gearHOBBING

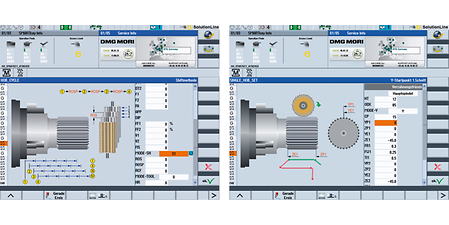

- Programming of the gearing parameters via dialog input

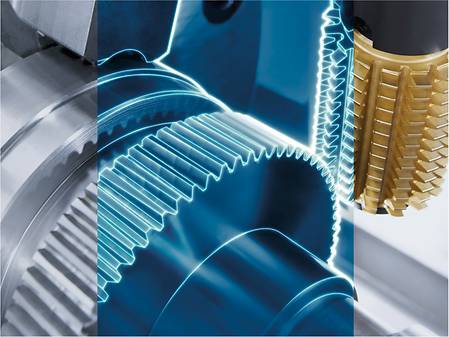

- For spur gear, helical gear and worm gear

- Gear cutters and disk cutters can be used

- Maximized tool life by shifting of the cutter

- Achievable quality ≤ DIN 7

Highlights

Customer benefits

- Gear profile modifications easy to handle

- Use of regrinded tools

- Error prevention by monitoring (e. g. wrong axis cross angle, or wrong turning speed, or turning direction)

Downloads

Technical Data

● available

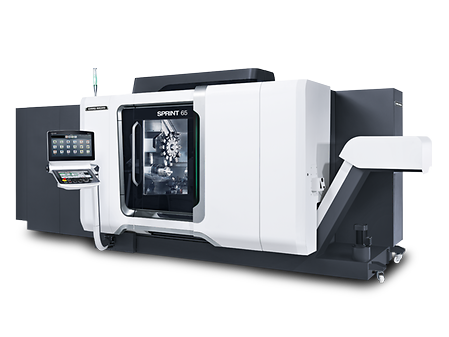

4-axis production turning with 3 Y-axes, B-axis and 3 turrets for up to 36 driven tools for max diameter 2.6 in.

4-axis production turning with 3 Y-axes, B-axis and 3 turrets for up to 36 driven tools for max diameter 3.7 in.

Traveling column machine of next generation for 5-axis simultaneous machining

Traveling column machine of next generation for 5-axis simultaneous machining

Largest DMF working area with 6 m travel

Hybrid Machining: Additive Manufacturing and Turning / Milling in one Machine

Traveling column machine of next generation for 5-axis simultaneous machining

Traveling column machine of next generation for 5-axis simultaneous machining

The medium size turning machine with two turrets

One Y axis – up to 36 tool positions

Special technical articles, analyses, and background information on topics that move our industry.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Get access to many useful digital functions and services and have all important data at a glance. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Unlock access to your Share Hub and many other functions and services. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

For general enquiries, please use our contact form.

For service and spare parts enquiries please use the my DMG MORI portal: https://us.mydmgmori.com/

Thank you very much for your interest in our products.

To download our brochures please fill in the form below.

If you accept the storage of cookies, this form appears only once during your visit.