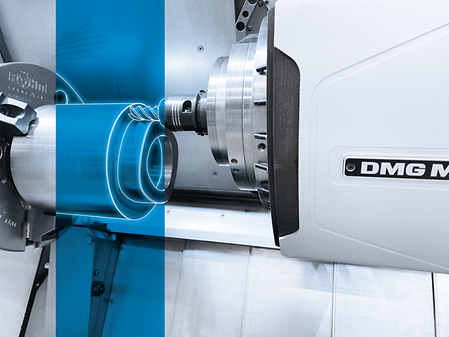

DMF 400|11 (FD, linear)

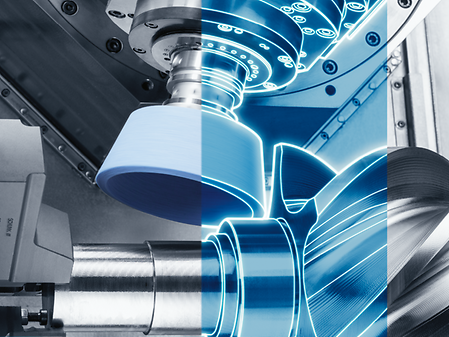

Traveling column machine of next generation for 5-axis simultaneous machining

Highlights

Maximum Flexibility

- Large working area and modular platform concept is the right solution for every request

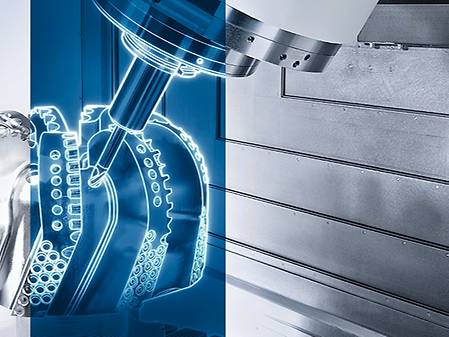

- 4-axis machining with B-axis and 5-axis with integrated rotary table (optional)

- Mill-Turn Technology for highly complex geometrics on one machine (optional)

Constant rigidity enables a high chip volume and a maximum productivity

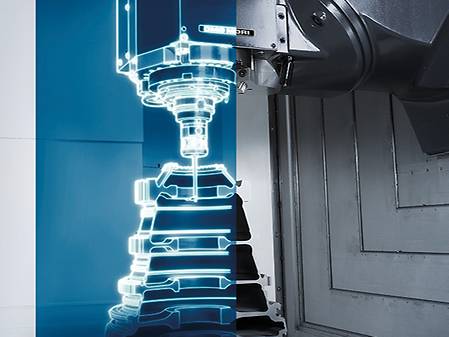

- New basic construction with constant overhang in the complete working area

- 3 linear guide ways in X-axis and single piece machine bed made of cast iron

- Spindles from 12,000 to 20,000 rpm and up to 430 Nm (SK40/ HSK-A63, SK50/HSK-A100)

High accuracy and best surface quality of the machined workpieces

- High thermal stability based on expensive cooling measures, e.g. internal cooled ballscrews

- Helical toothed belt and grinded ball screws in all axes

- Dynamic package with linear drive in X-axis and higher acceleration and feed rate in X,Y,Z-axis

Maximum productivity for your shopfloor

- Collision free tool change outside of the working area

- Tool magazine with up to 120 pockets and a tool length of up to 400 mm (540 mm HSK-A100)

- High variety of machine table options - perfect for all requirements

- Reduction of down time based on the partition wall (optional)

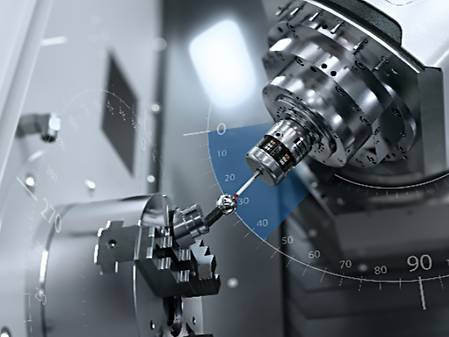

- Increase of productivity based on DMG MORI Technology Cycles, e.g. angularTOOL

Sample applications

Automation

Standard automation and customized solutions in VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customized automation solution for flexible manufacturing systems:

- Interface for robot handling (one working area)

- Interface pendelum machining with partition wall

Holistic automation on the shop floor

- Collaborative automation solution with free layout design

- Omnidirectional movement for minimal space requirements (turning radius 0m)

- Basis for additional tasks, e.g. B. tool handling, chip disposal, etc.

- Material transport from Euro pallets 1,200 x 800 mm

- Maximum transport weight of up to 2,000 kg

- Security based on Sick and Siemens technology

- Autonomous transport of material pallets

- Transport of different load carriers

- Integration into DMG MORI automation systems for workpiece handling – exchange of finished part and raw part pallets

- Integration into existing processes

- Scalable and expandable at a later date

- Autonomous transport of chip containers

- Automatic transport order from the master computer

- Extended autonomy of the machine tool

- Material and chip transport can be combined

- Tool identification in the standard

- Autonomous transport and exchange of tools between machines and tool storage systems

- Max. tool dimensions ø 280 / 400 mm

- Max. tool weight 30 kg

- Transport weight 720 kg (24× 30 kg)

- Maximum number of tools: 24 pcs

Pallet automation with maximum flexibility through free layout design

- Modular concept with flexible layout design

- Driverless transport systems without guide rails or tracks

- Collaborative: Man and machine in one system

- Navigation through natural navigation

- Pallet sizes from 500 × 500 mm to 1,600 × 1,250 mm

- Workpieces up to 5,000 kg and ø 1,600 mm

Free accessibility

- Best visibility into the workspace at any time

- Manual or crane loading still possible

- Collaborative system – man and machine in one system

Modular concept with free layout design

- No safety housing for the automation system necessary

- Free positioning possibility of the individual modules

- Subsequent integration into existing production

Simple expansion of automation system

- Additional shelf modules to increase the number of storage places

- Additional AMRs can be integrated in the system

- Machines with an automation interface can be integrated very quickly afterwards

Minimum space requirement

- Free pallet handling system without fixed installation requirements on hall floor

- AMR paths remain walkable and passable

- Laser scanners guarantee personal protection in driving direction

- Omnidirectional movement for minimum space requirements (turning circle 0m)

- Flexible automation concept - Automation of different machine types with one system

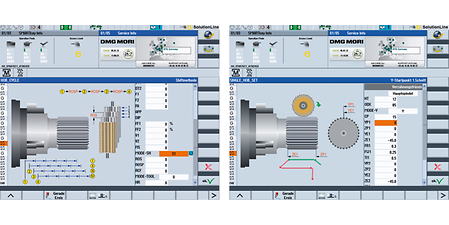

Control & software

- Milling of oval and polygonal geometries

- Machining of excentric face polygons possible

- Simple selection of suitable machining strategies

- Simple parametric definition of the shaft-hub connection according to DIN 32711 and DIN 32712

- Enable the machining of small workpieces or those made of long-chipping materials. The perfect complement to Polygon / Oval-Turning.

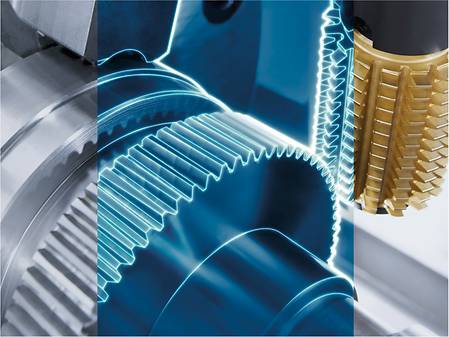

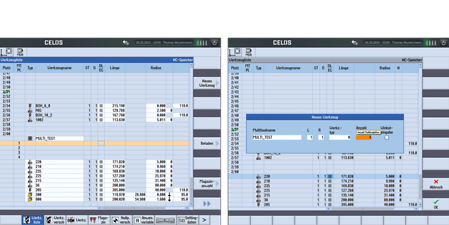

- Programming of the gearing parameters via dialog input

- For spur gear, helical gear and worm gear

- Gear cutters and disk cutters can be used

- Maximized tool life by shifting of the cutter

- Achievable quality ≤ DIN 7

- Gear profile modifications easy to handle

- Use of regrinded tools

- Error prevention by monitoring (e. g. wrong axis cross angle, or wrong turning speed, or turning direction)

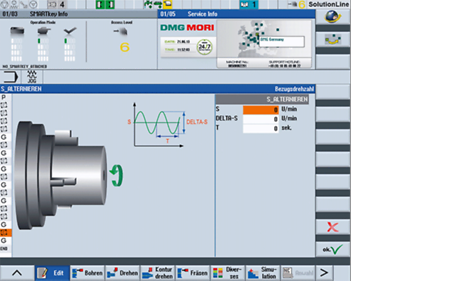

- Easy to operate through three parameters and without additional sensors

- Avoiding vibrations by means adaptation of the speed

- Application for the main spindle and counter spindle, or for milling machines with FD tables with Direct Drive

- No manual intervention by the operator

- Identical repeatability for all components

- Increased process safety for special applications by avoiding vibrations. example, When using long thin drills or for milling parts with critical clamping

- Full utilization of the working space during internal machining of high workpieces with long tools

- Positional changes of the B axis during the turning are balanced by the X and Y axes

- The Z-axis remains at the retracted position while the B axis is moving

- Easy programming

- Collision-free plunging in the workpiece

- Safely coming out from the workpiece after machining

- Efficient use of multi-tip turning tools with more than one cutting edge on turn & mill

- Several "sister tools" on one main tool holder

- Reduction of tool change times

- Saves tool magazine space

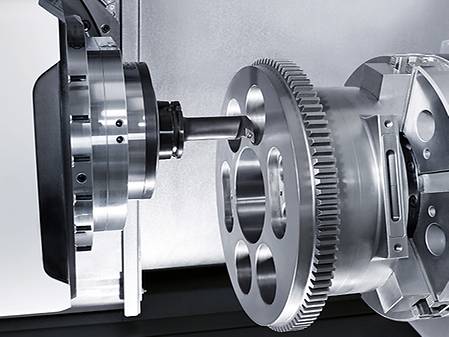

- Straight and helical external or internal spur gears and splines

- Arrow teeth with tooth offset Turn-mill machines

- Ball-shaped toothing by mathematical transformation of the 6th virtual axis

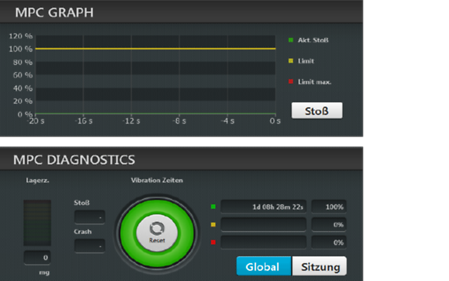

- Vibration monitoring in the process

- Rapid shutdown in case of a crash

- Manual retraction even in swiveled machining plane

- NEW: Torque monitoring

- New: Recommended with Protection Package for CTX TC machines

- Avoiding tool breakage

- Increase in machine availability

- Damage reduction

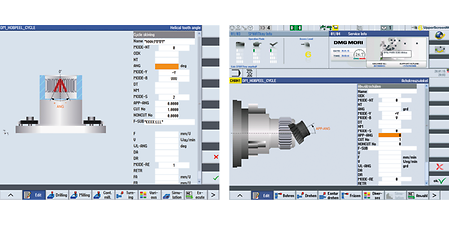

Turning

- Turning, milling and grinding in one clamping

- Grinding cycles for internal, external and face grinding as well as dressing cyclesn

- Body-borne sound sensors for start-up and dressing

- Full integration of measurement module for relative and absolute LIVE-Measuring – parallel to main time

Milling

- Better surface quality through integration of the grinding technology

- Grinding cycles for internal, external and face grinding as well as dressing cycles

- Body-borne sound sensors for start-up and dressingn

- 1,300 l Cooling system with integrated centrifugal filter for The filtration of particles > 10 μ

- AKZ nozzle unit optionally available for best possible Flushing of the grinding gap

- Expansion of the technological limits of the CTX TC

- Surface accuracy < 0.4 μm

- Roundness < 5 μm

- Quality IT5 for ø > 30 mm

- Surface accuracy < 0.4 μ

- Roundness < 5 μ

- Quality 5 for ø < 120 mm

- Quality 4 for ø > 120 mm

Turning

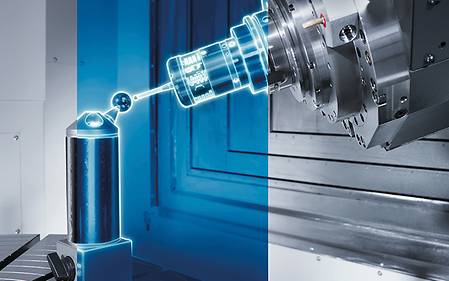

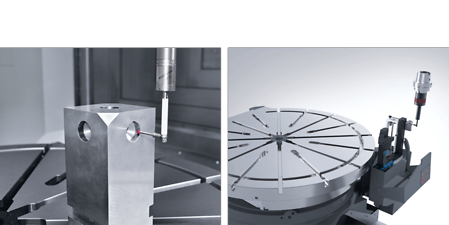

- Measurement and correction of the position of turning and Pivot axes (C4, C3, B)

- Sag compensation possible

- Can be used in combination with standard probes from customers (recommended Renishaw, Blum)

Milling

- Toolkit for checking and correcting the kinematic accuracy of 4- and 5-axis machine configuration

- All head variations and table axes

- Reliable re-calibration of the machine before a highly precise processing

- Continuous documentation of machine accuracy

- No rejected parts due to unknown Geometric-deviations

- Periodic recalibration of the machine with comprehensive documentation

- Highest kinematic accuracy in self-regulation

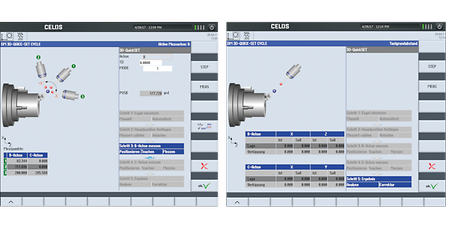

- With interpolation turning, the tool cutter follows a circular movement, where the cutter is always oriented towards the center Of the circle.

- Possible for external and internal machining

- Synchronization and tool path controlled by the cycle

- NEW: in version 2.0 complex turning contours are possible (currently only available on the DMU 50, other machine types will follow)

- Easy manufacturing of sealing surfaces where milling operation might not be possible.

- Complete component processing in one clamping possible

- Reduced investment costs for tools

- Productive complete processing

- Cost-effective gear cutting on standard machine with standard tools

- Flexible for different gear geometries

- Quality inspection in the process

- Program creation based on blank drawings and gear data

- Optimization of workpiece orientation e.g. after heat treatment

- Interface for coordinate measuring device (Klingenberg, Leitz, Zeiss)

- Process-oriented adjustment of the feed rate n relation to the table loading

- Minimization of machining time with maximization of the component quality

- NEW: Now also available for CTX TC. Ideal machining result with the highest machine dynamics*

*without consideration of feed weight

- Measurement of webs and grooves on components

- Measurement of diameter in difficult to access places

- Available with manual and retractable Calibration unit Package content

- L-Measuring probe according to Customer-specific design

- Flexible application possibilities

- In process measurement

Service & training

Downloads & Technical Data

Special technical articles, analyses, and background information on topics that move our industry.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Get access to many useful digital functions and services and have all important data at a glance. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Unlock access to your Share Hub and many other functions and services. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

For general enquiries, please use our contact form.

For service and spare parts enquiries please use the my DMG MORI portal: https://us.mydmgmori.com/

Thank you very much for your interest in our products.

To download our brochures please fill in the form below.

If you accept the storage of cookies, this form appears only once during your visit.