LASERTEC 12 SLM

Additive Manufacturing by selective laser melting (SLM)

Highlights

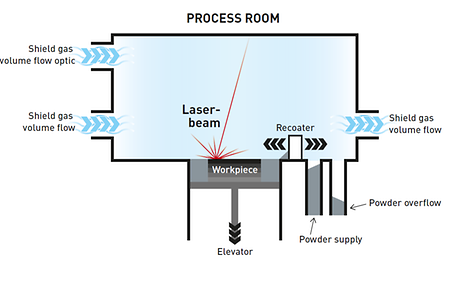

Additive Manufacturing by selective laser melting (SLM) in powder bed

- Highly complex components with function integration

- Internal close-contoured cooling channels

- Weight optimisation due to lattice and honeycomb structures as well as topology-optimised components

- Simultaneous build-up of different designs

- Functional prototypes made of series materials

Additive Manufacturing with a 4.9 x 4.9 x 7.9 in. (X / Y / Z) building volume

- High precision building of 3D parts with a focus diameter of only 0.0014 in.

- Application-specific fibre laser sources from 200 W as standard to 400 W optional

- Optimised shield gas volume flow for highest component quality with minimum Argon consumption

- Open system: Individual adjustment of all machine settings and process parameters as well as unrestricted selection of the material supplier

- End-to-end competence with integral process understanding from drawing to finished part: DMG MORI Process Chains for pre- and post-processing of additively built parts

rePLUG – The powder module for fast material change

- Automated powder handling: Integrated powder-recycling for maximum efficiency and highest work-safety due to closed material cycle

- One material per rePLUG – Any expansion of the material range due to modular changing system

- Contamination-free change between different materials in <2 hours

- High process autonomy due to powerful duo filter system (filter change without process interruption) as well as large powder reservoir (no manual refilling required in the process)

- Optional: rePLUG RESEARCH The additional powder module, especially developed for the material and process parameter development on the series system

Sample applications

Control & software

CELOS: Consistent software solution from CAM programming up to machine control

- Intuitive machine operation due to touchscreen and APP-based control

- RDesigner: CAM Programming directly on the machine control

- HEAT-Calculation: Patented advance calculation of mass distribution and automatical adjustment of all laser parameters for top component quality

- Monitoring tools: Camera-based process monitoring of the build-up and coating quality