DMG MORI Medical Excellence

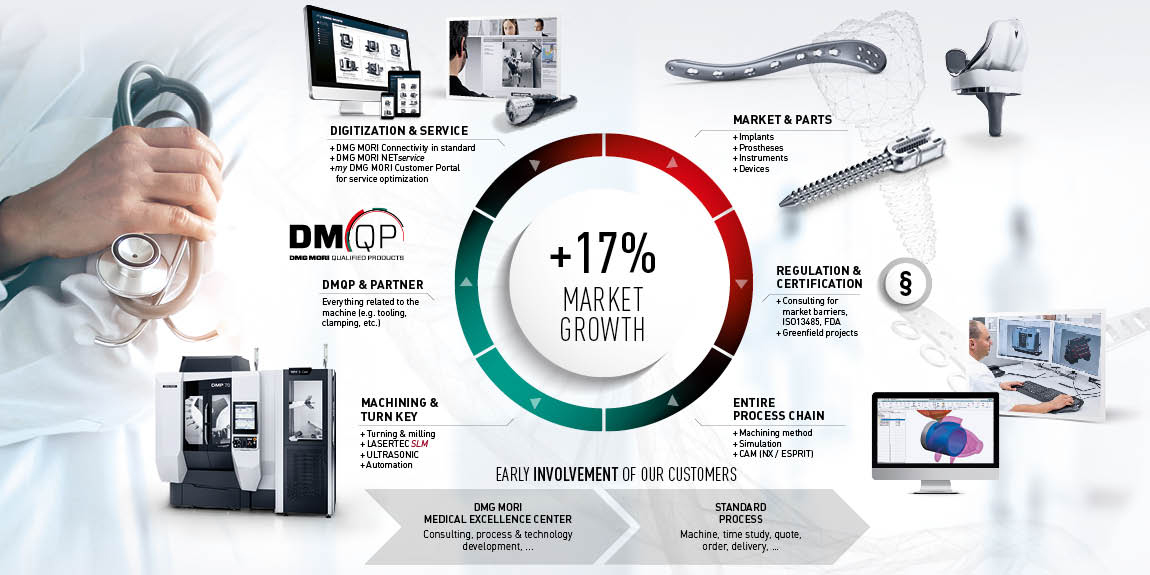

DMG MORI supports customers in all phases - from greenfield consulting, process development to consulting on regulatory issues, e.g. ISO13485 or FDA.

NEW IN 2021: MEDICAL CENTER OF EXCELLENCE IN CHICAGO

At our DMG MORI Solution Center in Chicago, we offer you the opportunity to obtain comprehensive information on this and other topics.

Medical at a glance:

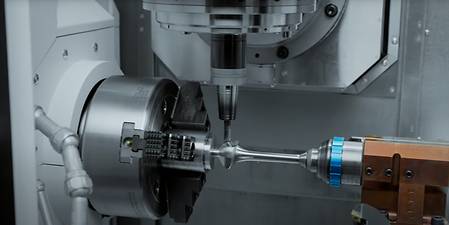

- Machining of the complete material mix:

- Degradable Mg alloys, e.g. DMP 70 with fire extinguishing system and two-stage flame detector

- High-strength plastics, stainless steel and titanium with speedMASTER spindles up to 30,000 rpm or HSC spindles up to 60,000 rpm

- Hard-brittle materials (e.g. ceramics) and composites with ULTRASONIC

- SMAs (shape memory alloys) or polymers: Developing reliable machining strategies

- Workpiece optimised automation:

- Flexible automation for a batch size of 1, e.g. for just-in-time production of custom-made patient implants

- Automation for mass production, e.g. for standardized components such as screws with the SPRINT or MULTISPRINT

- DMG MORI Technology Cycles, e.g. ATC for the best surface finish

Applications and Machines

Medical Excellence of DMG MORI

Based on its wide-ranging product portfolio, DMG MORI develops optimum manufacturing solutions for its customers from the medical technology sector. In the DMG MORI Medical Excellence Center, set up specifically for this purpose at DECKEL MAHO Seebach, the experts of the machine tool manufacturer realise innovative turnkey solutions for both industry giants as well as smaller companies and suppliers that enable cost-effective production. Engineers are involved early on in the development phase of our customer’s projects. So they learn a lot and integrate the knowledge thus gained in the construction of our machines and components in order to design ever more efficient manufacturing solutions.