surface quality up to Ra <0.1 µm, longer tool life

- Specific coolant treatment systems with centrifuges, optimized for the ULTRASONIC processing of Advanced Materials

ULTRASONIC 3rd Generation - Optimal process control through intelligent controls

- Constant amplitude in the process to ensure reproducibility

- Automatic detection of the working frequency, significantly improved hardware for signal acquisition

- Frequency tracking and simultaneous power control in real time for optimal process stability

- Ensuring the ULTRASONIC advantages even with non-optimal tools

- Fully compatible with 2nd generation ULTRASONIC actuator

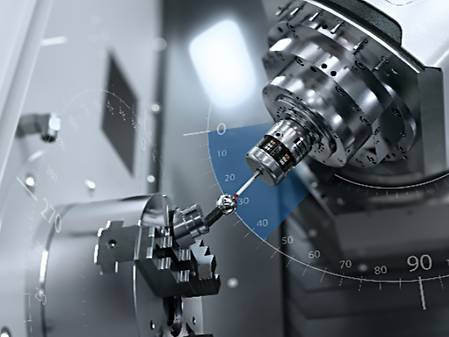

5-Axes Simultaneous Machining with proven Swivel Rotary Table

- Swivel range of the B-axis -5/ +110°

- Table load up to 600 kg

- Cooling of table unit table bearings and drives

Mill-Turn Operation

- Speed of the C-axis up to bis 1,200 rpm

- Motorspindle with 18,000 rpm, 130 Nm and HSK A63

Spindles

- speedMASTER 20,000 rpm in standard version

- speedMASTER 15,000 rpm with 200 Nm (option)

- Motorspindle 24,000 rpm (option)

Sample applications

Automation

Standard automation and customized solutions in VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customized automation solution for flexible manufacturing systems:

Universal pallet handling from DMG MORI

- Control directly via the machine control system

- High variability of available configurations from 24 round pallets of ø 148 to four 500 × 500 mm pallets

- Up to 150 kg workpiece weight as standard (optionally expandable to 250 kg)

- Possibility to prioritize orders

- EROWA clamping system as standard, SCHUNK optional

- High clamping repeatability (< 0.002 mm for the chuck EROWA UPC-P)

- Optimal accessibility to the machine and automation

PH Cell 300 - Modular pallet handling for up to 40 pallets

- Modular automation concept with up to 40 storage locations in a 10.7 m2 footprint

- Handling of different pallet sizes in one system

- Up to 300 kg transfer weight (workpiece incl. pallet)

- Separate setup station for ergonomic and simultaneous loading and unloading of pallets

- Convenient and simple control of the automation directly via the machine control panel

Holistic automation on the shop floor

- Collaborative automation solution with free layout design

- Omnidirectional movement for minimal space requirements (turning radius 0m)

- Basis for additional tasks, e.g. B. tool handling, chip disposal, etc.

- Material transport from Euro pallets 1,200 x 800 mm

- Maximum transport weight of up to 2,000 kg

- Security based on Sick and Siemens technology

- Autonomous transport of material pallets

- Transport of different load carriers

- Integration into DMG MORI automation systems for workpiece handling – exchange of finished part and raw part pallets

- Integration into existing processes

- Scalable and expandable at a later date

- Autonomous transport of chip containers

- Automatic transport order from the master computer

- Extended autonomy of the machine tool

- Material and chip transport can be combined

- Tool identification in the standard

- Autonomous transport and exchange of tools between machines and tool storage systems

- Max. tool dimensions ø 280 / 400 mm

- Max. tool weight 30 kg

- Transport weight 720 kg (24× 30 kg)

- Maximum number of tools: 24 pcs

Flexible workpiece handling for small to medium batch sizes

- One app for uniform control of all Robo2Go variants, setting up a new workpiece < 5 minutes

- Robo2Go Milling, robot payload 25, 35 or 70 kg

- Best-in-class layouts with right setup variant

- +12% capacity thanks to standard Euro pallets

- 32% higher capacity of the drawer storage

- Now with 50% more capacity: the pallet station with three Euro pallets

- Right-hand installation option for full accessibility to the working area, control panel and tool magazine

- Integrated in the machine control operation via Robo2Go APP: No need to change your NC programs!

- Job management of all jobs via the Robo2Go Jobs app

- Creation of the process through predefined program modules via drag & drop: No robot programming knowledge necessary

- 300 % higher capacity compared to standard

- Main time-parallel setup of the workpiece storage

- Multijob per drawer and within a drawer possible in the standard system

Pallet automation with maximum flexibility through free layout design

- Modular concept with flexible layout design

- Driverless transport systems without guide rails or tracks

- Collaborative: Man and machine in one system

- Navigation through natural navigation

- Pallet sizes from 500 × 500 mm to 1,600 × 1,250 mm

- Workpieces up to 5,000 kg and ø 1,600 mm

Free accessibility

- Best visibility into the workspace at any time

- Manual or crane loading still possible

- Collaborative system – man and machine in one system

Modular concept with free layout design

- No safety housing for the automation system necessary

- Free positioning possibility of the individual modules

- Subsequent integration into existing production

Simple expansion of automation system

- Additional shelf modules to increase the number of storage places

- Additional AMRs can be integrated in the system

- Machines with an automation interface can be integrated very quickly afterwards

Minimum space requirement

- Free pallet handling system without fixed installation requirements on hall floor

- AMR paths remain walkable and passable

- Laser scanners guarantee personal protection in driving direction

- Omnidirectional movement for minimum space requirements (turning circle 0m)

- Flexible automation concept - Automation of different machine types with one system

Control & software

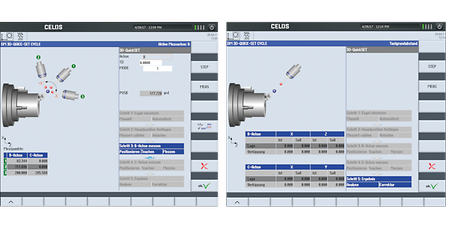

CELOS

Integrated digitization of the DMG MORI machines & the shop floor:

- CELOS Machine: APP-based user interface with access to all production-related information

- CELOS Manufacturing: 27 CELOS APPs for the optimal preparation & processing of orders

- Digital Factory: Continuous digital workflows from planning to production & service

- With ULTRASONIC 3rd Generation and 32.000 rpm for micro drilling with highest process safety

- Fully integrated regulation of the drilling force in the preset- spindle down to smaller 1 N – independent from the z-axis of the machine

- ICS with seperate fine filtration and flow rate control starting from 1 l/min

- Automatic ejector mechanism for drill cores from the diamond hollow drills

- Automatic reaction of process changes (materials, tool abrasion) by adapting the feed rate in the process

- Directly evaluates the signals (frequency and power) of the ULTRASONIC system

- Optionally also takes the spindle utilization into account

- Always optimal process performance

- Process control through predefined parameter windows

- Safety for fragile workpieces made of brittle-hard materials

- Automatic detection of contact with the workpiece

- Tool breakage detection without additional measuring device

- Self-learning algorithm for precise contact detection

- Precise drilling depth independent of tool wear

- Time saving due to automatic recognition of the workpiece contact

- Increased process reliability due to closed control loop

- Grinding of rotationally symmetrical structures in hard-brittle materials with highest performance

- Manufacturing of bearing rings, wafer chucks, microwave windows for many areas of the semiconductor industry, optics and technical ceramics

- Use for various contours, also spheres

- Easy programming through intuitive operator masks

- Selection of different cutting edges and angle of the grinding tool

- Automatic adjustment of the tool contact point depending on the contour

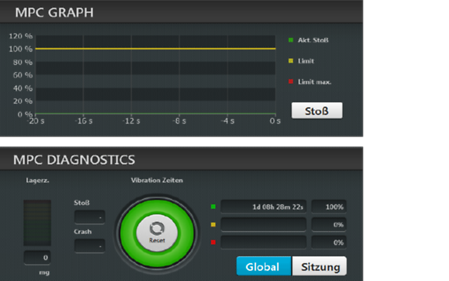

- Vibration monitoring in the process

- Rapid shutdown in case of a crash

- Manual retraction even in swiveled machining plane

- NEW: Torque monitoring

- New: Recommended with Protection Package for CTX TC machines

- Avoiding tool breakage

- Increase in machine availability

- Damage reduction

Turning

- Measurement and correction of the position of turning and Pivot axes (C4, C3, B)

- Sag compensation possible

- Can be used in combination with standard probes from customers (recommended Renishaw, Blum)

Milling

- Toolkit for checking and correcting the kinematic accuracy of 4- and 5-axis machine configuration

- All head variations and table axes

- Reliable re-calibration of the machine before a highly precise processing

- Continuous documentation of machine accuracy

- No rejected parts due to unknown Geometric-deviations

- Periodic recalibration of the machine with comprehensive documentation

- Highest kinematic accuracy in self-regulation

Service & training

Downloads & Technical Data

Special technical articles, analyses, and background information on topics that move our industry.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Get access to many useful digital functions and services and have all important data at a glance. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Unlock access to your Share Hub and many other functions and services. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

For general enquiries, please use our contact form.

For service and spare parts enquiries please use the my DMG MORI portal: https://us.mydmgmori.com/

Thank you very much for your interest in our products.

To download our brochures please fill in the form below.

If you accept the storage of cookies, this form appears only once during your visit.