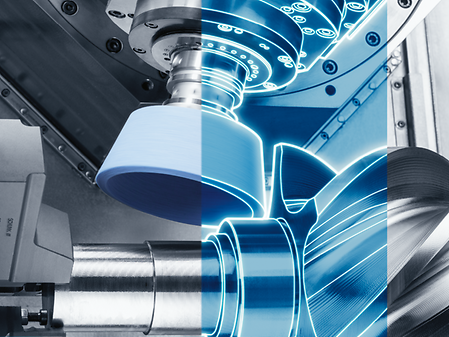

Grinding

Turning

- Turning, milling and grinding in one clamping

- Grinding cycles for internal, external and face grinding as well as dressing cyclesn

- Body-borne sound sensors for start-up and dressing

- Full integration of measurement module for relative and absolute LIVE-Measuring – parallel to main time

Milling

- Better surface quality through integration of the grinding technology

- Grinding cycles for internal, external and face grinding as well as dressing cycles

- Body-borne sound sensors for start-up and dressingn

- 1,300 l Cooling system with integrated centrifugal filter for The filtration of particles > 10 μ

- AKZ nozzle unit optionally available for best possible Flushing of the grinding gap

Highlights

Turning Customer Benefits

- Expansion of the technological limits of the CTX TC

- Surface accuracy < 0.4 μm

- Roundness < 5 μm

- Quality IT5 for ø > 30 mm

Milling Customer Benefits

- Surface accuracy < 0.4 μ

- Roundness < 5 μ

- Quality 5 for ø < 120 mm

- Quality 4 for ø > 120 mm

Downloads

Technical Data

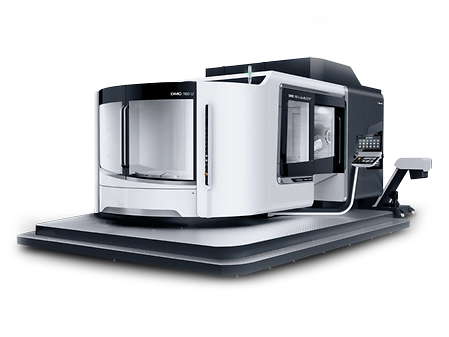

DMU / DMC duoBLOCK

CELOS with SIEMENS

●

●

● available

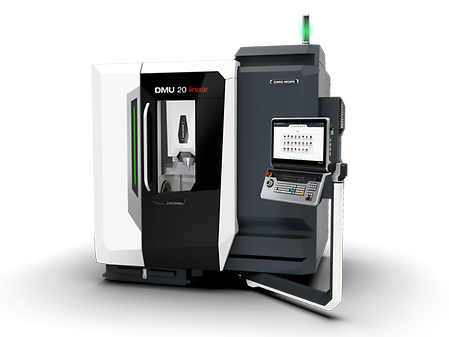

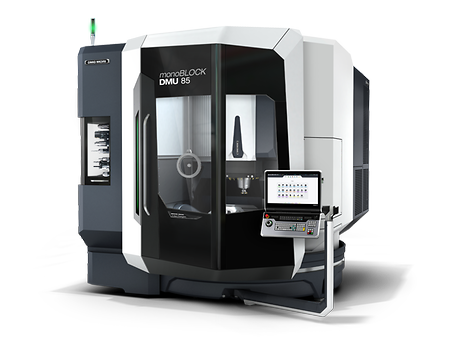

The monoBLOCK series has a machine concept for every sector

The monoBLOCK series has a machine concept for every sector

The monoBLOCK series has a machine concept for every sector

The monoBLOCK series has a machine concept for every sector

The most precise 5-axis simultaneous machine within DMG MORI

Traveling column machine of next generation for 5-axis simultaneous machining

Traveling column machine of next generation for 5-axis simultaneous machining

Largest DMF working area with 6 m travel

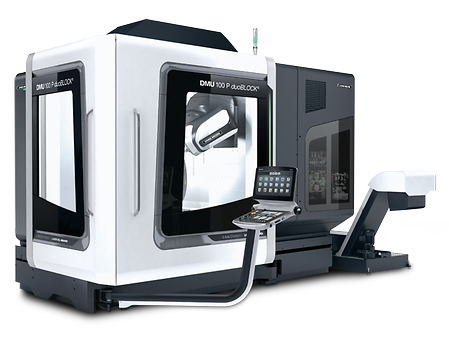

With the new duoBLOCK series, every component becomes a masterpiece.

With the new duoBLOCK series, every component becomes a masterpiece.

With the new duoBLOCK series, every component becomes a masterpiece.

With the new duoBLOCK series, every component becomes a masterpiece.

With the new duoBLOCK series, every component becomes a masterpiece.

With the new duoBLOCK series, every component becomes a masterpiece.

With the new duoBLOCK series, every component becomes a masterpiece.

With the new duoBLOCK series, every component becomes a masterpiece.

The next Era of Metal Additive Manufacturing!

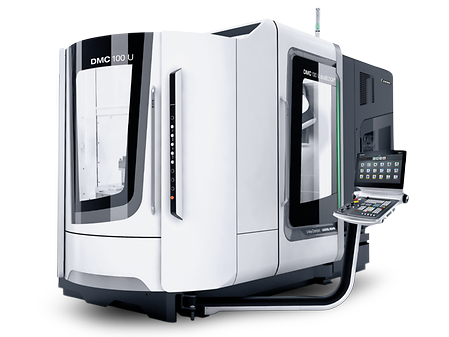

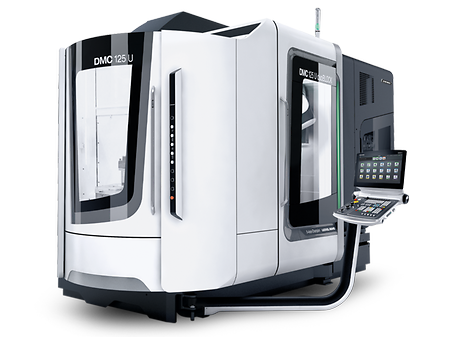

5-axis simultaneous machining of workpieces up to ø1,040 x 590 mm and 1,500 kg on 12.3 m²

For the highest demands in the 5-axis universal range of workpieces up to Ø700 x 550 mm and 500 kg on 9 m²

The multi-talented solution for high-precision 5-axis machining – standalone or automated!

Traveling column machine of next generation for 5-axis simultaneous machining

Traveling column machine of next generation for 5-axis simultaneous machining

The monoBLOCK series, a machine concept for every sector

Special technical articles, analyses, and background information on topics that move our industry.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Get access to many useful digital functions and services and have all important data at a glance. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Unlock access to your Share Hub and many other functions and services. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

For general enquiries, please use our contact form.

For service and spare parts enquiries please use the my DMG MORI portal: https://us.mydmgmori.com/

Thank you very much for your interest in our products.

To download our brochures please fill in the form below.

If you accept the storage of cookies, this form appears only once during your visit.