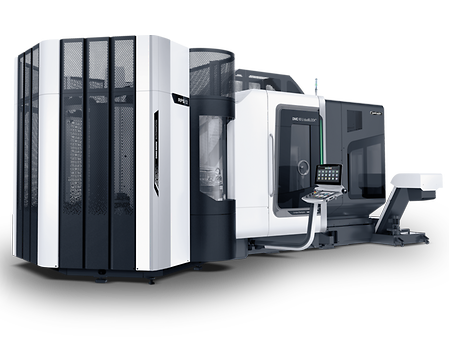

RPS duoBLOCK

RPS 6 / 7 / 12 - Machine-integrated automation with minimum space requirement

- Unmanned shifts due to circular storage system with up to 12 pallets

- Handling of workpieces up to ø 1,600 × 1,350 mm, 4,000 kg max.

- Reduction of non-productive time due to loading and unloading during production

- Easy operation via machine control with intuitive, integrated Pallet Manager software

- Pallet Master – for convenient and simple control of the automation directly via the machine control

Technical Data

Technical data

Workpiece

Max. workpiece weight lb.

Max. workpiece size in.

Capacity & Footprint

Max. number of pallet stations

RPS 6

DMC 65 monoBLOCK: 1,103

DMC 85 monoBLOCK: 1,764

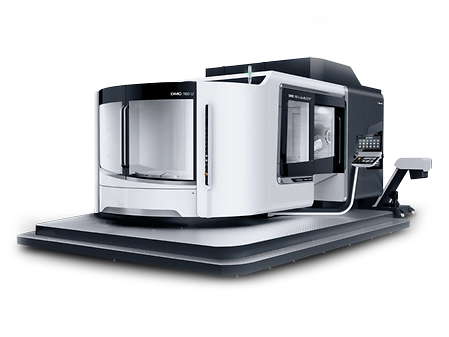

DMC 160 U duoBLOCK: 8,820

DMC 85 monoBLOCK: 1,764

DMC 160 U duoBLOCK: 8,820

DMC 65 monoBLOCK: ø 24.8 × 19.7

DMC 85 monoBLOCK: ø 31.5 × 23.2

DMC 160 U duoBLOCK:

ø 63.0 × 53.1

DMC 85 monoBLOCK: ø 31.5 × 23.2

DMC 160 U duoBLOCK:

ø 63.0 × 53.1

6

RPS 7

DMC 80 H linear: 1,985

DMC 60 H linear: 1,323

DMC 60 U duoBLOCK: 1,323

DMC 80 U duoBLOCK: 3,087

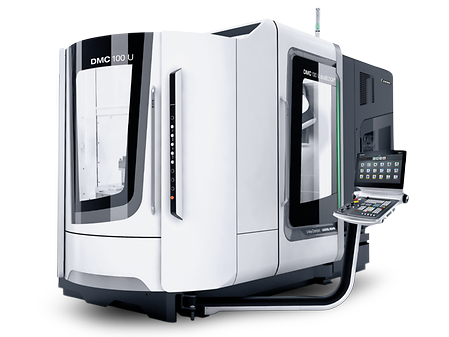

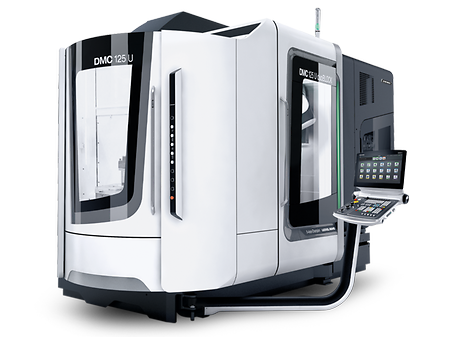

DMC 100 / 125 U duoBLOCK: 4,410

DMC 60 H linear: 1,323

DMC 60 U duoBLOCK: 1,323

DMC 80 U duoBLOCK: 3,087

DMC 100 / 125 U duoBLOCK: 4,410

DMC 60 H linear: ø 31.5 × 4.1

DMC 80 H linear: ø 39.4 × 43.3

DMC 60 U duoBLOCK: ø 24.8 × 33.5

DMC 80 U duoBLOCK: ø 35.4 × 5.7

DMC 100 U duoBLOCK: ø 39.4 × 63.0

DMC 125 U duoBLOCK: ø 49.2 × 63.0

DMC 80 H linear: ø 39.4 × 43.3

DMC 60 U duoBLOCK: ø 24.8 × 33.5

DMC 80 U duoBLOCK: ø 35.4 × 5.7

DMC 100 U duoBLOCK: ø 39.4 × 63.0

DMC 125 U duoBLOCK: ø 49.2 × 63.0

7

RPS 12

DMC 80 H linear: 1,985

DMC 60 H linear: 1,323

DMC 60 U duoBLOCK: 1,323

DMC 80 U duoBLOCK: 3,087

DMC 100 / 125 U duoBLOCK: 4,410

DMC 60 H linear: 1,323

DMC 60 U duoBLOCK: 1,323

DMC 80 U duoBLOCK: 3,087

DMC 100 / 125 U duoBLOCK: 4,410

DMC 60 H linear: ø 31.5 × 4.1

DMC 80 H linear: ø 39.4 × 43.3

DMC 60 U duoBLOCK: ø 24.8 × 33.5

DMC 80 U duoBLOCK: ø 35.4 × 5.7

DMC 100 U duoBLOCK: ø 39.4 × 63.0

DMC 125 U duoBLOCK: ø 49.2 × 63.0

DMC 80 H linear: ø 39.4 × 43.3

DMC 60 U duoBLOCK: ø 24.8 × 33.5

DMC 80 U duoBLOCK: ø 35.4 × 5.7

DMC 100 U duoBLOCK: ø 39.4 × 63.0

DMC 125 U duoBLOCK: ø 49.2 × 63.0

12

Machine

DMC 80 U (FD) duoBLOCK

DMC 100 U (FD) duoBLOCK

DMC 125 U (FD) duoBLOCK

DMC 160 U (FD) duoBLOCK

RPS 6

●

RPS 7

●

●

●

RPS 12

●

●

●

● available