DMP 35

Vertical high speed machining center

Max. X-axis travel

350 mm

13.8 in.

Max. Y-axis travel

420 mm

16.5 in.

Max. Z-axis travel

380 mm

15 in.

Max. workpiece diameter

290 mm

11.4 in.

Max. workpiece height

580 mm

22.8 in.

Max. workpiece weight

400 kg

881.8 lbs.

Max. workpiece length

740 mm

29.1 in.

Max. workpiece width

420 mm

16.5 in.

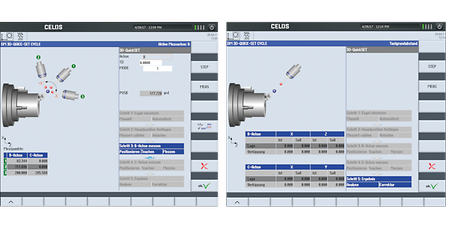

Control & software alternatives

SIEMENS

Highlights

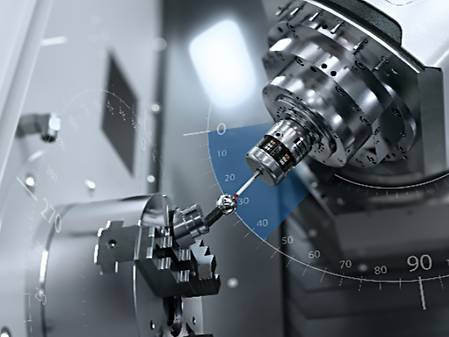

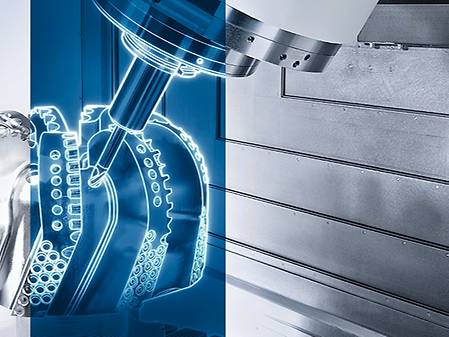

Compact, powerful and dynamically

- 15,000 rpm inline spindle with up to 57.53 ft.lb.; 24,000 rpm inline spindle with up to 35.40 ft.lb. optional available

- Up to 0.004 lbs. acceleration for quick chip-to-chip-time of only 1.5 seconds

- Machining of complex parts based on optional 5-axis simulataneous ability

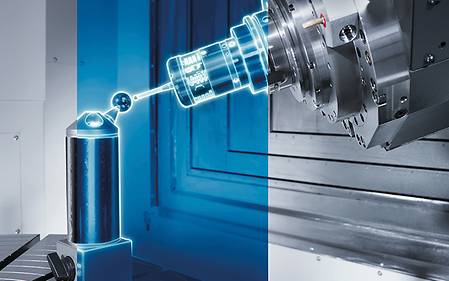

Highest precision and dynamics in the field of production

- Comprehensive cooling measures and direct absolute path measuring system in basic machine

- Highest rigidity and milling performance with rapid traverses of 2,362.20 in./min in all axes

- Comprehensive portfolio of chip conveyors and coolant systems

Latest technology and solutions for an even more efficient machining

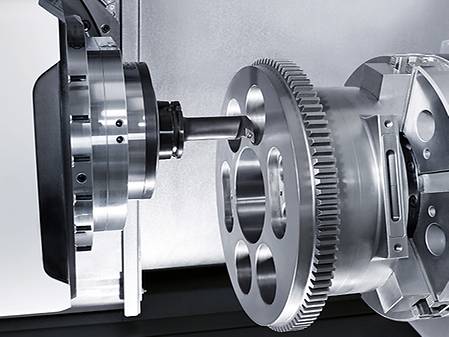

- Automated 6-side complete machining in the field of medical as well as production

- Maximum spindle stiffness based on spring preloaded bearings

- Comprehensive portfolio of chip conveyors and coolant systems

The most compact and powerful vertical machining center in his class

Highest precision, rigidity as well as maximum flexibility in the field 3-axis and 5-axis machining

- Minimal footprint of only 33.90 ft²

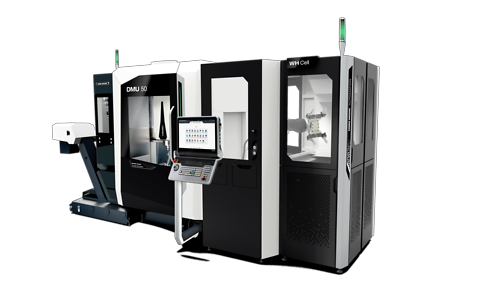

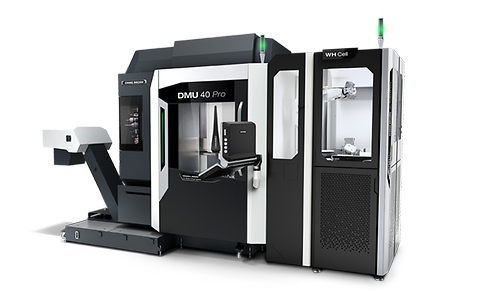

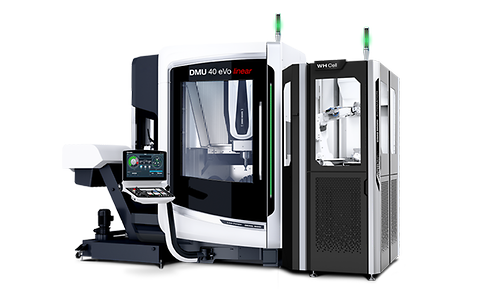

- Best automation integration with workpiece handling system WH 3

- Highly dynamic tool magazine with a chip-to-chip time of only 1.5 seconds

- Comprehensice cooling measures for a high thermal longterm accuracy

Sample applications

Automation

Standard automation and customised solutions in the VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customised automation solution for flexible manufacturing systems: