MATRIS

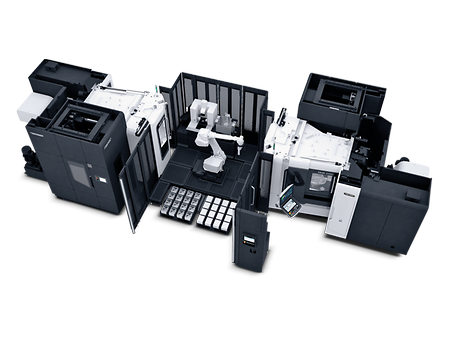

Flexible modular robot system for ≥ 1 machine

- Modular concept with standardized peripheral devices, e. g. washing, measuring or marking

- 80 % shorter setup time due to modular and standardized peripherals and robot programs

- Flexible adaptation to system changes including after installation

- Simple and easy operation via the MATRIS control system without programming

Highlights

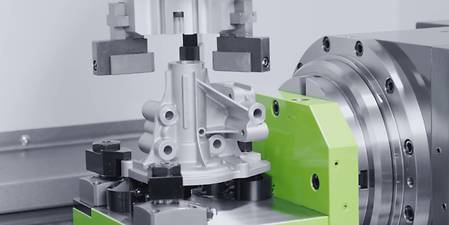

Highlights - Workpiece Handling

- Handling of workpieces up to ø 200 × 200 mm, 1 × 20 kg or 2 × 10 kg

- Stacking magazine:

- 14, 20 and 26 pallets: ø 150 × 120 mm, max. 35 kg per pallet

- 10 and 20 pallets: ø 200 × 200 mm, max. 75 kg per pallet

- Loading of oversized tooling in case of vertical machining center

- Available for 13 series, e. g. NLX, NTX, NHX, DMU, NMV, eVo, etc.

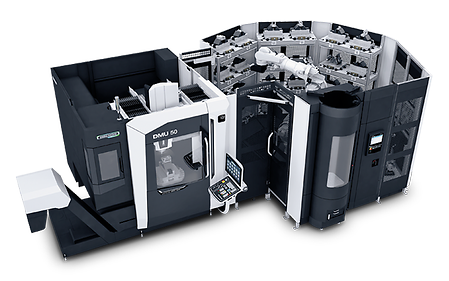

Highlights - Pallet Handling

- Ideal for the flexible production of 50 to 200 workpieces / day

- Space-saving pallet handling for up to 40 pallets

- 400 × 400 mm pallet size

- 150 kg transfer weight (workpiece and pallet)

- Integration of secondary processes such as deburring or marking possible

- Available for the CMX 50 U, CMX 70 U, DMU 50, DMU 65 monoBLOCK, CMX 600 V, CMX 800 V, CMX 1100 V

Technical Data

Max. workpiece weight lb.

Max. workpiece size in.

Max. number of pallets

2 × 11

ø 5.9 × 4.7; ø 7.8 × 5.9

14 / 20 / 26; 10 / 20

2 × 22.5

ø 5.9 × 4.7; ø 7.8 × 5.9

14 / 20 /26; 10 / 20

Machine

CTX 750 | 1250

CTX 750 | 2000

CTX 2500

CTX beta 800

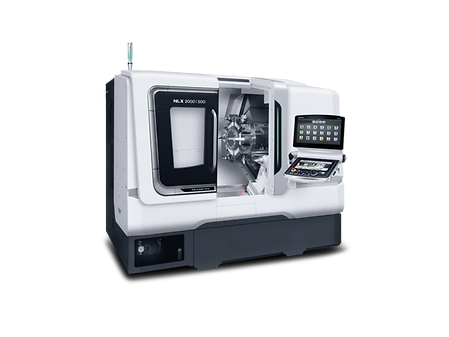

NLX 1500

NLX 2000

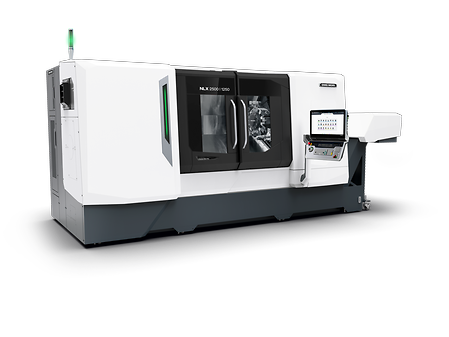

NLX 2500

NLX 2500 | 750 2nd Gen.

NLX 3000

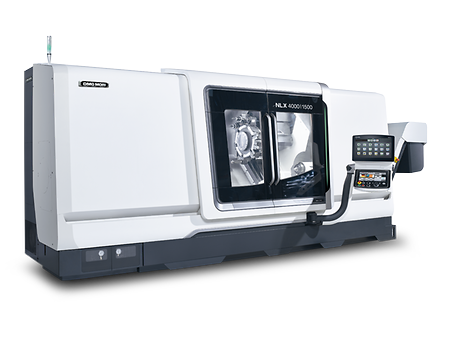

NLX 4000

NLX 6000

CLX 450 TC

CLX 550 TC

CTX beta 450 TC

CTX beta 800 TC

CTX beta 1250 TC

CTX beta 1250 TC 4A

CTX beta 2000 TC

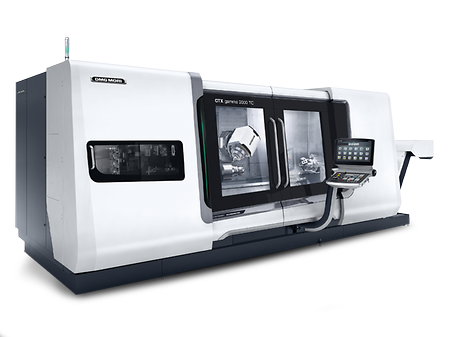

CTX gamma 1250 TC

CTX gamma 2000 TC

CTX gamma 3000 TC

NTX 500

NTX 1000

NTX 2000

NTX 2500

NTX 3000

ALX 1500

ALX 2000

ALX 2500

NZX 1500

NZX 2000

NZX 2500

CMX 600 V

CMX 800 V

CMX 1100 V

NVX 5060 2nd Gen.

NVX 5080 2nd Gen.

NVX 5100 2nd Gen.

i30 V

INH 63

INH 80

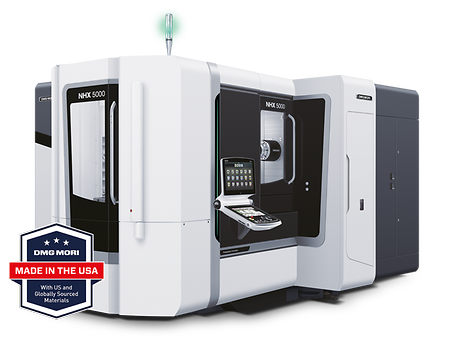

NHX 4000

NHX 5000

NHX 5500

i50 V

NHC 4000

NHC 5000

NHC 5500

NMV 5000 DCG

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

x

x

x

●

●

●

●

●

●

x

x

x

●

x

x

x

●

●

● available

x only MAPPS version

High rigid universal turning machine with up to 2,040 mm turning length

Ultimate Performance for Parts Machining

Ultimate Performance for Parts Machining

Ultimate Performance for Parts Machining

Ultimate Performance for Parts Machining

Elaborate and Dynamic Parts Machining

Large Turning Center Capable of Powerful Machining of Large-diameter Shafts

Better equipped - today and in the future

Turn & Mill complete machining with compactMASTER turn-mill spindle and a second tool carrier

Turn & mill machine for 6-sided complete machining

Turn & mill machine for 6-sided complete machining

Turn & mill machine for 6-sided complete machining

42,000 rpm compactMASTER TURN & MILL Spindle for high speed and micro machining

Covering Extensive Range of Machining Across All Fields

Covering Extensive Range of Machining Across All Fields

6-sided machining with Turn & Mill Spindle compactMASTER

Overwhelming quality by perfect performance

Precise Machining of High-performance Mass Production Parts

Precise Machining of High-performance Mass Production Parts

Overwhelming Manufacturing Capability Standing Out in Shaft & Flange Machining

The solution-based CMX V - from now on with IoTconnector and direct measuring system in standard

The solution-based CMX V - from now on with IoTconnector and direct measuring system in standard

The solution-based CMX V – now with IoTconnector and direct measuring system in standard

Best-ever high-precision vertical machining center

Best-ever high-precision vertical machining center

Best-ever high-precision vertical machining center

Compact body full of high-performance features

Horizontal machining center with highest stability, precision and dynamics

Horizontal machining center with highest stability, precision and dynamics

Horizontal machining center with highest stability, precision and dynamics

Horizontal machining center with highest stability, precision and dynamics

Fusing a diverse range of functions with elegant design

Optimum for mass production machining of cylinder heads and cylinder blocks

High-precision, 5-axes control vertical machining center

Hybrid Machining: Additive Manufacturing and Turning / Milling in one Machine

For the highest demands in the 5-axis universal range of workpieces up to Ø700 x 550 mm and 500 kg on 9 m²

Rebirth of DMG MORI’s bestseller – completely modernized

Base Machine for Automation for Every Shop Floor

Base Machine for Automation for Every Shop Floor

Precision, productivity and flexibility in compact body

Base Machine for Automation for Every Shop Floor

Precision, productivity and flexibility in compact body

Special technical articles, analyses, and background information on topics that move our industry.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Get access to many useful digital functions and services and have all important data at a glance. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Unlock access to your Share Hub and many other functions and services. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

For general enquiries, please use our contact form.

For service and spare parts enquiries please use the my DMG MORI portal: https://us.mydmgmori.com/

Thank you very much for your interest in our products.

To download our brochures please fill in the form below.

If you accept the storage of cookies, this form appears only once during your visit.