Complete automation and flexible integration from a single source

In automotive production, the requirements for manufacturing quality are of crucial importance, as they can affect the safety of vehicle occupants and other road users. The high quality of the components used guarantees the high reliability and durability of the vehicles produced. Faulty or imprecisely manufactured components can lead to malfunctions or, in the worst case, to serious accidents.

Initial Situation

The change in the mobility industry requires new strategies & solutions

With the switch to e-mobility, the automotive industry is in the midst of a profound structural change. New technologies and players are entering the market and the legal requirements in terms of quality, safety or environmental and climate protection are constantly changing. This development presents companies with many challenges, but also new opportunities: they need to rethink their investments, processes and supply chains in order to remain at the forefront of technology. At the same time, production must become more flexible and agile in order to adapt to the new market conditions.

Safety and efficiency requirements

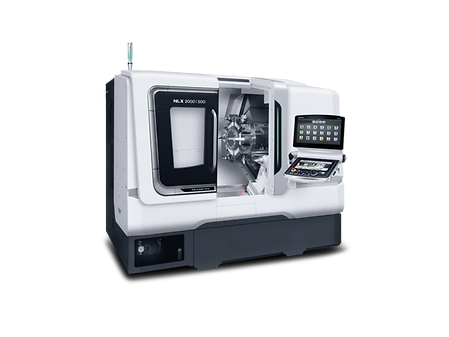

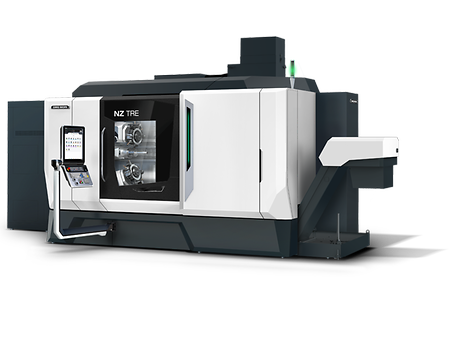

It is therefore essential for manufacturers to use high-quality, precise machine tools that can also perform automated tasks. This in turn has an impact on production efficiency: Precise, high-quality manufacturing processes reduce rejects and rework, thereby lowering production costs.

“If necessary we can produce around the clock. Reliability is essential here, which is why we trust in DMG MORI.“, says Herbert Drexler Founder and owner Drexler Automotive GmbH, which relies on CNC technology and automation solutions from DMG MORI.

The transition to e-mobility requires considerable investment in new technologies and systems. Hybrid and electric drives place high demands on material processing, production technologies and employee qualifications. Mobility poses major technical, financial and economic challenges for the automotive industry as a whole. The successful handling of these challenges will determine the future viability of companies.

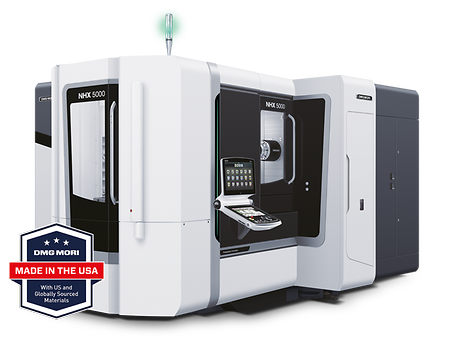

With its decades of expertise and customized solutions, DMG MORI is the ideal partner to successfully accompany automotive manufacturers and suppliers through this transformation process. Just like Grede Casting Integritiy LLC, a leading expert in the field of metal casting: “In a project of this size, there are always hurdles to overcome. DMG MORI mastered the installation professionally and on schedule at all times.”, says Mike Latwesen, General Manager at Grede in Menomonee Falls.

Value Added

Complete service for automotive production

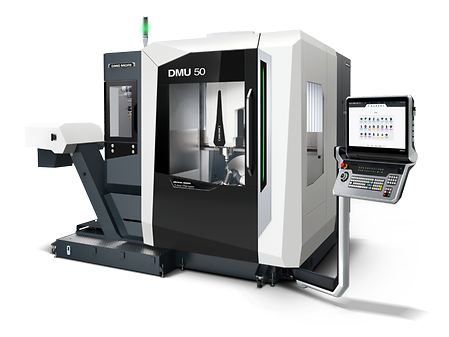

DMG MORI relies on the DTTC (Digital Twin Test Cut) for the pre-analysis of the production processes in order to analyze the expected production results before the start of the development of the production systems and, if necessary, to incorporate changes at this stage. This guarantees our customers the highest level of production quality during implementation.

High regulatory requirements for production

The regulatory requirements are also high. In the automotive industry, for example, the international quality standard IATF 16949 applies, which is based on ISO 9001 and regulates quality management in the development, production, installation and maintenance of automobiles. Certification to IATF 16949 is not directly a legal requirement, but in practice it is essential for car manufacturers and suppliers. It is often required as a mandatory prerequisite for a business relationship.

Automotive manufacturers are also subject to a large number of legal requirements, for example in relation to safety, sustainability and supply chains. In view of the high legal requirements, it is important that automotive manufacturers rely on reliable partners such as DMG MORI, who guarantee the highest possible product quality and compliant production.

Quality and flexibility for the mobility of tomorrow

Quality and flexibility are the key success factors for us in mastering the challenges of the automotive industry. As an experienced and broad-based partner, DMG MORI offers manufacturers end-to-end manufacturing solutions that enable high-quality products, the shortest possible production times and detailed quality control in automotive production. This reduces downtime, losses and costs.

The greatest possible flexibility is also important in order to survive in global competition and adapt quickly to changing conditions. This is why we offer companies not only a wide range of products that give manufacturers the necessary adaptability, but also comprehensive customer service and technical support from a single source. Our service includes an online service platform available at any time of day or night, a spindle service for maximum production reliability and comprehensive maintenance and repair services.

Sustainability is another elementary component of our corporate strategy and our mission. DMG MORI takes holistic responsibility for resources along the entire value chain - from raw materials to recycling - and relies on maximum energy efficiency in production.

With our promise of quality, we are responding to the changes in the automotive industry and supporting our customers as a long-standing, global competence partner in automotive engineering.

Your advantages as a DMG MORI customer

As a DMG MORI customer, you benefit from our many years of experience in the automotive environment and our broad know-how from intensive cooperation with industry and innovation leaders. In addition to machine tools, our complete solutions also include all associated processes and software solutions.

Quality and flexibility for the mobility of tomorrow

DMG MORI also offers a variety of technology cycles that have been specially developed for the requirements of the automotive industry:

- gearSKIVING: This technology enables the efficient production of gears and is particularly suitable for the production of transmission components in the automotive industry.

- ULTRASONIC IntoolSENSOR: Developed for the precision machining of hard-brittle materials such as glass and ceramics, which can be important for certain components in the automotive industry.

- cCLAMP: This technology cycle calculates the minimum required and maximum permitted clamping force to ensure secure clamping of the workpiece. This is particularly important for the machining of thin-walled components in automotive production.

- iJAW: Continuously monitors the clamping force and enables targeted maintenance to minimize unscheduled machine downtimes and reduce costs.

- gearHOBBING and gearSHAPING: These cycles are optimized for the production of gears and other transmission components that are widely used in the automotive industry.

Our continuous investment in innovation and development has made us a technology leader in the areas of digitization and automation. As an expert in production solutions for both combustion engines and electromobility, we cover a wide range of requirements.

Our presence in over 40 countries also ensures that our customers always receive the support they need.