DMU 50 3rd Generation

Bestseller - More than 15,000 DMU 50 operational worldwide

5-axis machining with speedMASTER spindle as standard

HIGHLIGHTS

- 5-axis machining at up to 20,000rpm

- Swivelling rotary table for 5-axis simultaneous machining

- Tool magazine with 30 pockets as standard and optionally up to 120 magazine pockets

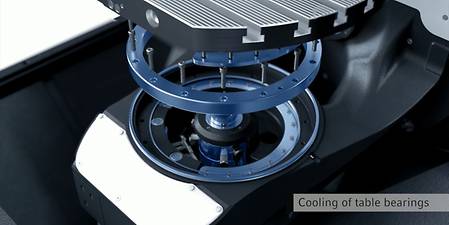

- Integrated cooling concept for unrivaled longterm precision

- Directly-driven ball screw drive for the best possible accuracy

- Linear scales in all axes

- Optimal automation from the side

BESTSELLER WITH TOP QUALITY FOR 5 µ PRECISION

The 3rd generation of the DMU 50 is a mechatronic masterpiece, 20 years on from the original version, and an absolute bestseller in the DMG MORI product range. Following on from the lightning start last year, 2018 sees over 800 machines in the production plan.

78 % more working area, 40 % faster rapids, 28 % more swivel angle, faster rotary-swivel speeds and power speedMASTER spindles with 36-month warranty and no limit on operating hours. This is combined with tool magazines for up to 120 tools and comprehensive cooling for outstanding precision down to 5 µ.

Overall, the 3rd generation DMU 50 offers decisive added value. This also applies to the diversity offered within the ERGOline portfolio with high-tech CNCs from SIEMENS, HEIDENHAIN and FANUC.

Due to its flexibility and versatility, the DMU 50 3rd Generation can be found in almost all sectors – from single part production right up to mass production. Additional static and dynamic rigidity is provided by the stable (monolithic) machine bed and low center of gravity. In combination with directly driven ball screw drives, linear scales and comprehensive cooling, it provides unique precision in this machine class. The DMU50 3rd Generation is therefore recommended as an ideal, costeffective means of getting ahead in the fascinating world of 5-sided or up to 5-axis simultaneous machining.