ULTRASONIC 50

Max. X-axis travel

650 mm

25.6 in.

Max. Y-axis travel

520 mm

20.5 in.

Max. Z-axis travel

475 mm

18.7 in.

Max. workpiece diameter

630 mm

24.8 in.

Max. workpiece height

500 mm

19.7 in.

Max. workpiece weight

300 kg

661.4 lbs.

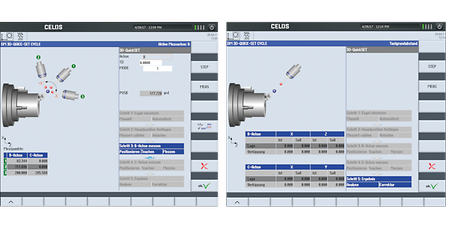

Control & software alternatives

SIEMENS

Highlights

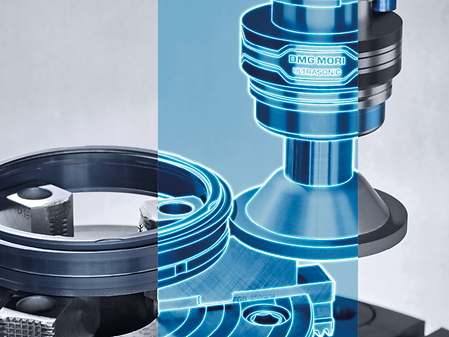

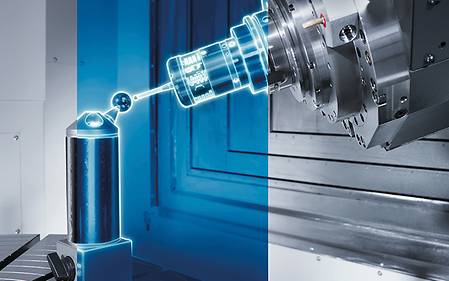

ULTRASONIC technology integration for an expanded machining portfolio

- Technology integration via HSK-A63 actuator system

- ULTRASONIC superimposition of the tool rotation with amplitudes up to > 0.254 µin.

- Automatic frequency detection -adaption, amplitude regulation and automatic feed adjustment

- Up to 50% reduced process forces due to ULTRASONIC allow for higher feeds, better surface finishes up to Ra < 0.00254 µin., and longer tool life

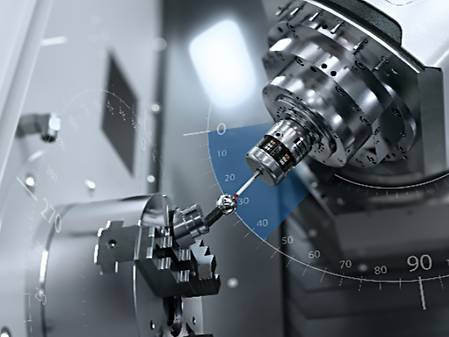

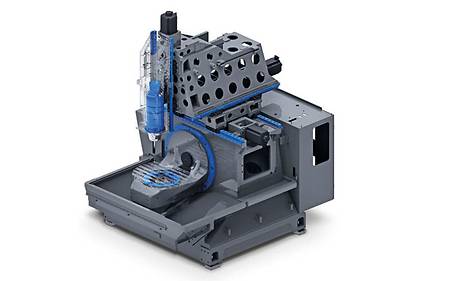

5-Axis Machining with up to 20,000 rpm

- speedMASTER 15,000 rpm with 28.2 hp and 81.9 ft lb in basic version

- speedMASTER 15,000 rpm with 61.7 hp and 147.5 ft lb optionally available

- speedMASTER 20,000 rpm with 46.9 hp and 95.9 ft lb optionally available

Swivel Rotary Table for 5-Axes Simultaneous Machining

- Table load up to 661.4 lb

- Swivel area of the B-axis -35°/+ 110° for highest flexibility

- Cooled table bearings for highest precision

Tool magazine with 30 pockets in basic version

- Loading of tools from the front even during machining

- Excellent visibility and accessibility

- 60 or 120 pockets optionally available

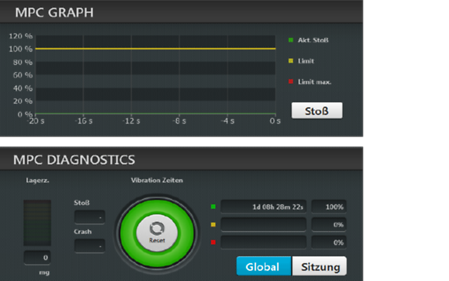

Precision

- comprehensive cooling concept for highest longterm precision

- one-piece machine bed

- direct driven ball screw drives

- direct path measuring systems in all axes

Sample applications

Automation

Standard automation and customized solutions in VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customized automation solution for flexible manufacturing systems: