ULTRASONIC 20 linear 3rd Generation

ULTRASONIC 20 linear - the most precise 5-axis simultaneous machine within DMG MORI

Max. X-axis travel

220 mm

8.7 in.

Max. Y-axis travel

370 mm

14.6 in.

Max. Z-axis travel

290 mm

11.4 in.

Max. workpiece length

302 mm

11.9 in.

Max. workpiece width

220 mm

8.7 in.

Max. workpiece diameter

220 mm

8.7 in.

Max. workpiece height

283 mm

11.1 in.

Max. workpiece weight

15 kg

33.1 lbs.

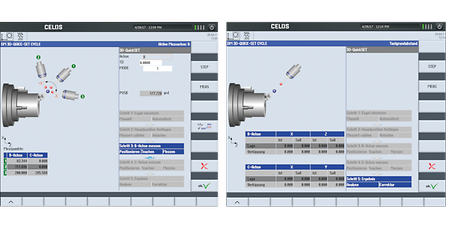

Control & software alternatives

SIEMENS

Highlights

ULTRASONIC 20 linear - Precise, compact and dynamic!

- Maximum dynamics and acceleration (up to 1,2 g), thanks to wear-free linear drives

- New FEM-optimized cast bed for maximal high long-term stability of the machine

- Finely tuned and highly sensitive temperature management

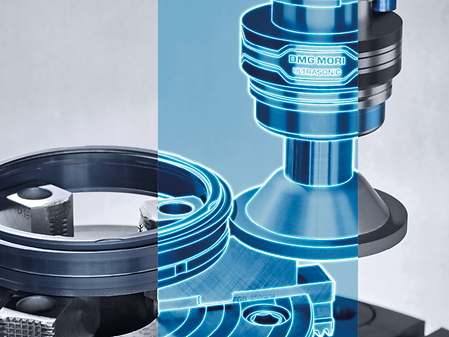

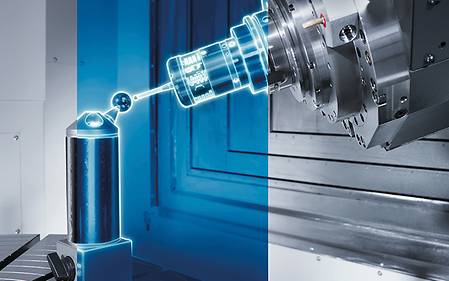

ULTRASONIC technology integration - reduced process forces for higher productivity

- Technology integration via HSK-E32 interface for ultrasonic superimposition of tool rotation with amplitudes of up to 15 µm

- Process forces reduced by up to 50% thanks to ULTRASONIC: higher feed rates, improved surface finishes down to Ra < 0.1 µm, longer tool service life depending on requirements

- Stable process window during machining for maximum reproducibility and consistent machining results.

- Ensuring the ULTRASONIC advantages even with non-optimal tools.

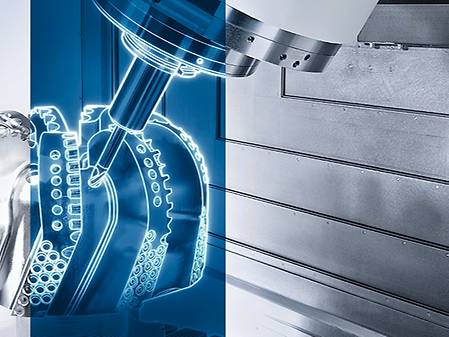

5-sided complete simulatnious machining of workpieces up to Ø 220 x 283 mm

- More travel path and larger working area:

- X = 220 mm

- Y = 370 mm

- Z = 290 mm

- Large swivel range of the A-axis: +130° to -93° with max. 15 kg table load

- Standard: 150 rpm in the C-axis

- Optional: 1,500 rpm in the C-axis

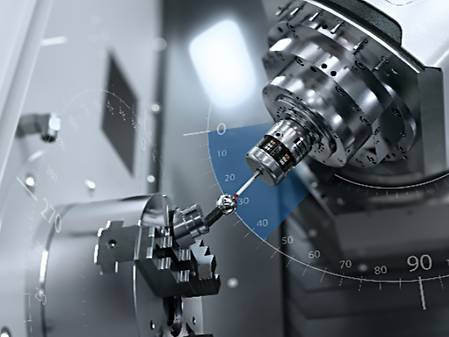

High-performance spindles for optimum machining performance with max. 60,000 rpm

- High frequency spindels: HSK-32: 42.000 rpm (60.000 rpm)

- Optionally with HSK-32 spindle with max. 60.000 rpm

Sample applications

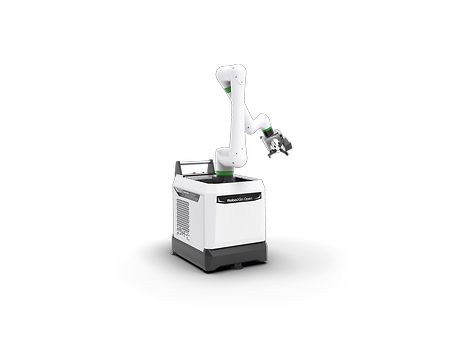

Automation

Standard automation and customised solutions in the VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customised automation solution for flexible manufacturing systems: