DMF 600|11 (FD, linear)

Largest DMF working area with 6 m travel

Max. X-axis travel

6000 mm

236.2 in.

Max. Y-axis travel

1100 mm

43.3 in.

Max. Z-axis travel

1050 mm

41.3 in.

Max. workpiece diameter

1400 mm

55.1 in.

Max. workpiece height

1100 mm

43.3 in.

Max. workpiece weight

12000 kg

26455.5 lbs.

Max. workpiece length

7200 mm

283.5 in.

Max. workpiece width

1100 mm

43.3 in.

Control & software alternatives

SIEMENS

HEIDENHAIN

Highlights

Largest DMF working area with 6 m travel and 12.000 kg table load

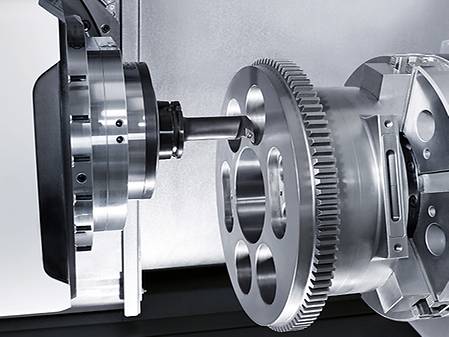

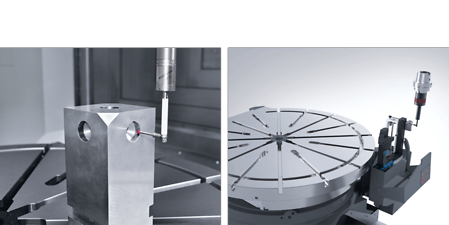

- 4-axis machining with B-axis for workpieces up to 7,200 x 1,100 x 1,100 mm and 12,000 kg

- 5-axis machining with integrated NC table (optional) for workpieces up to Ø 1,400 x 1,050 mm and 2,000 kg

- Partition wall (optional) for 2 independent working areas 3,600 x 1,100 x 1,100 mm

Highest stiffness and damping

- 3 linear guides in the X-axis and a one-piece machine bed made of gray cast iron

- High accuracy and cutting performance in total working area

- Best surface quality with X-Linear drive, Y/Z with direct cooled & grinded ballscrews

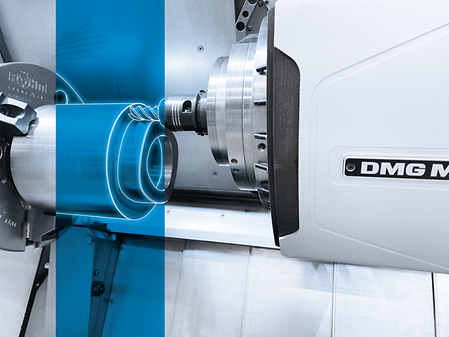

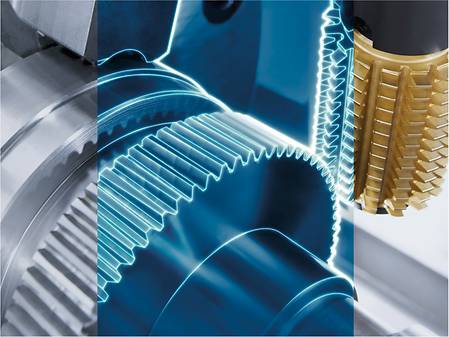

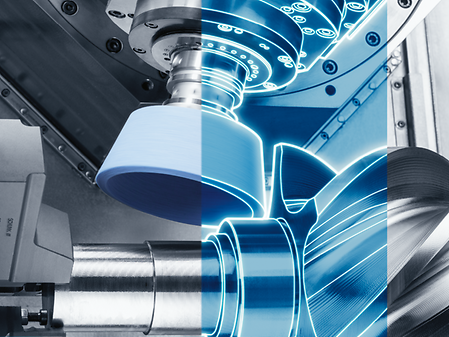

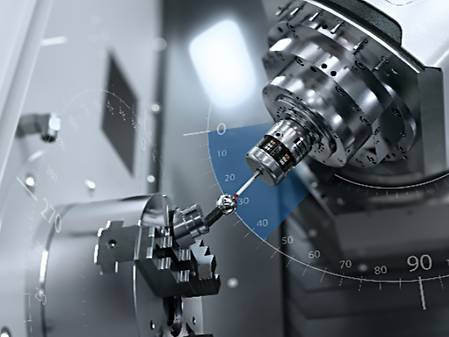

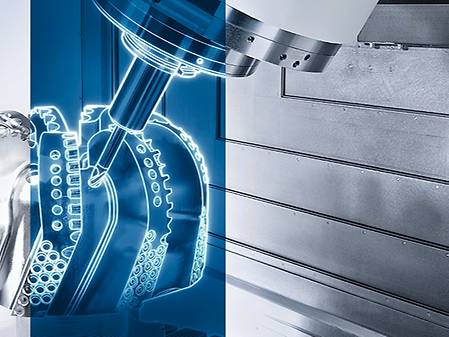

Large spindle variety & process integration

- speedMASTER (ISO 40) up to 24,000 rpm or 200 Nm

- powerMASTER (ISO 50) spindles up to 16,000 rpm or 430 Nm

- Process integration: Mill-Turn, gearSKIVING, grinding, fine boring, deep hole drilling

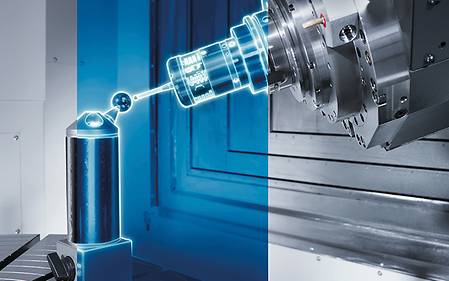

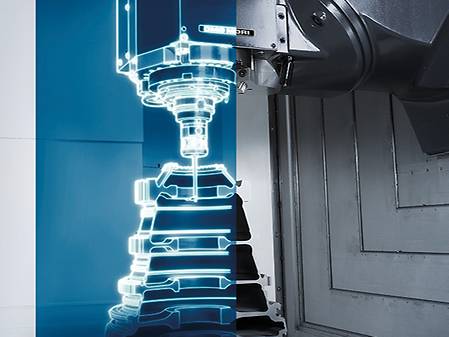

Highest productivity on your shopfloor

- Collision-free tool change outside the working area with a maximum capacity of 300 tools

- Dynamic 3-/4- or 5-axis machining with high feed rates in the linear and rotary axes

- High dynamics in the basic version with 42 m/min and maximum dynamics in the linear version with up to 80 m/min

- Automation interfaces with and without partition walls – also for alternating loading (pendular machining mode),, e.g. Robot or AMR for high machine utilization

- Wide range of working table options—perfect for all requirements

Sample applications

Automation

Standard automation and customised solutions in the VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customised automation solution for flexible manufacturing systems:

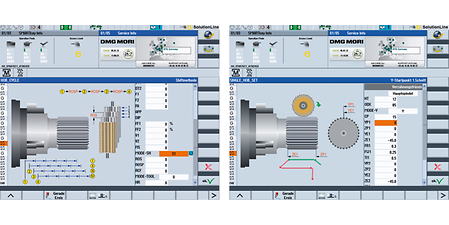

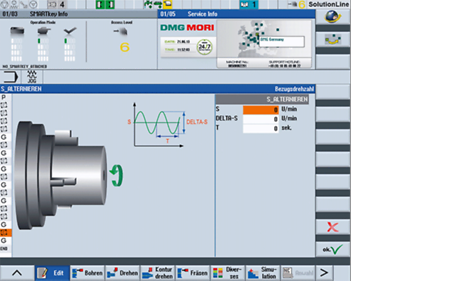

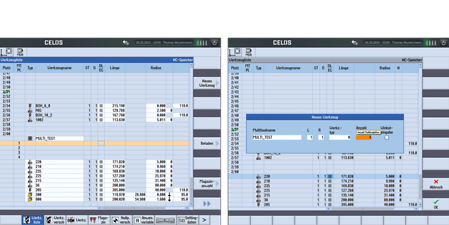

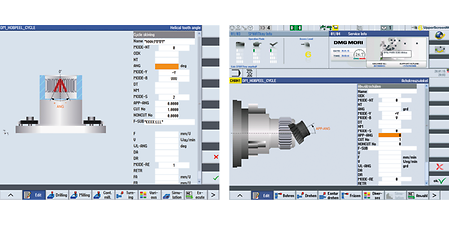

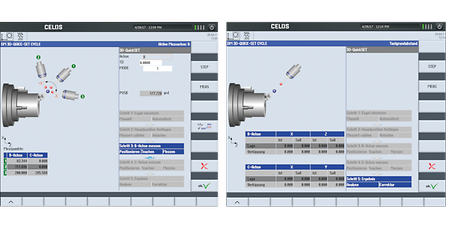

Control & software

CELOS

Integrated digitization of the DMG MORI machines & the shop floor:

- CELOS Machine: APP-based user interface with access to all production-related information

- CELOS Manufacturing: 27 CELOS APPs for the optimal preparation & processing of orders

- Digital Factory: Continuous digital workflows from planning to production & service