SPRINT 420

Next generation of SWISSTYPE machines

Highlights

The future of production turning

- Complete machining of workpieces up to ø 51 × 600 mm

- Chuck part machining possible

- 17 m² footprint incl. barloader & chip conveyor

SWISSTYPEkit

- Short and long turning on one machine

- Extended spindle travel from from 125 to 360 mm

- Changeover time between short and long turning in < 30 minutes

State of the art tooling concept

- 35 tool positions on 3 independent linear carriers, up to 27 live tools

- Modular and fully pre-settable tool holder system ready for digital data exchange

Ready for automation

- Preparation for bar loader in standard

- Internal robot for handling chuck parts possible

Sample applications

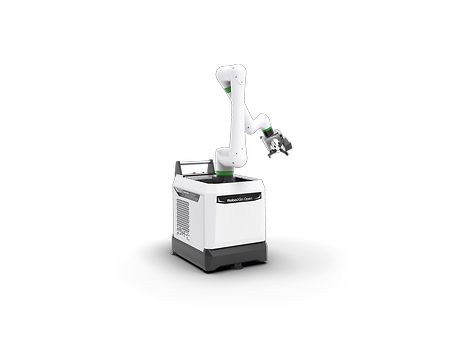

Automation

Standard automation and customised solutions in the VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customised automation solution for flexible manufacturing systems:

Flexible workpiece handling for small to medium batch sizes

- One app for uniform control of all Robo2Go variants, setting up a new workpiece < 5 minutes

- Robo2Go Turning, robot payload 12, 25 or 35 kg

- Rapid changeover from chuck to shaft parts

- Robo2Go Vision, robot payload 35 kg

- Robust 3D camera recognition, ideal for multi-job function

- Integrated in the machine control operation via CELOS APP: No need to change your NC programs!

- Intuitive usability thanks to dialog-guided software

- Creation of the process through predefined program modules via drag & drop: No robot programming knowledge necessary

- Setting up a new workpiece < 5 minutes

- Rapid changeover from chuck to shaft part storage

- Handling of shafts ø 20 – 170 mm and chuck parts ø 20 – 175 mm

- Three versions for all requirements: Robot payload 12 / 25 / 35 kg

- Stacking magazine

The storage expantion for your Robo2Go Turning

- 300 % higher capacity compared to standard

- Main time-parallel setup of the workpiece storage

- Multijob per drawer and within a drawer possible in the standard system

- Job management of all jobs via the Robo2Go Jobs app

- Robust 3D camera recognition, ideal for multijob function

- Infeed and outfeed of raw and finished parts by pallet

- Cylindrical chuck parts of ø 25 – 175 mm

Highly flexible and collaborative automation for workpieces up to 10 kg

- Freely movable workpiece handling, incl. robot and storage area on a trolley

- Workpieces up to 10 kg, or 5 kg x 2 with double gripper

- No infrastructure changes

- No safety fence necessary

- 600 × 900 mm footprint

- Collaborative robots, setup time <5 minutes*

- Direct teaching without robot knowledge

- Easy connection via Ethernet

- Two types of workpiece stockers can be selected

- Storage for up to 64 workpieces

- Blow-off device

- Regrip station

*When the optional tag position correction function is selected and when the machine / workpiece setup is already completed.

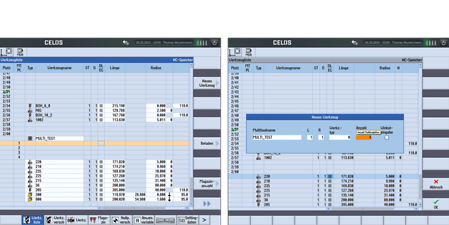

Control & software

- By pushing the associated key the X- axis and the Y-axis travel to the positive end-positions for external machining

- Ideally suited to prepare the work space for set-up and alternatively also as an emergency rescue function.

- Easy operation when setting up multi - channel machinery

- Possibilty of a fast response during external machining as a rescue function

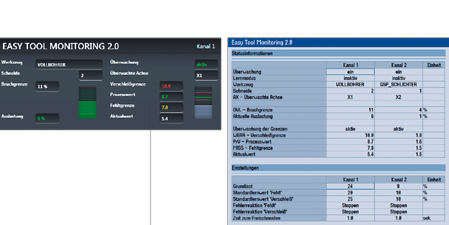

- Prevention of damage due to tool breakage or tool overload

- Sensorless with automated learning of load limits

- For turning, milling and drilling (up to 3 mm diameter)

- NEW: User interface on CELOS SideScreen

- NEW: Powerful algorithm for efficient monitoring after the first workpiece

- Protection Package: Perfect supplement to MPC Lathes. Price advantage (approx. 40%)

- Save the monitoring limits for each tool and every cutting edge in the program

- Productive complete processing

- Cost-effective gear cutting on standard machine with standard tools

- Flexible for different gear geometries

- Quality inspection in the process

- Program creation based on blank drawings and gear data

- Optimization of workpiece orientation e.g. after heat treatment

- Interface for coordinate measuring device (Klingenberg, Leitz, Zeiss)

- Efficient use of multi-tip turning tools with more than one cutting edge on turn & mill

- Several "sister tools" on one main tool holder

- Reduction of tool change times

- Saves tool magazine space

Service & training

Downloads & Technical Data

Special technical articles, analyses, and background information on topics that move our industry.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Get access to many useful digital functions and services and have all important data at a glance. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Unlock access to your Share Hub and many other functions and services. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

For general enquiries, please use our contact form.

For service and spare parts enquiries please use the my DMG MORI portal: https://us.mydmgmori.com/

Thank you very much for your interest in our products.

To download our brochures please fill in the form below.

If you accept the storage of cookies, this form appears only once during your visit.