DMG MORI gearMILL

- Productive complete processing

- Cost-effective gear cutting on standard machine with standard tools

- Flexible for different gear geometries

- Quality inspection in the process

Highlights

Customer Benefits

- Program creation based on blank drawings and gear data

- Optimization of workpiece orientation e.g. after heat treatment

- Interface for coordinate measuring device (Klingenberg, Leitz, Zeiss)

Downloads

Technical Data

● available

Vertical Machining Center for workpieces up to 4,409 lb and large Y-travel of 27.6 in

Vertical machining center with 72.8 in X-axis and max. 6,614 lb load capacity

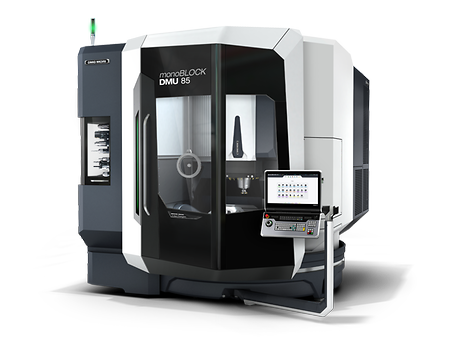

The monoBLOCK series has a machine concept for every sector

Traveling column machine of next generation for 5-axis simultaneous machining

Traveling column machine of next generation for 5-axis simultaneous machining

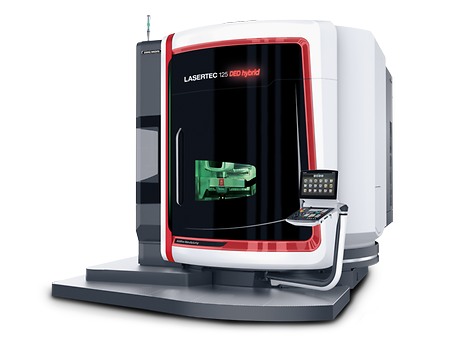

Hybrid Complete Machining: Additive Manufacturing and Milling in one machine

Hybrid Additive Manufacturing: Building, repairing and coating of high value metal parts up to 4,409 lbs.

Hybrid Machining: Additive Manufacturing and Turning / Milling in one Machine

Laser Metal Deposition & 5-axis machine

Traveling column machine of next generation for 5-axis simultaneous machining

Traveling column machine of next generation for 5-axis simultaneous machining

5-axis simultaneous machining of workpieces up to ø1,040 x 590 mm and 1,000 kg on 12.3 m²

The monoBLOCK series, a machine concept for every sector

5-axis simultaneous machining of workpieces up to ø1,040 x 590 mm and 1,500 kg on 12.3 m²

The monoBLOCK series, a machine concept for every sector

Special technical articles, analyses, and background information on topics that move our industry.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Get access to many useful digital functions and services and have all important data at a glance. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Unlock access to your Share Hub and many other functions and services. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

For general enquiries, please use our contact form.

For service and spare parts enquiries please use the my DMG MORI portal: https://us.mydmgmori.com/

Thank you very much for your interest in our products.

To download our brochures please fill in the form below.

If you accept the storage of cookies, this form appears only once during your visit.