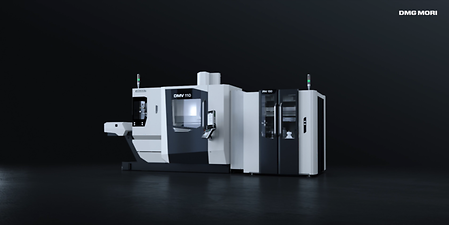

DMV 110

High performance & rigid vertical milling center with X-axis stroke 1100 mm for workpiece up to even 1700 kg!

Max. X-axis travel

1100 mm

43.3 in.

Max. Y-axis travel

600 mm

23.6 in.

Max. Z-axis travel

510 mm

20.1 in.

Max. workpiece height

550 mm

21.7 in.

Max. workpiece weight

1700 kg

3747.9 lbs.

Max. workpiece length

1400 mm

55.1 in.

Max. workpiece width

600 mm

23.6 in.

Control & software alternatives

SIEMENS

HEIDENHAIN

Highlights

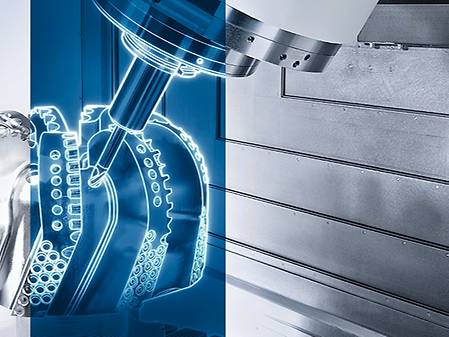

Outstanding rigidity

- Unique design based on monolithic machine bed and massive castings

- +40% higher static rigidity comparing to the predecessor

- Wide roller guideways in all axes

Fixed machine table for the best process stability

- Handling of workpiece even up to 1700 kg

- Constant dynamic characteristic regardless the workpiece weight

- Perfectly-suited for die&mold application

The highest performance

- Powerful spindle with BIG PLUS interface from inlineSPINDLE 12.000 rpm, through speedMASTER 15.000 rpm High Torque, ending at speedMASTER 20.000 rpm

- Rapid traverse 42 m /min in all linear axes

- Even up to 50% highest performance than old generation milling machine

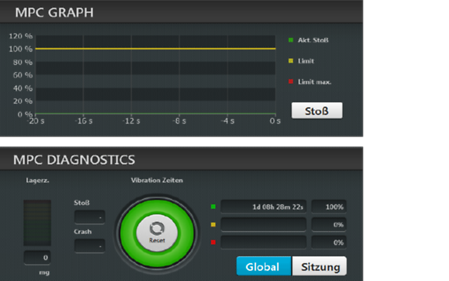

Precision & Quality

Best precision & process stability thanks to direct measuring system & advanced thermal compensation

- Linear scales in all linear axes for the highest accuracy of positioning

- Direct drive transmission in X & Y axis

- Improved accuracy of circular interpolation (ball-bar in all planes < 6 µm)

Sample applications

Automation

Open up the possibilities of automation

Increase productivity and quality, and operate 24/7. Our solutions offer extended machine uptime and support sustainability. Optimize your processes with our innovative automation solutions!