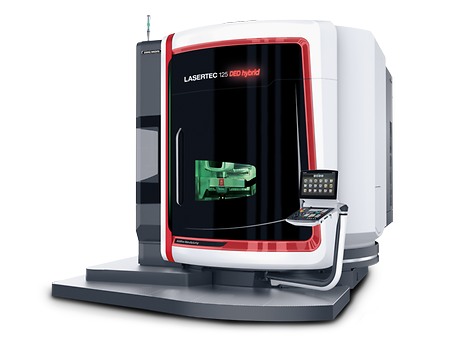

LASERTEC 125 DED hybrid

Hybrid Additive Manufacturing: Building, repairing and coating of high value metal parts up to 4,409 lbs.

Max. X-axis travel

1335 mm

52.6 in.

Max. Y-axis travel

1250 mm

49.2 in.

Max. Z-axis travel

900 mm

35.4 in.

Max. laser power

3000 W

3000 W

Max. workpiece weight

2000 kg

4409.2 lbs.

Highlights

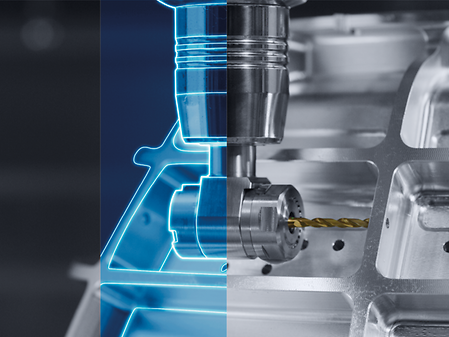

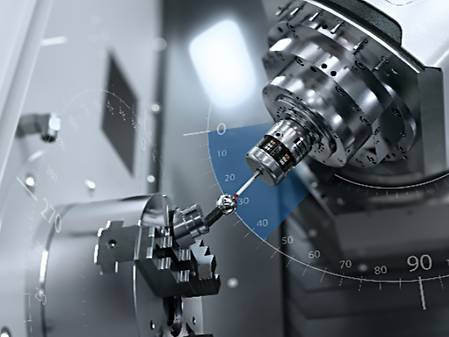

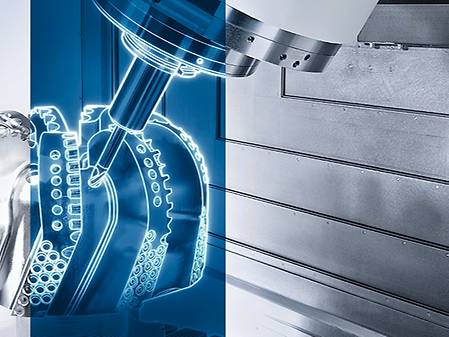

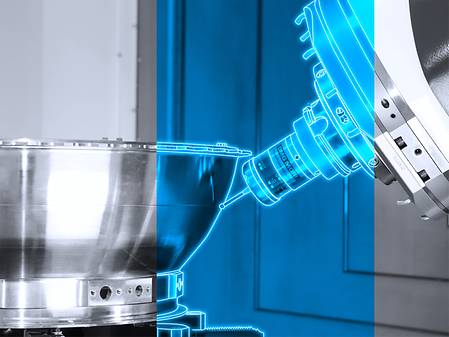

High flexibility of manufacturing processes by combining welding and milling on one machine for additive manufacture and repair

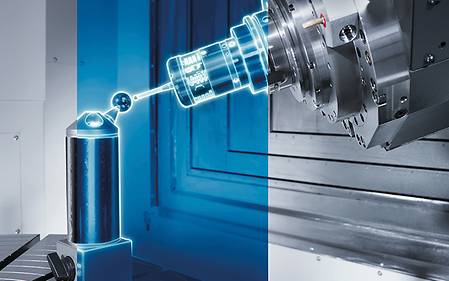

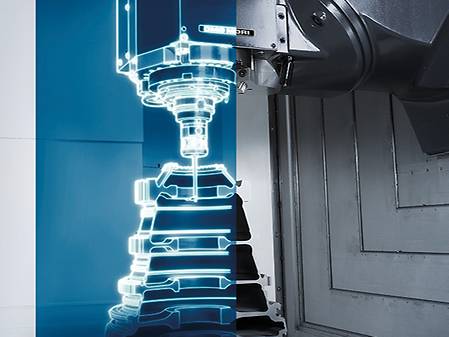

- The laser deposition head is handled by a fully automatic shuttle without manual intervention

- 5 axis material deposition by coaxial nozzle for homogeneous powder distribution, independent of direction of laser deposition welding

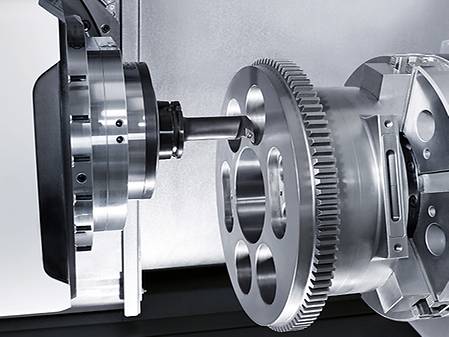

- Full 5-axis milling capability based on the monoBLOCK machine

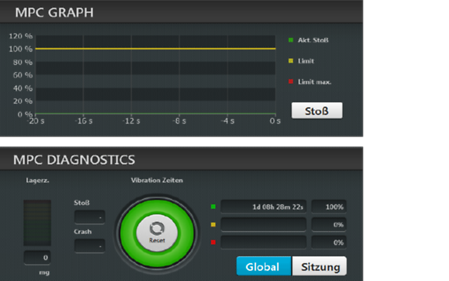

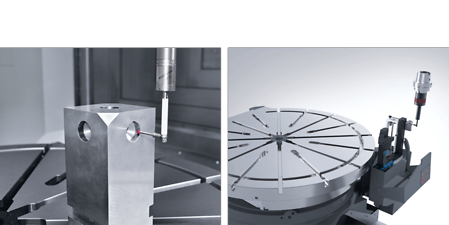

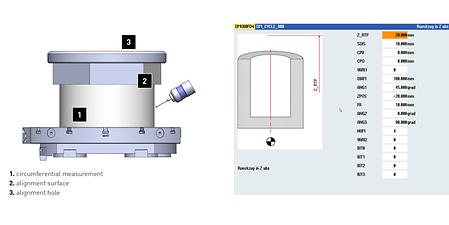

AM Assistant for the best process reliability and comprehensive traceability

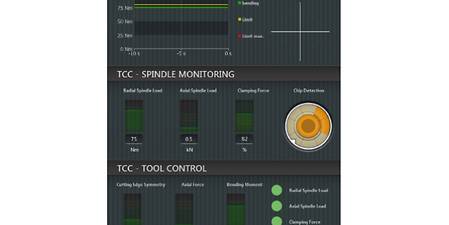

- Integrated thermal imaging camera for observation of the whole working area, adapive process control and constant monitoring of the working distance

- Powder feed rate sensor as well as automatic powder calibration.

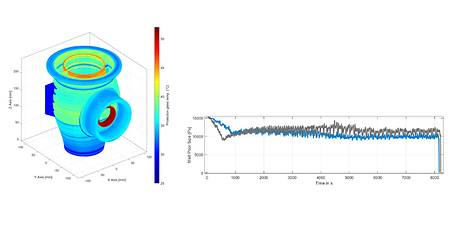

- AM Evaluator for visualisation of the relevant process data (e. g. meltpool size, powder mass flow) as a digital 3D-model as well as in the chronological sequence

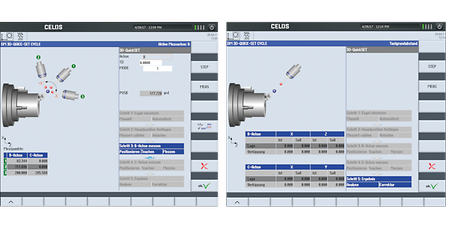

Siemens NX: Complete Hybrid CAD / CAM – Module for additive and subtractive programming

- One software package for the complete process chain (design, additive process, substractive machining, finishing)

- Exclusive LASERTEC build-up strategies - fully integrated in the CAD / CAM software incl. 3D-simulation of machine movements for collision prevention

- Change between additive and machining programming strategies all within one programming environment.

Using Multi-Materials and Gradient Materials for Improved Part Performance

- Selectively adding materials with more than 60 Rockwell to avoid heat treatment processes

- Improving cooling performance by using bronze material in the mould core

- Better materials and improved reliability in the repair process for increased service life

- Improved performance of exisitng tool designs by adding wear resistant coating

- Material gradients between hard and soft, magnetic and non-magnetic, etc.

Sample applications

Control & software

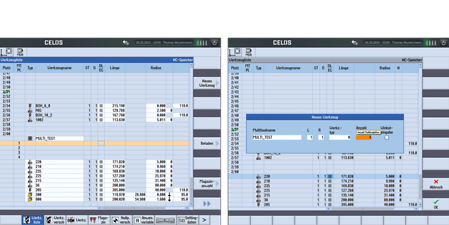

CELOS

Integrated digitization of the DMG MORI machines & the shop floor:

- CELOS Machine: APP-based user interface with access to all production-related information

- CELOS Manufacturing: 27 CELOS APPs for the optimal preparation & processing of orders

- Digital Factory: Continuous digital workflows from planning to production & service