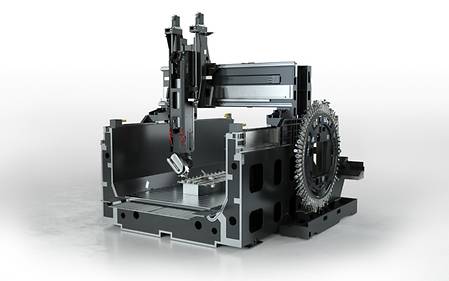

DMU 340 Gantry

Dynamic machining of large workpieces

Max. X-axis travel

6000 mm

236.2 in.

Max. Y-axis travel

2800 mm

110.2 in.

Max. Z-axis travel

1500 mm

59.1 in.

Max. workpiece height

1540 mm

60.6 in.

Max. workpiece weight

30000 kg

66138.7 lbs.

Max. workpiece length

7000 mm

275.6 in.

Max. workpiece width

3140 mm

123.6 in.

Control & software alternatives

SIEMENS

HEIDENHAIN

Highlights

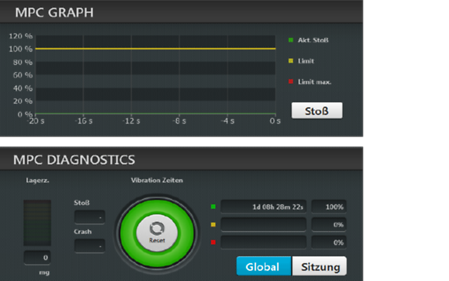

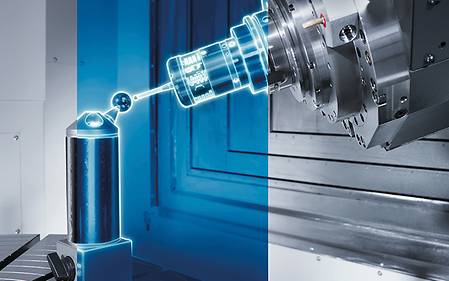

Precision

- Maximum accuracy through water-cooled feed drives

- Band filter unit with 2,500 l as standard

- Highest long-term accuracy due to cooled linear guideways and active spindle growth control.

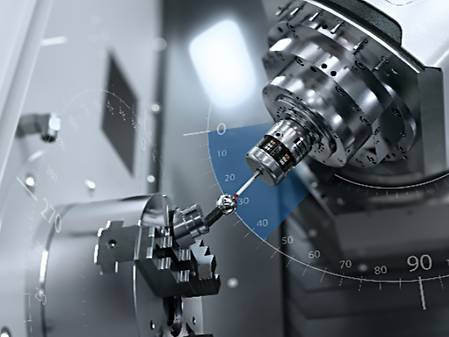

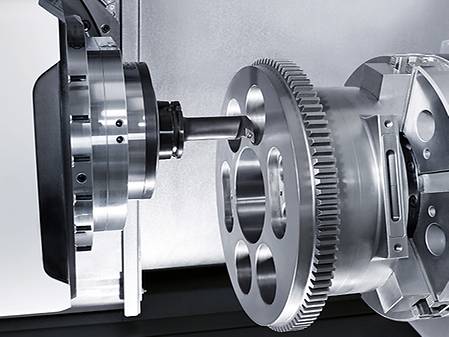

Performance

- High dynamics with feed speed up to 1,574.8 ipm

- High feed power up to 11,240 lbf

- Biggest spindle range in the market: powerMASTER motor spindle with up to 737.6 ft lb and torqueMASTER gear spindle with 1,327.6 ft lb

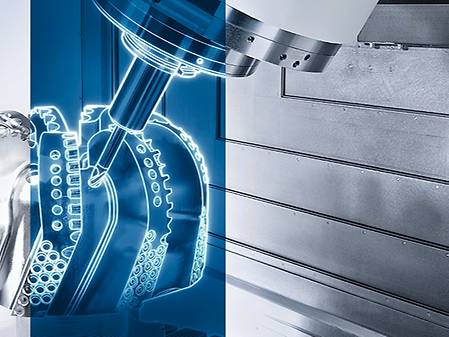

Efficiency

- Lower energy consumption through intelligent needs-based power units.

- Gantry design with vertically moving cross beam with hydraulic weight compensation.

- Fast innovative wheel type magazine with up to 243 tools with minimized footprint.

Highest rigidity and dynamics up to 16.4 ft/s²

- Thermosymmetrical construction

- 3-point support with an inherently stiff machine bed, no foundation required

- High temperature stability standard with positioning accuracy down to 0.38 µin

- Position accuracy down to 0.30 µin with accuracy pack option

- Short and continuous throat depth of milling head (no ram design)

Sample applications

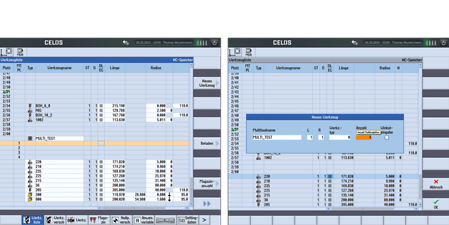

Control & software

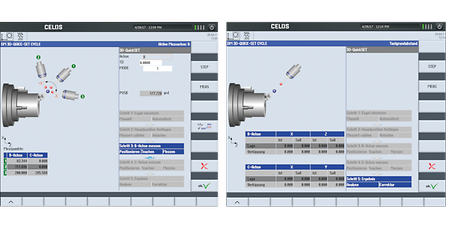

CELOS

Integrated digitization of the DMG MORI machines & the shop floor:

- CELOS Machine: APP-based user interface with access to all production-related information

- CELOS Manufacturing: 27 CELOS APPs for the optimal preparation & processing of orders

- Digital Factory: Continuous digital workflows from planning to production & service