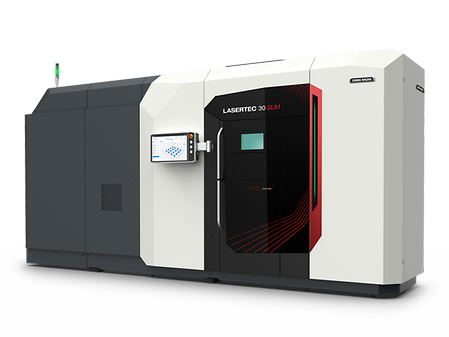

LASERTEC 30 SLM 3rd Generation

Additive Manufacturing by slective laser melting (SLM)

Highlights

Additive Manufacturing by selective laser melting (SLM) in powder bed

- Highly complex components with function integration

- Internal close-contoured cooling channels

- Weight optimisation due to lattice and honeycomb structures as well as topology-optimised components

- Simultaneous build-up of different designs

- Shorter product development times by quickly available prototypes made of series materials

100% machine tool design for SLM technology

- Build volume of 325 x 325 x 400 mm

- Single-, Dual- or Quad-Laser with high-precision optics and full overlap

- Exchangeable build container for reduced job-to-job time

- Bi-directional recoating with collision protection system

- CELOS X with easyAM – guided workflows for simplified machine operation and maintenance

New benchmak for robustness and repeatability

- Thermosymmetric casting frame for highest rigidity

- Floating process chamber for minimized thermal shifts

- Active temperature compensation for z-axis positioning

- Protective glass monitoring to detect smoke residues and weld penetrations

- Powder bed monitoring for anomaly detection

rePLUG – The powder module for fast material change

- Automated powder handling: Integrated powder-recycling for maximum efficiency and highest work-safety due to closed material cycle

- One material per rePLUG – Any expansion of the material range due to modular changing system for contamination-free changeover

- Integrated sieving and powder drying functionality under inert gas atmosphere

- Industrialized powder fill-in-interfaces and precise weight detection in main tank

- Optional: rePLUG FLEX - the additional powder module, especially developed for the material and process parameter development on the series system

Sample applications

Control & software

CELOS X: New design with focus on simplicity and transparency

- easyAM – Guided workflows for machine operation

- Maintenance app for active assistance through regular machine servicing tasks

- Easy integration of customer-specific requirements due to modularity

- State-of-the-art software architecture ensures reliable performance

- Connectivity: Supports a variety of interfaces such as OPC / UA, MQTT, MTConnect, and more