Pfronten production site

47° 34‘ 19.682“ N, 10° 33‘ 56.881“ O

Pfronten – Precision as a passion

Allgäu is one of the most popular vacation destinations in Germany. Close to Neuschwanstein Castle, Pfronten is only one of many towns in the area to offer cozy hostels as overnight accommodation. But it is extremely difficult to book a room throughout the entire region during the DMG MORI Open House at the beginning of the year. The success story of DMG MORI in Pfronten began in 1920 with the merger of five precision engineers. The quintet called its new, aspiring company Maho, which began to produce tool machines for their own use in 1950. They quickly came to the attention of larger companies, who ordered specially customized machines from Maho. In 1970, they therefore began to concentrate solely on this branch of business, acquired Graziano in Italy, went public, merged with Deckel and ultimately DMG with Gildemeister in 1994 – today they are part of DMG MORI.

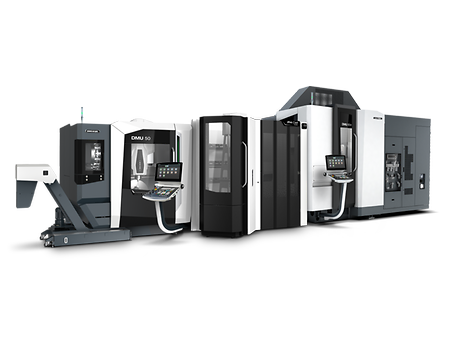

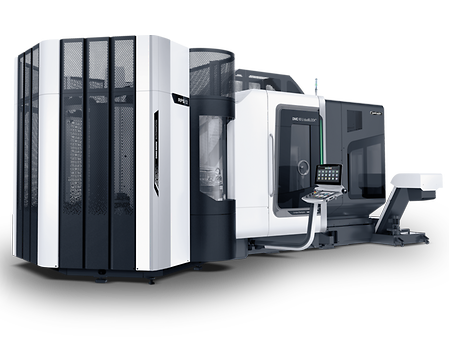

With around 1,600 employees and a total area of 149,000 m², Pfronten is one of the most important development and largest production plants of DMG MORI in Europe. As a milling expert, the factory alone produces 50 different types of machines from the versatile monoBLOCK series up to the XXL machines. Pfronten offers the capacity for around 1,500 machines to leave the factory every year for global distribution. The company DMG MORI Ultrasonic Lasertec GmbH is also located in Pfronten, and is responsible for advanced technologies in the group. The subsidiary company develops and builds its LASERTEC machines for high-precision applications in the field of laser texturing and drilling in Pfronten. DMG MORI Ultrasonic Lasertec GmbH sets the standard in additive manufacturing of metallic components with the LASERTEC 3D series.

Experts for a unique customer experience

In Pfronten, DMG MORI bundles comprehensive know-how for solutions in the aerospace sector as well as in tool and mold making. Our certified application technicians and engineers work together with customers at an early stage of projects to develop optimal manufacturing solutions. This close partnership promotes knowledge acquisition, and this new-found expertise can then be applied to future projects.

XXL Factory

The 5-axis machines in portal and gantry designs generate maximum stability and precision with the highest dynamics. Large traverses and high maximum table loads of up to 150 tonnes make it possible to machine workpieces for a wide range of universal applications. The thermal control concept produces maximum precision even in unfavourable ambient temperatures. The dual-table configuration allows the operator to be highly flexible and productive.

The following machines are built in the XXL Factory:

- DMU 600 P

- Portal design for ultimate stability and precision

- Highly stable cast iron machine bed and portal with excellent dampening characteristics

- High drive torque of up to 2,500 Nm for heavy machining

- Maximum flexibility through exchange heads

- DMU 600 Gantry

- Gantry design with a maximum table load of up to 150 tonnes

- Direct Drive technology in all axes (linear drives in X, Y and Z and torque drives in the A and C rotary axes) for unrivalled dynamics and surface quality

- High standard bandwidth and free from transmission frequencies

- Few contouring errors compared to drive technology with bevel gears / racks (approx. 30 % fewer)

- Maximum flexibility through exchange heads

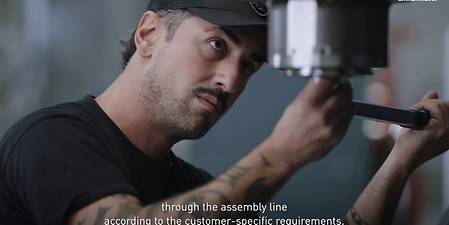

Innovative assembly concept

Investment in the future: With the monoBLOCK Excellence Factory, which opened in 2020, DMG MORI has revolutionized the production of 5-axis machining centers from the monoBLOCK series. At the heart of the new flow assembly are automated guided vehicles - AGVs. They are used to move the machines autonomously through the assembly stations at a continuous speed of 45 mm/minute. Optical navigation using the latest laser scanning technology ensures a continuous process. The complete model mix of the monoBLOCK series, including all series with pallet changer (DMC) and milling-turning pallets (FD), is produced in a flow assembly in 34 cycles. For a flexible, trouble-free process, the AGVs can also be freely navigated by remote control. The improved assembly concept has enabled a 30% increase in productivity. Customers also benefit from the correspondingly improved throughput times.