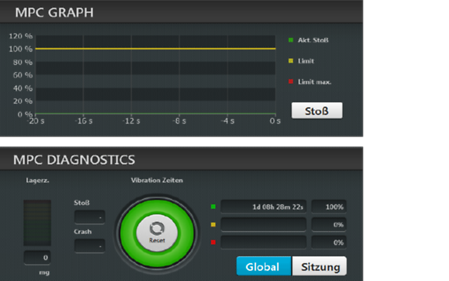

MPC 2.0 – Machine Protection Control

- Vibration monitoring in the process

- Rapid shutdown in case of a crash

- Manual retraction even in swiveled machining plane

- NEW: Torque monitoring

- New: Recommended with Protection Package for CTX TC machines

Highlights

Customer Benefits

- Avoiding tool breakage

- Increase in machine availability

- Damage reduction

Downloads

Technical Data

● available

Horizontal machining center with highest stability, precision and dynamics

Horizontal machining center with highest stability, precision and dynamics

5-axis machining for maximum flexibility thanks to a swiveling rotary table supported on both sides for components up to ø840 x 770 mm and 600 kg

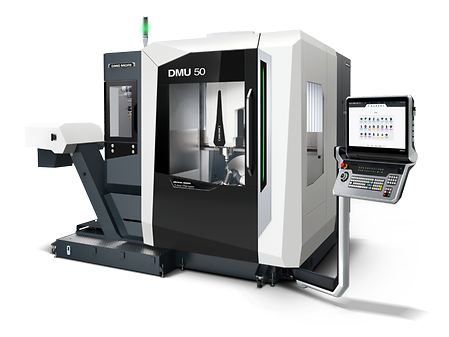

CNC Universal Milling Machine with swivel rotary table

Compact, precise, reliable process with >2 g acceleration and spindle speeds up to 60,000 rpm

Traveling column machine of next generation for 5-axis simultaneous machining

Traveling column machine of next generation for 5-axis simultaneous machining

Largest DMF working area with 6 m travel

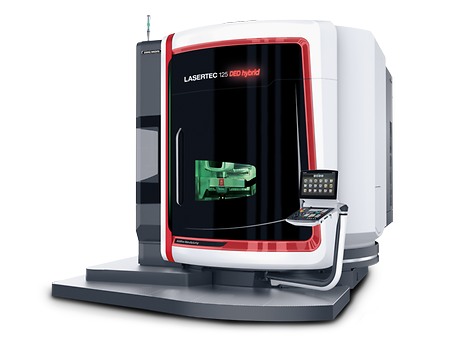

Hybrid Additive Manufacturing: Building, repairing and coating of high value metal parts up to 4,409 lbs.

The next Era of Metal Additive Manufacturing!

Hybrid Machining: Additive Manufacturing and Turning / Milling in one Machine

The multi-talented solution for high-precision 5-axis machining – standalone or automated!

The multi-talented solution for high-precision 5-axis machining – standalone or automated!

When productivity and flexibility double, the future of manufacturing emerges.

When productivity and flexibility double, the future of manufacturing emerges.

The entry machine for 5-axis simultaneous machining

Traveling column machine of next generation for 5-axis simultaneous machining

Traveling column machine of next generation for 5-axis simultaneous machining

5-axis ULTRASONIC precision machining of hard-brittle materials

Special technical articles, analyses, and background information on topics that move our industry.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Get access to many useful digital functions and services and have all important data at a glance. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Unlock access to your Share Hub and many other functions and services. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

For general enquiries, please use our contact form.

For service and spare parts enquiries please use the my DMG MORI portal: https://us.mydmgmori.com/

Thank you very much for your interest in our products.

To download our brochures please fill in the form below.

If you accept the storage of cookies, this form appears only once during your visit.