ULTRASONIC 200 Gantry

5-axis ULTRASONIC machining in XXL

Max. X-axis travel

4000 mm

157.5 in.

Max. Y-axis travel

2000 mm

78.7 in.

Max. Z-axis travel

1200 mm

47.2 in.

Max. workpiece length

4300 mm

169.3 in.

Max. workpiece width

2000 mm

78.7 in.

Max. workpiece height

1250 mm

49.2 in.

Max. workpiece weight

20000 kg

44092.5 lbs.

Control & software alternatives

SIEMENS

Highlights

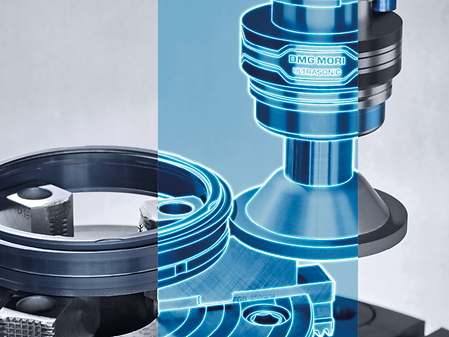

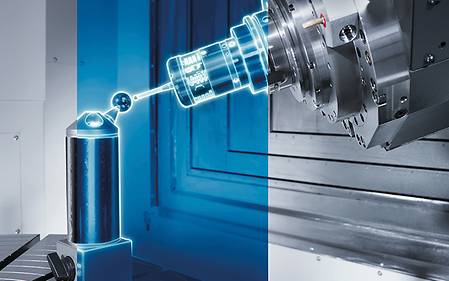

ULTRASONIC technology integration - reduced process forces for higher productivity

- Technology integration via HSK-A63 / HSK-A100 interface for ultrasonic superimposition of the tool rotation with amplitudes up to 15 µm

- Process forces reduced by up to 50% through ULTRASONIC enable, depending on requirements: higher feed rates, improved surface quality up to Ra <0.1 µm, longer tool life

- Specific coolant treatment systems with centrifuges, optimized for the ULTRASONIC processing of Advanced Materials

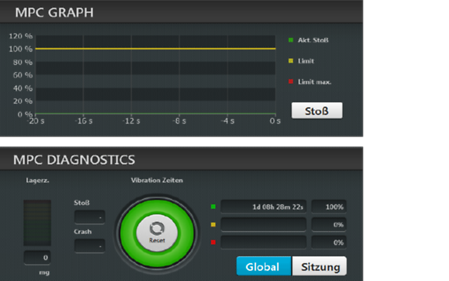

ULTRASONIC 3rd Generation - Optimal process control through intelligent controls

- Constant amplitude in the process to ensure reproducibility

- Automatic detection of the working frequency, significantly improved hardware for signal acquisition

- Frequency tracking and simultaneous power control in real time for optimal process stability

- Ensuring the ULTRASONIC advantages even with non-optimal tools

- Fully compatible with 2nd generation ULTRASONIC actuator

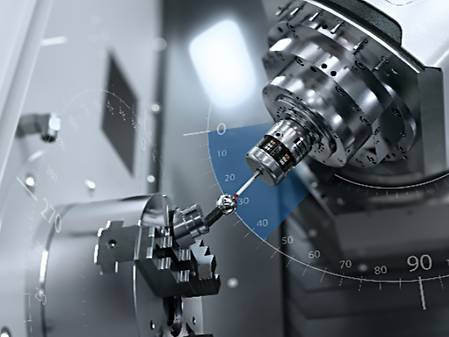

Flexibility through spindle versions

- Vertical spindle with 20,000 rpm

- 45° head and 90° head for 5-axes machining up to 30,000 rpm

- Ready for new technologies like Ultrasonic, Laser or machining of carbon material

Working area concept

- Fixed table 88.6 x 78.7 in with 22,046 lb loading capacity

- T-slots across the table for easy chip removal

- Chip conveyors on both sides of the table

Low Gantry Design

- 1,968.5 ipm (in/min) rapid traverse

- Best visibility into the working area due to missing side walls

- Maximum utilization of the working area

5-axes machining

- 45° head with 90° swivel range and +/- 300° rotating range

- compactMASTER spindle with 20,000 rpm

- 90° head with +/- 120° swivel range and +/- 300° rotating range

- compactMASTER spindle with 20,000 rpm up to 30,000 rpm

Sample applications

Control & software

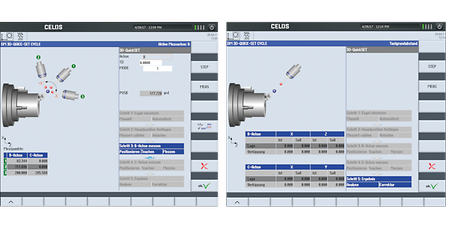

CELOS

Integrated digitization of the DMG MORI machines & the shop floor:

- CELOS Machine: APP-based user interface with access to all production-related information

- CELOS Manufacturing: 27 CELOS APPs for the optimal preparation & processing of orders

- Digital Factory: Continuous digital workflows from planning to production & service