PH-AMR

Pallet automation with maximum flexibility through free layout design

- Modular concept with flexible layout design

- Driverless transport systems without guide rails or tracks

- Collaborative: Man and machine in one system

- Navigation through natural navigation

- Pallet sizes from 500 × 500 mm to 1,600 × 1,250 mm

- Workpieces up to 5,000 kg and ø 1,600 mm

Highlights

Free accessibility

- Best visibility into the workspace at any time

- Manual or crane loading still possible

- Collaborative system – man and machine in one system

Modular concept with free layout design

- No safety housing for the automation system necessary

- Free positioning possibility of the individual modules

- Subsequent integration into existing production

Simple expansion of automation system

- Additional shelf modules to increase the number of storage places

- Additional AMRs can be integrated in the system

- Machines with an automation interface can be integrated very quickly afterwards

Minimum space requirement

- Free pallet handling system without fixed installation requirements on hall floor

- AMR paths remain walkable and passable

- Laser scanners guarantee personal protection in driving direction

- Omnidirectional movement for minimum space requirements (turning circle 0m)

- Flexible automation concept - Automation of different machine types with one system

Videos

Technical Data

Technical data

Pallet sizes (mm)

Dimensions (mm)

Max. Lifting height (mm)

Max. Driving speed (km/h)

Navigation

PH-AMR 750

750 kg

500 x 500

630 x 630

D 630

D 800 x 630

1,500 x 1,000 x 2,200

1,250

6

Laser

PH-AMR 1500

1.500 kg

630 x 630

D 630

D 800 x 630

2,600 x 2,000 x 2,930

2,010

6

Laser

PH-AMR 3000

3.000 kg

800 x 800

D 900 x 800

1,000 x 800

D 1,100

3,110 x 2,160 x 3,200

2,010

6

Laser

PH-AMR 5000

5.000 kg

D 1,400

1,600 x 1,250

3,710 x 2,600 x 2,500

2,010

6

Laser

● available

x available on request

The solution-based CMX V - from now on with IoTconnector and direct measuring system in standard

The solution-based CMX V - from now on with IoTconnector and direct measuring system in standard

The solution-based CMX V – now with IoTconnector and direct measuring system in standard

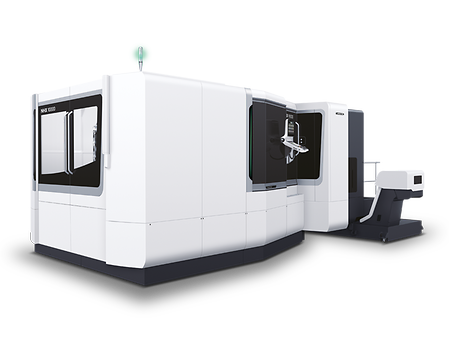

Expert on machining of large and difficult-to-cut workpieces

Evolution in universal machining. Flexible, productive and process-safe.

Evolution in universal machining. Flexible, productive and process-safe.

5-axis machining for maximum flexibility thanks to a swiveling rotary table supported on both sides for components up to ø840 x 770 mm and 600 kg

Evolution in universal machining. Flexible, productive and process-safe.

Evolution in universal machining. Flexible, productive and process-safe.

Your powerful and flexible 5-sided machining solution – from now on with direct measuring system in standard

Your powerful and flexible 5-sided machining solution – from now on with direct measuring system in standard

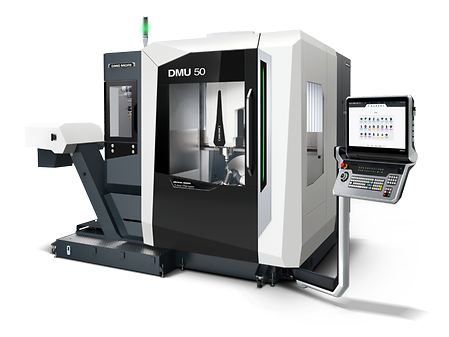

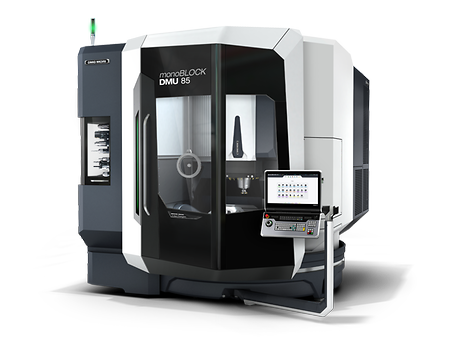

CNC Universal Milling Machine with swivel rotary table

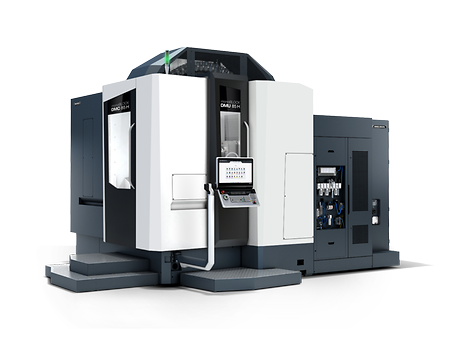

The monoBLOCK series has a machine concept for every sector

The monoBLOCK series has a machine concept for every sector

The monoBLOCK series has a machine concept for every sector

The monoBLOCK series has a machine concept for every sector

The monoBLOCK series has a machine concept for every sector

The monoBLOCK series has a machine concept for every sector

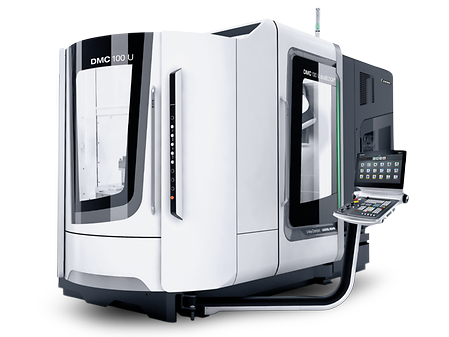

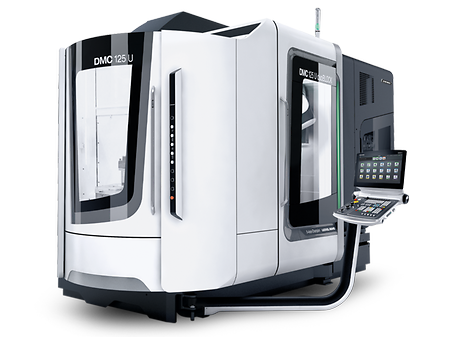

Universal Machining Center

Universal Machining Center

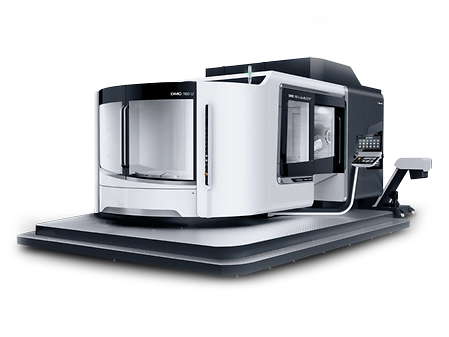

Traveling column machine of next generation for 5-axis simultaneous machining

Traveling column machine of next generation for 5-axis simultaneous machining

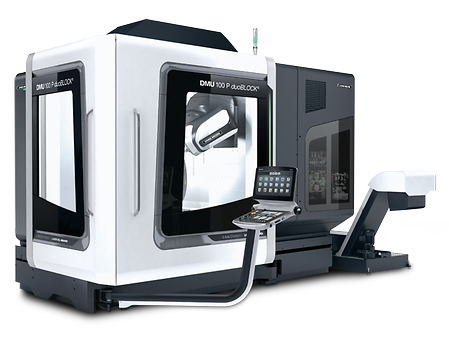

With the new duoBLOCK series, every component becomes a masterpiece.

With the new duoBLOCK series, every component becomes a masterpiece.

With the new duoBLOCK series, every component becomes a masterpiece.

With the new duoBLOCK series, every component becomes a masterpiece.

With the new duoBLOCK series, every component becomes a masterpiece.

With the new duoBLOCK series, every component becomes a masterpiece.

With the new duoBLOCK series, every component becomes a masterpiece.

With the new duoBLOCK series, every component becomes a masterpiece.

With the new duoBLOCK series, every component becomes a masterpiece.

With the new duoBLOCK series, every component becomes a masterpiece.

Universal ULTRASONIC Machining Centre

The next Era of Metal Additive Manufacturing!

5-axis simultaneous machining of workpieces up to ø1,040 x 590 mm and 1,500 kg on 12.3 m²

For the highest demands in the 5-axis universal range of workpieces up to Ø700 x 550 mm and 500 kg on 9 m²

The multi-talented solution for high-precision 5-axis machining – standalone or automated!

The multi-talented solution for high-precision 5-axis machining – standalone or automated!

When productivity and flexibility double, the future of manufacturing emerges.

When productivity and flexibility double, the future of manufacturing emerges.

Traveling column machine of next generation for 5-axis simultaneous machining

Traveling column machine of next generation for 5-axis simultaneous machining

The monoBLOCK series, a machine concept for every sector

The monoBLOCK series, a machine concept for every sector

High performance & precise vertical milling center for parts up to 78.7 in. length and 6613.9 lbs.!

Special technical articles, analyses, and background information on topics that move our industry.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Get access to many useful digital functions and services and have all important data at a glance. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Unlock access to your Share Hub and many other functions and services. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

For general enquiries, please use our contact form.

For service and spare parts enquiries please use the my DMG MORI portal: https://us.mydmgmori.com/

Thank you very much for your interest in our products.

To download our brochures please fill in the form below.

If you accept the storage of cookies, this form appears only once during your visit.