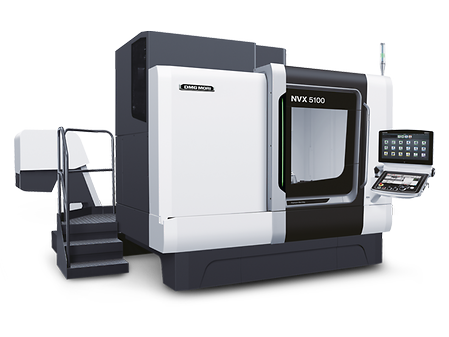

NVX 5100 2nd Generation

Best-ever high-precision vertical machining center

Max. X-axis travel

1050 mm

41.3 in.

Max. Y-axis travel

530 mm

20.9 in.

Max. Z-axis travel

510 mm

20.1 in.

Max. workpiece height

510 mm

20.1 in.

Max. workpiece weight

1200 kg

2645.5 lbs.

Max. workpiece length

1350 mm

53.1 in.

Max. workpiece width

600 mm

23.6 in.

Control & software alternatives

MAPPS Fanuc

Highlights

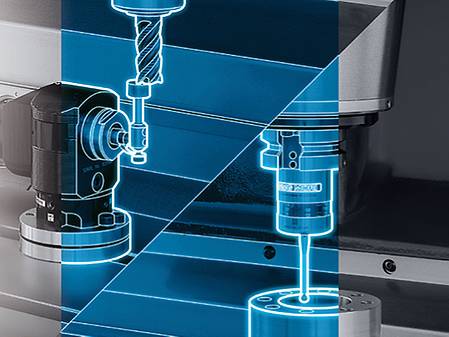

Unprecedented Rigidity and Accuracy - Ultimate Hybrid Structure

- Super-wide slideways (X- / Y-axis) to minimize quadrant projection

- High-rigidity roller guides (Z-axis)

- Optimized column shape substantially reduces thermal displacement

Best Chip Disposal Solution in the Industry

- Coolant tank for collecting casting sludge (option)

- Through-spindle coolant system (unit on coolant tank) <option>

- Chip conveyor (internal, spiral type) <option>

Pursuit of usability

- Accessibility - excellent access to the table and a wide door opening

- Loading and unloading with a crane - the ceiling part also opens

- By changing the spindle unit to a complete unit, which also includes the rear bearing units, we were able to reduce the spindle replacement time.

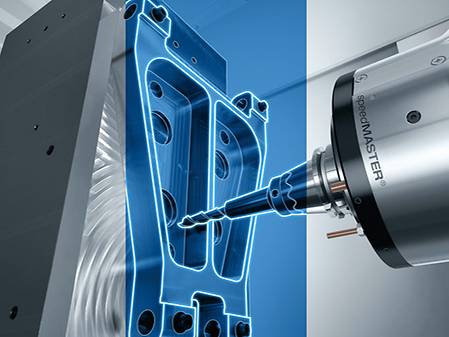

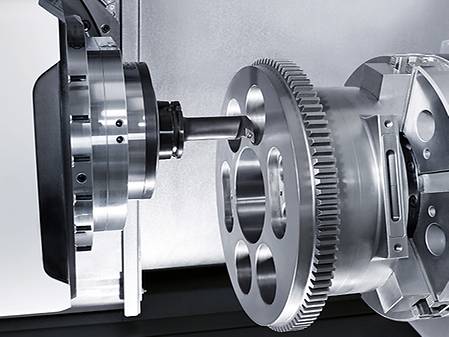

Outstanding machining capability, unmatched high-performance spindle

- World’s Best Spindle Technology

- No. 40 taper spindle achieves outstanding high-speed machining (speedMASTER)

- Stable high-accuracy machining made possible by drastically improved spindle run-out accuracy (speedMASTER)

- No. 50 taper spindle achieves outstanding heavy-duty cutting (powerMASTER)

- Thermal expansion compensation by spindle growth sensor (powerMASTER)

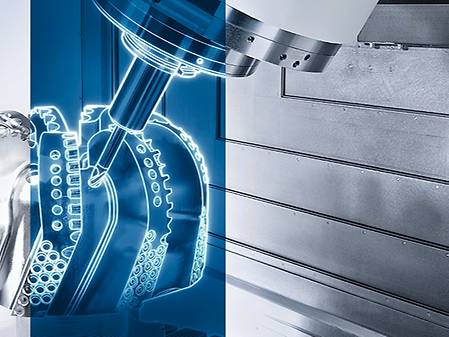

Sample applications

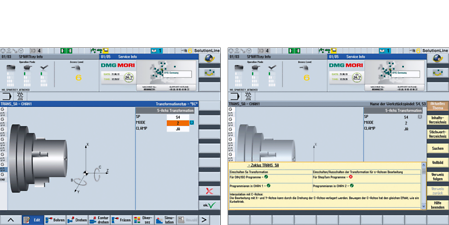

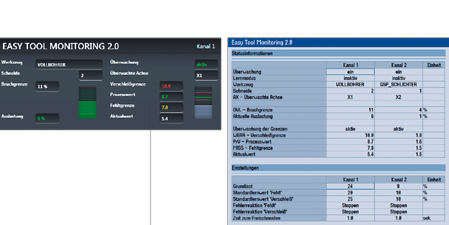

Control & software

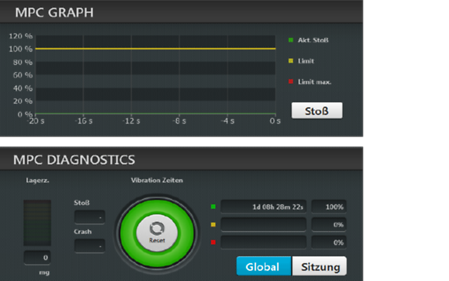

Experience the speed of digital transformation (DX)

Revolutionize your operations, unlock new opportunities, drive efficiency and sustainability by reducing power consumption – while gaining a powerful competitive advantage.

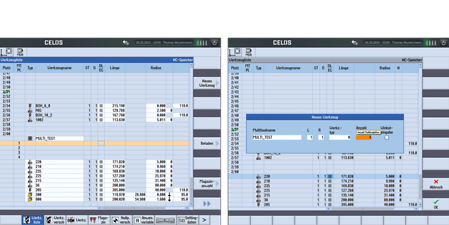

CELOS

Integrated digitization of the DMG MORI machines & the shop floor:

- CELOS Machine: APP-based user interface with access to all production-related information

- CELOS Manufacturing: 27 CELOS APPs for the optimal preparation & processing of orders

- Digital Factory: Continuous digital workflows from planning to production & service