powerMASTER spindle with up to 1,042 ft lbs.

The NHX 6300 2nd Generation impresses in horizontal machining with improved rigidity, high-performance powerMASTER spindles, shorter machining times thanks to its FANUC control and innovative chip removal.

- Significantly increased machine rigidity, ideal for heavy-duty machining:

- 462 cm³/min titanium (Inserted end mill cutter ø 3 in.)

- 0.5 in. cut depth in grey cast iron (EN-GJS-450, ø 6 in. cutter head, 5 in. cut width)

- Optional powerMASTER spindle with 1,042 ft-lbs. or 16,000 rpm

- SmartSCALE measuring system from MAGNESCALE, with 0.005 μ resolution in all linear axes in the standard version

- CELOS with MAPPS on FANUC

With experience gained from over 6,000 installed NH and NHX machines, DMG MORI will showcase the NHX 6300 2nd Generation at IMTS in Chicago. The NHX series has been further optimized to complement market demands. The powerMASTER spindle and improved rigidity of the NHX 6300 2nd Generation ensure unparalleled cutting performance and precision required in demanding applications such as automotive and general mechanical engineering. Users achieve shorter machining times thanks to the new FANUC control, while chip-removal and cleaning of the coolant enable reliable and continuous operation, even for high metal-removal rates as is the case with cylinder heads and gear housings.

“With its enormous stability and high cutting performance, the NHX 6300 2nd Generation excels in the machining of cast components,” says Mitsuru Taga, General Manager of Horizontal Machining Centers in Iga, about the NHX model from DMG MORI. The design of the machine’s bed and base has been given an even more stable construction than the predecessor model and roller guides have been installed on all axes. This NHX model achieves a rapid traverse of 60 m/min on axes strokes of 41 x 35 x 41 inches (X / Y / Z). The NC rotary table of the smaller machine is designed for pallets up to 20 x 20 inches, with workpiece height of 43 inches, and max. loading capacity of 2,205 lbs. The NHX 6300 2nd Generation offers space for pallets up to 25 x 25 inches, a workpiece height of 51 inches, and max. loading capacity of 3307 lbs.

The wheel magazine with space for 60 tools ensures high productivity with shorter setup times. Optional magazine solutions are designed for up to 330 tools. The tool length is up to 25 inches. The reliable tool changes achieve chip-to-chip times of less than five seconds.

A setup station enables preparation of the next job parallel to primary machining. In addition, the NHX 6300 2nd Generation can also be connected to a linear pallet pool (LPP). Up to eight machines can be linked with this system, offering space for maximum 99 pallets, which are directed to up to five setup stations.

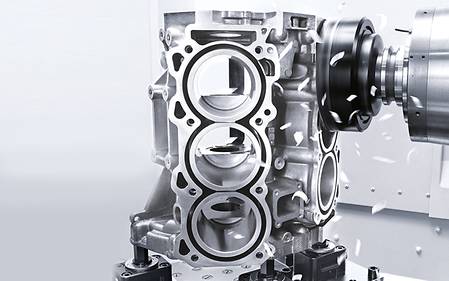

powerMASTER for every application

Even in its standard version, the NHX 6300 2nd Generation is equipped with a powerMASTER spindle with a max speed of 12,000 rpm and max torque of 595 ft lbs torque. The high-torque powerMASTER spindle with up to 1,042 ft lbs of torque is also available for demanding heavy-duty machining. A third version from the powerMASTER range has a max speed of 16,000 rpm and is geared towards customers who need higher speeds for even better surface finishes.

Just like the stability and powerful spindles, the direct measuring system from MAGNESCALE also contributes to the higher precision of the horizontal machining center. The same applies to the optional coolant temperature control with which DMG MORI achieves a high level of thermal stability.

Coolant cleaning in the standard version

The particularly fine chips produced in machining of cast parts give rise to a high volume of sludge. DMG MORI has combined chip removal with a cleaning system for the coolant. A filter collects the sludge while the chips are being removed. This is then led into the 320 gallon coolant tank where a nozzle agitates the fluid and filters out the impurities. Over 99 percent of the sludge is removed in this way, which reduces manual cleaning to a minimum, significantly reduces wear of the coolant pump, increases the useful life of the coolant, and therefore the service life of the tools.

FANUC control for shorter machining times

By using a FANUC control, DMG MORI has managed to considerably reduce the throughput times of the NHX 6300 2nd Generation. This user-friendly control supports the user during setup by creating programs and predicting potential program errors. In addition, the CELOS app-based control and user interface enables consistent administration, documentation, and visualization of orders, processes and machine data.

Contact us for all issues related to DMG MORI technical press.