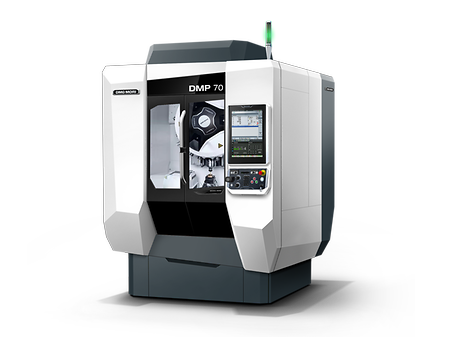

DMP 70

Vertical high speed machining center

Max. X-axis travel

700 mm

27.6 in.

Max. Y-axis travel

420 mm

16.5 in.

Max. Z-axis travel

380 mm

15 in.

Max. workpiece diameter

290 mm

11.4 in.

Max. workpiece height

580 mm

22.8 in.

Max. workpiece weight

400 kg

881.8 lbs.

Max. workpiece length

840 mm

33.1 in.

Max. workpiece width

420 mm

16.5 in.

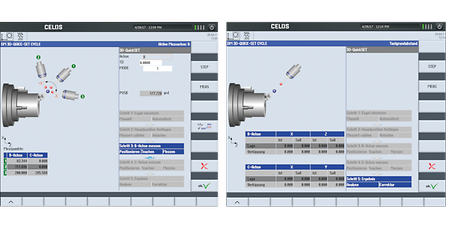

Control & software alternatives

SIEMENS

Highlights

Compact production machine for application in medical technologies, in the field of Job Shop, Aerospace and other challenging industries

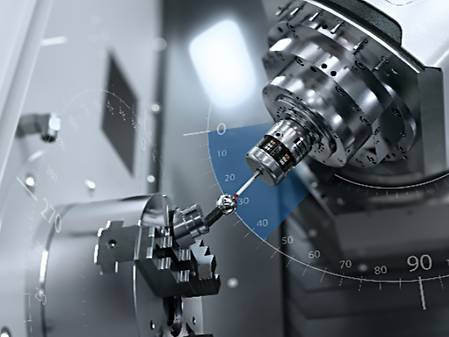

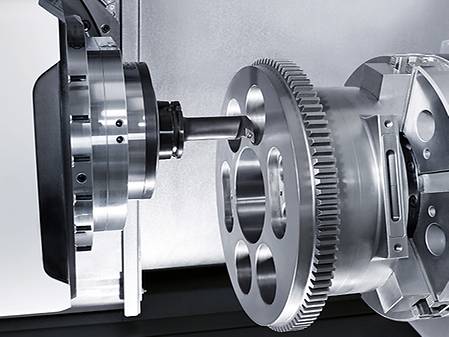

- 10,000 rpm inline spindle with up to 78 Nm; 24,000 rpm inline spindle with up to 48 Nm optional available

- Up to 2 g acceleration for quick chip-to-chip-time of only 1.5 seconds

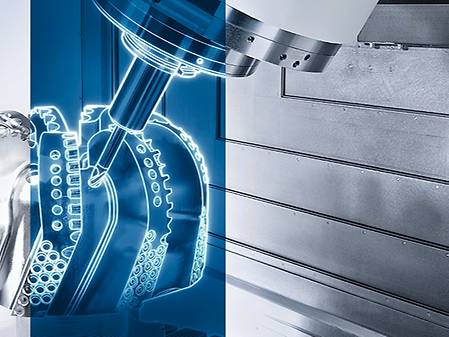

- Machining of complex parts based on optional 5-axis simultaneous ability

Highest precision and dynamics in the field of production

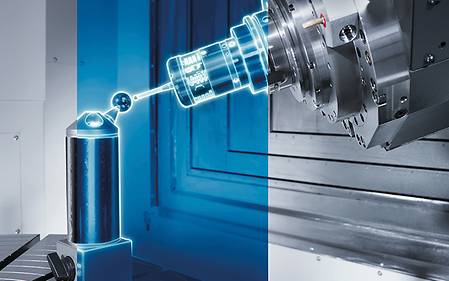

- Comprehensive cooling measures and direct absolute path measuring system in basic machine

- Highest rigidity and milling performance with rapid traverses of 60 m/min in all axes

- High-precision manufactured machine components ensure the highest accuracy

Productive machine design with perfect possibility of automation connectivity

- DMG MORI Stealth Design with inner doors to avoid chips falling outside of the machine

- Highest flexibility regarding the integration of automation from right side, left side and from the front of the machine

- Smallest space requirements of automation solutions, e.g. DMP 70 with WH 3 Cell needs only 8.8 m²

High productive machine concept

Highest precision, rigidity as well as maximum flexibility in the field 3-axis and 5-axis machining

- Minimal footprint of only 4.2 m²

- Highly dynamic tool magazine with a chip-to-chip time of only 1.5 seconds

- Maximum spindle stiffness based on spring preloaded bearings

- Comprehensive portfolio of chip conveyors and coolant systems