THE NEW DMF 200 | 8

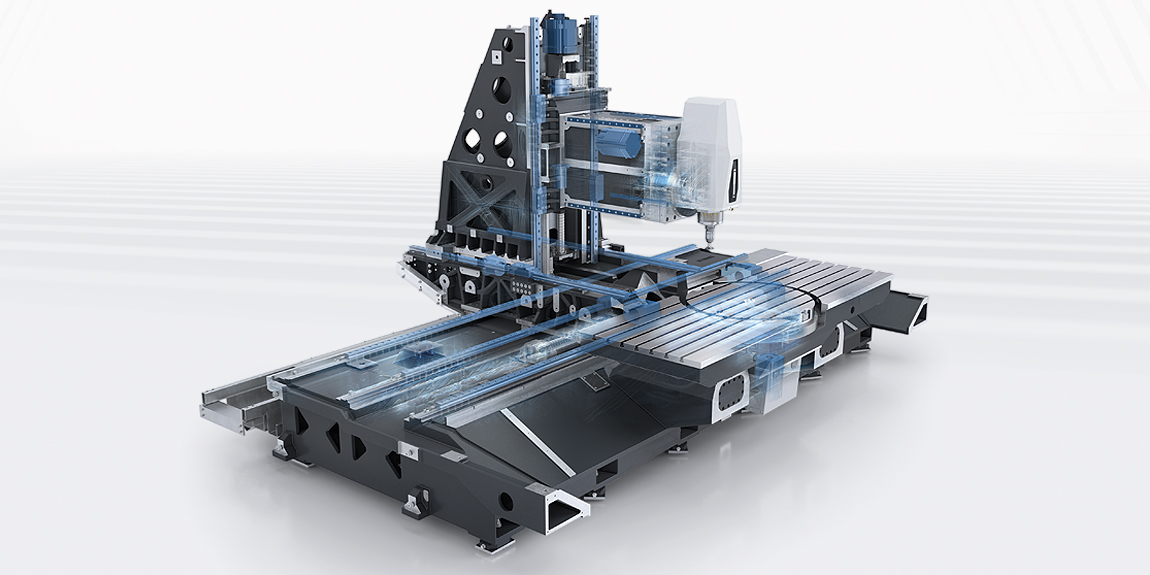

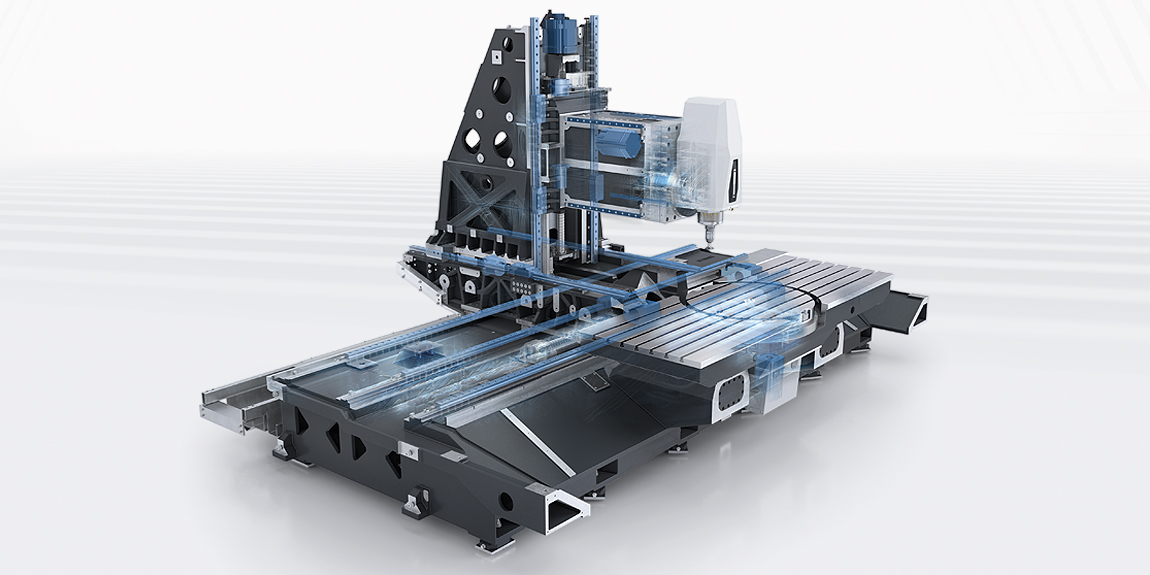

THE NEW TRAVELING COLUMN SERIES

- Maximized rigidity thanks to 3 linear guideways in the X-axis

- Reliable milling performance thanks to consistent overhang

- Optimal surface finish and accuracy thanks to direct drive in the Y-axis and Z-axis and integrated cooling

- Maximum flexibility when machining thanks to the B-axis milling head with ± 120° swivel range

- Large work area with travels of X = 2,000 / Y = 800 / Z = 850 mm

- Unique and innovative tool change, fast, collision free and with process reliability behind the work table

3 LINEAR GUIDEWAYS IN THE X-AXIS

The 3 linear guideways in the X-axis, thermal stability through holistic cooling and direct drives enable optimal surface finish and accuracy.

Fabian Suckert - Member of the management at DECKEL MAHO Seebach

DMF 200 | 8 WITH PH CELL*

NEW SOLUTION

FOR NEW POSSIBILITIES

- Unparalleled increase in productivity thanks to maximum utilization of the DMF machine

- 5-axis simultaneous machining of components with a pallet size of up to 500 × 500 mm

- Simple integration thanks to PH Cell modular automation system

- Up to 40 pallet positions possible *available from Q2 / 2021

*available from Q2 / 2021

PACKAGED EXPERTIZE IN TRAVELING COLUMNS

- Completion of the DMF series:

Integration of DMC V machines with traveling column and 700 mm Y-axis- Universal options and expansion stages, e. g. spindles and tables

- Pooling of expertize in traveling columns at DMG MORI in Seebach:

An integrated concept based on a modular system - DMF V: 3-axis vertical machining (X-axis: 1,150 to 1,850 mm)

- DMF: 5-axis simultaneous machining * (X-axis: 2,000 to 3,600 mm)

Read more now

Special technical articles, analyses, and background information on topics that move our industry.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Discover exclusive content with your DMG MORI Account.

Activate technical data now

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Activate download now

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Register now and unlock exclusive content

Get access to many useful digital functions and services and have all important data at a glance. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Login now to access your Share Hub

Unlock access to your Share Hub and many other functions and services. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Activate history now

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Activate favorites now

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.

Activate favorites now

- Unlimited product experience — unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, and blog articles with deep insights into the DMG MORI product world.

- Personalized access to other DMG MORI Platforms, including Event Platform, Media Library, and much more.

Learn more about the DMG MORI Account.