ULTRASONIC 210 P

Max. X-axis travel

2100 mm

82.7 in.

Max. Y-axis travel

2100 mm

82.7 in.

Max. Z-axis travel

1250 mm

49.2 in.

Max. workpiece length

3200 mm

126 in.

Max. workpiece width

2500 mm

98.4 in.

Max. workpiece height

1460 mm

57.5 in.

Max. workpiece weight

8000 kg

17637 lbs.

Control & software alternatives

SIEMENS

Highlights

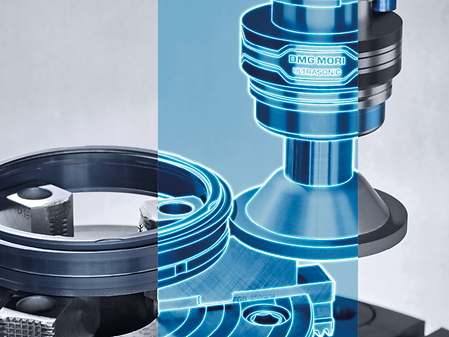

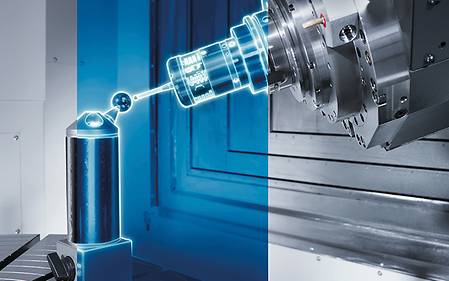

ULTRASONIC technology integration for an expanded machining portfolio

- Technology integration via HSK-A63 / HSK-A100 / HSK-E50 actuator system

- ULTRASONIC superimposition of the tool rotation with amplitudes up to > 0.254 µin.

- Automatic frequency detection -adaption, amplitude regulation and automatic feed adjustment

- Up to 50% reduced process forces due to ULTRASONIC allow: higher feeds, better surface finishes up to Ra < 0.00254 µin. and longer tool life.

Precision

- Maximum accuracy through water-cooled feed drive

- Band filter unit with 980 l as standard

- Highest long-term accuracy due to cooled linear guideways and active spindle growth control.

Performance

- High dynamics with feed speed up to 2,362.2 ipm

- Also available in mill- /turn - version

- High feed power up to 8,992.4 lbf

- Biggest spindle range in the market: powerMASTER motor spindle with up to 737.6 ft lb and torqueMASTER gear spindle with 1,327.6 ft lb

Efficiency

- Lower energy consumption through intelligent needs-based power units.

- Gantry design with vertically moving cross beam with hydraulic weight compensation.

- Fast innovative wheel type magazine with up to 303 tools with minimized footprint.

Highest rigidity and dynamics up to 19.7 ft/s²

- Thermosymmetrical construction

- 3-point support with an inherently stiff machine bed, no foundation required

- High temperature stability standard with positioning accuracy down to 0.25 µin

- Position accuracy down to 0.20 µin with accuracy pack option

- Worldwide unique high precision varinat µPrecision with Position accuracy down to 0.10 µin

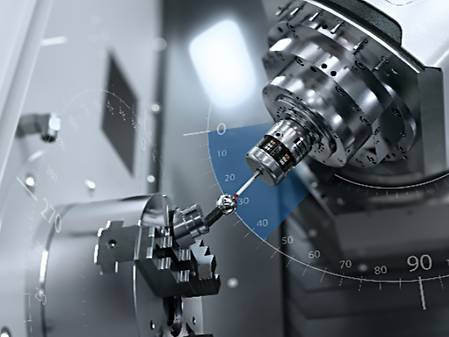

Sample applications

Control & software

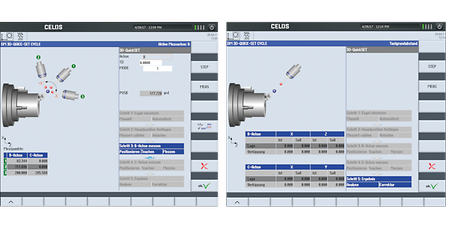

CELOS

Integrated digitization of the DMG MORI machines & the shop floor:

- CELOS Machine: APP-based user interface with access to all production-related information

- CELOS Manufacturing: 27 CELOS APPs for the optimal preparation & processing of orders

- Digital Factory: Continuous digital workflows from planning to production & service