HSC 20 linear

Compact, precise, reliable process with >2 g acceleration and spindle speeds up to 60,000 rpm

Max. X-axis travel

200 mm

7.9 in.

Max. Y-axis travel

220 mm

8.7 in.

Max. Z-axis travel

280 mm

11 in.

Max. workpiece diameter

200 mm

7.9 in.

Max. workpiece height

200 mm

7.9 in.

Max. workpiece weight

100 kg

220.5 lbs.

Control & software alternatives

SIEMENS

Highlights

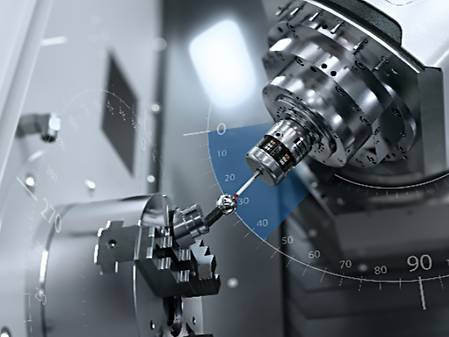

HSC machining with surface qualities of up to Ra < 0.0025 µin with best contour and fitting accuracy

- Powerful, water-cooled spindle variants from 42,000 rpm to 60,000 rpm

- Available with HSK-E32 / HSK-E40 tool holder, with active cooling

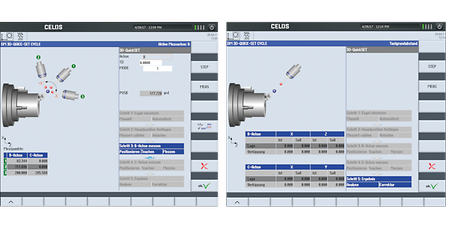

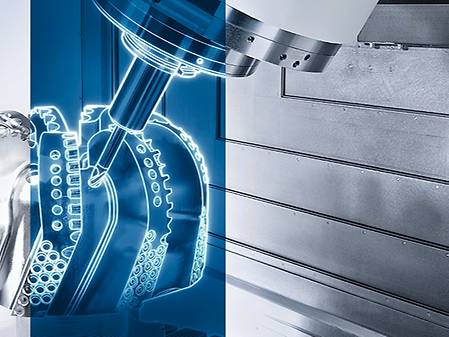

Compact 5-axis portal machine in gantry design with integrated NC swivelling / rotary table (A- / C-axis)

- Compact footprint of only 37.7 ft2 and gantry design (Y-portal) for optimized chip fall

- Optional NC-swivel-/ rotary table with -15° to 130° swivel range (A-axis), C-axis 360° infinite

- Ø 7.9 in clamping surface and 33.1 lb table load (5-axis), rigid table 14.6 in x 12.6 in and 220.5 lb (3-axis)

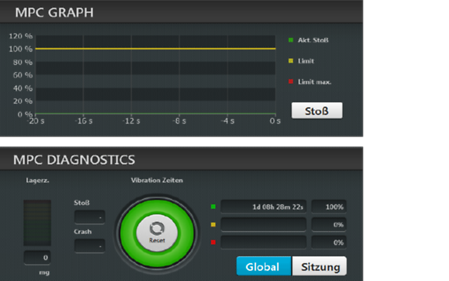

Highest dynamic with >2g acceleration and absolute longterm stability

- Linear drives in X / Y / Z with > 2 g acceleration

- 50% stronger drives in the A-axis

- Stable, FEM-optimized, vibration-damping mineral composite column

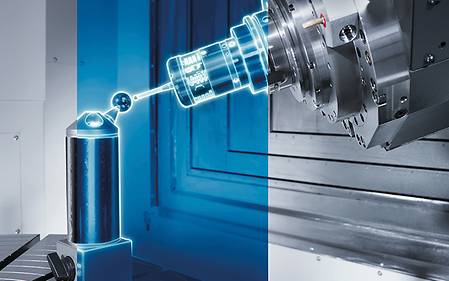

Integrated linear magazine PH 10 | 100 with max. 99 pallet places (max. 22 lb handling weight)

- Compact footprint with only 64.6 ft²

- Flexible integration of all available clamping systems

- Customer specific expansion modules available on request

Sample applications

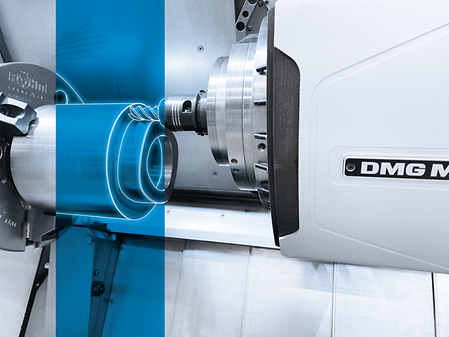

Automation

Standard automation and customized solutions in VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customized automation solution for flexible manufacturing systems: